A kind of method for preparing polypropylene hollow fiber porous membrane

A technology for polypropylene and porous membranes, which is applied in the preparation of porous polypropylene hollow fiber membranes with a sponge-like structure, and in the field of preparing polypropylene hollow fiber porous membranes. Membrane, non-environmental protection and other issues, to achieve the effect of reducing production costs, shortening the production cycle, and promoting recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The technical scheme of preparing polypropylene hollow fiber porous membrane of the present invention is as follows:

[0023] 1) Continuously add 20% to 40% polypropylene by mass to the first heating section of the co-rotating twin-screw extruder through the hopper, and continuously add 80% to 60% by mass diluent to the co-rotating twin-screw extruder from the side In the remaining one or more heating sections of the twin-screw extruder, the co-rotating twin-screw extruder adopts at least 4 heating sections along the screw extrusion direction; the diluent is triethyl phosphate, tributyl phosphate , trioctyl phosphate, lauryl alcohol, cetyl alcohol, stearyl alcohol, diethylene glycol, octadecanoic acid, diphenylmethane, eicosane, myristic acid, oleic acid, benzophenone, water Methyl Cylate, Ethyl Salicylate, Methyl Benzoate, Ethyl Benzoate, Butyl Benzoate, Diethyl Sebacate, Dibutyl Sebacate, Dioctyl Sebacate, Tricitrate One or a combination of ethyl ester and benzyl ben...

