Method for Preventing Adhesion of Adhesion Using Forced Film Type Fluid Treatment Device

A technology for fluid treatment and treatment of objects, which is applied in the direction of mixers with rotating stirring devices, mixing methods, chemical instruments and methods, etc., and can solve the problems of preventing methods from being disclosed and unable to make particles stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0102] (Examples 1-3, Comparative Examples 1-3) Production of Quinacridone Nanoparticles

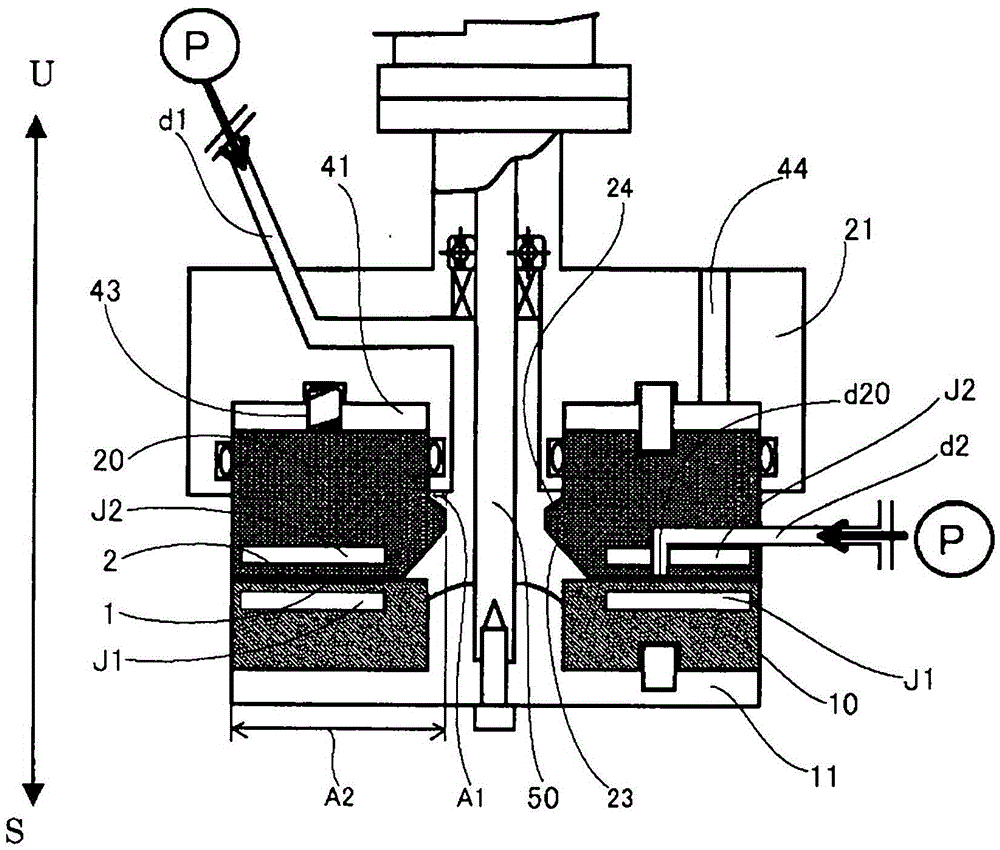

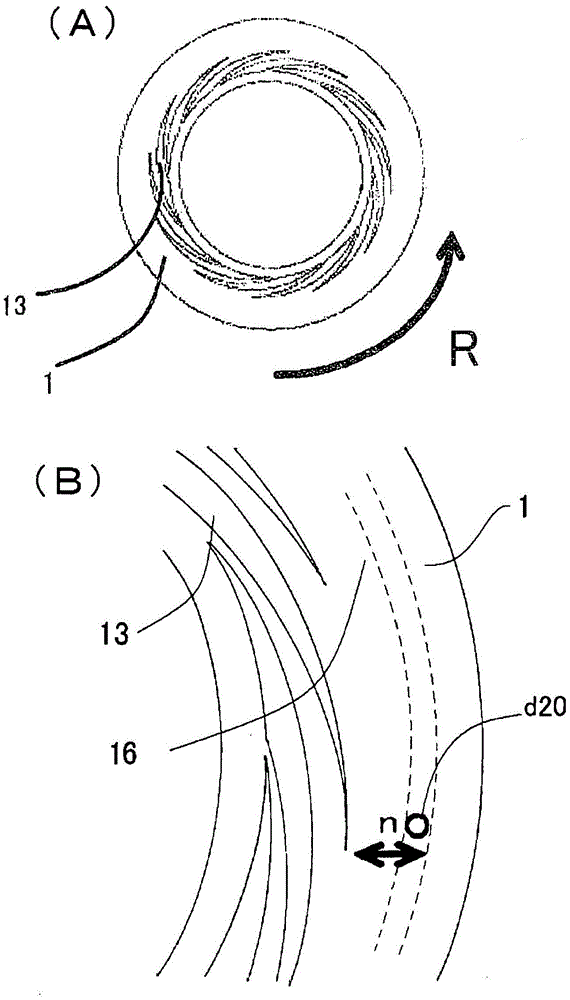

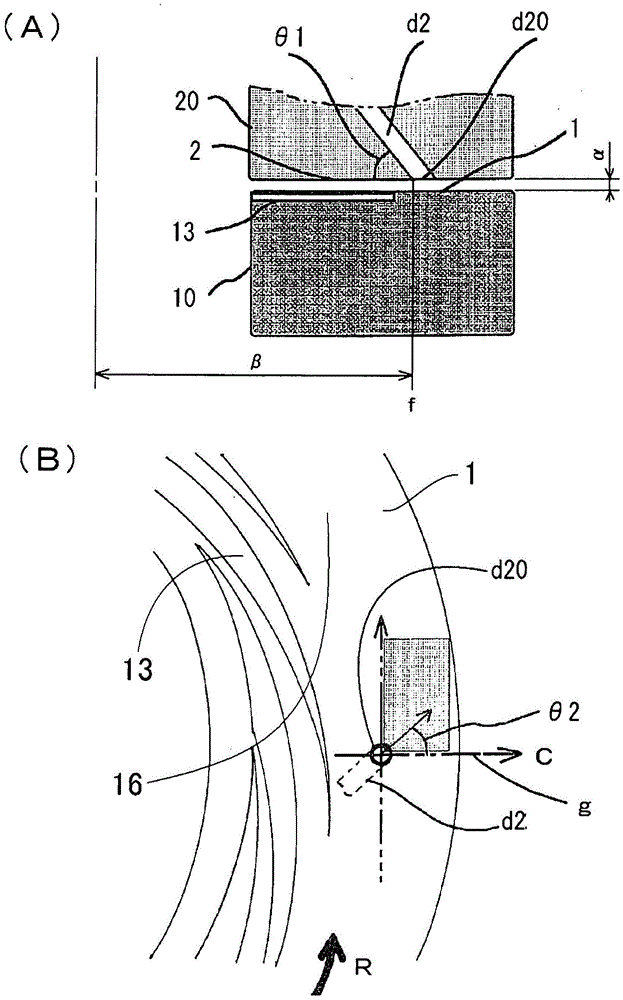

[0103] Such as figure 1 As shown in , in the thin film fluid formed between the processing surfaces 1 and 2 with at least one of the processing surfaces that are arranged oppositely and can rotate relative to the other, uniform diffusion, agitation, and mixing are used. A reaction device in which a quinacridone solution in which an organic pigment quinacridone pigment (C.I. PigmentViolet 19, hereinafter PV-19) was dissolved in concentrated sulfuric acid was mixed with methanol, and the precipitation reaction was carried out in a thin film fluid.