Embodiment 1

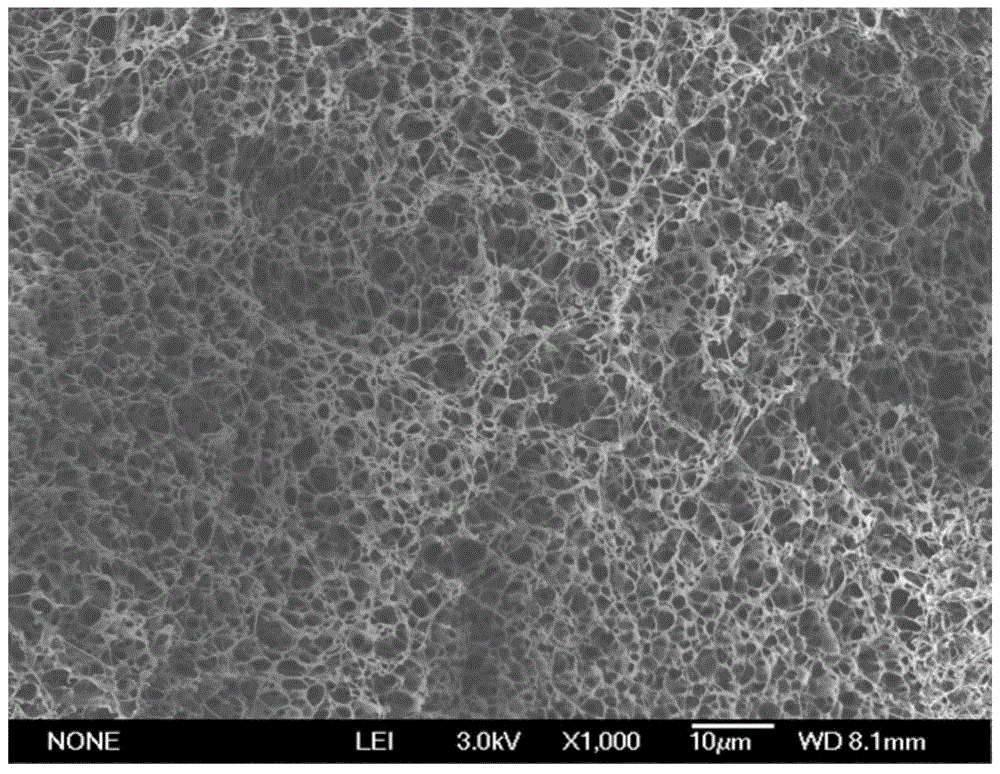

[0034] Polypropylene (weight-average molecular weight is 1000,000, isotacticity is 96%) and tributyl phosphate, the composition of which is 20% by mass of polypropylene and 80% by mass of tributyl phosphate, is added to the same direction Dissolving and defoaming in a twin-screw extruder (screw diameter 20 mm, screw length-to-diameter ratio L / D=60) to obtain a homogeneous casting solution. The polymer homogeneous casting solution is injected into the outer gel medium through the hollow fiber spinneret through the melt pump and the inner gel medium at the same time to solidify to obtain as-spun filaments. Ethanol is used to remove the diluent in the as-spun silk to obtain a polypropylene hollow fiber porous membrane. The detailed preparation parameters and properties of the obtained polypropylene hollow fiber porous membrane are shown in Table 1.

Embodiment 2

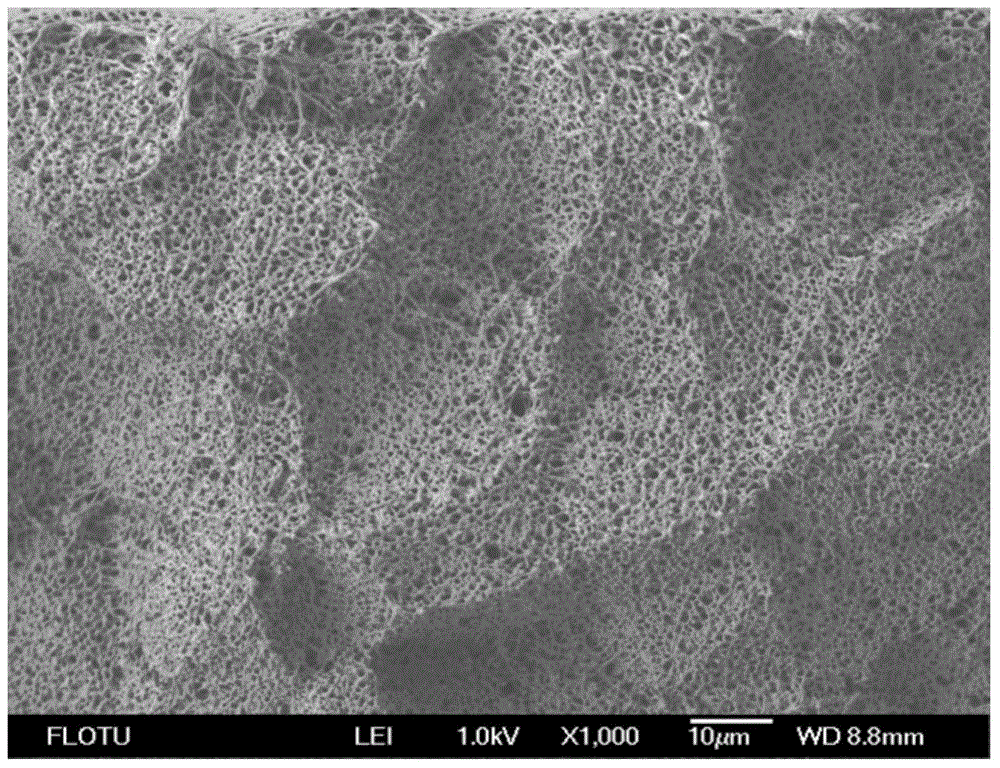

[0036]Polypropylene (weight-average molecular weight is 3000,000, isotacticity is 97%) and triethyl phosphate and trioctyl phosphate, the composition of which is 20% by mass of polypropylene and 40% by mass of triethyl phosphate %, the mass percentage of trioctyl phosphate is 40%, and it is added into a co-rotating twin-screw extruder (screw diameter 20mm, L / D=60) for dissolving and defoaming to obtain a homogeneous casting solution. The polymer homogeneous casting solution is injected into the outer gel medium through the hollow fiber spinneret through the melt pump and the inner gel medium at the same time to solidify to obtain as-spun filaments. Use n-hexane to remove the diluent in the as-spun silk to obtain a polypropylene hollow fiber porous membrane. The detailed preparation parameters and properties of the obtained polypropylene hollow fiber porous membrane are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com