[0104] A 2.0wt% PV-19 solution in which PV-19 powder is dissolved in concentrated sulfuric acid as the first fluid, that is, a raw material fluid, is fed from the center at supply pressure / back pressure = 0.350MPa / 0.02MPa, and methanol is used as the second fluid Introduce to processing surface 1 and 2. (speed: 1500rpm)

[0105] The first fl...

Embodiment 4~6、 comparative example 4~6

[0112] (Examples 4-6, Comparative Examples 4-6) Production of tin nanoparticles

[0113] Such as figure 1 As shown in , in the thin film fluid formed between the processing surfaces 1 and 2 that have oppositely arranged accessible and separable processing surfaces, at least one of which rotates relative to the other, uniform diffusion, agitation, Mixed reaction apparatus, the tin chloride solution that dissolves tin chloride in methanol, and in the mixed solvent of methanol and toluene dissolve the sodium borohydride that is as reducing agent and the Chio Calcol 08 (Kao Co., Ltd. system) mixed with reducing agent solution, and the reduction reaction is carried out in the thin film fluid.

[0114] A 5.3wt% tin chloride solution dissolved in methanol as the first fluid, that is, a raw material fluid, is fed from the center at supply pressure / back pressure = 0.300MPa / 0.02MPa, and the reducing agent solution is used as the second fluid Introduce to processing surface 1 and 2. (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com