A foam gel preparation device for mine fire prevention

A foam gel and preparation device technology, applied in safety devices, mining equipment, fire prevention, etc., can solve problems such as poor fluidity, poor foam stability, and small diffusion range, and achieve long-term heat absorption resistance and long-term cooling coverage , Improve the effect of diffusion range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

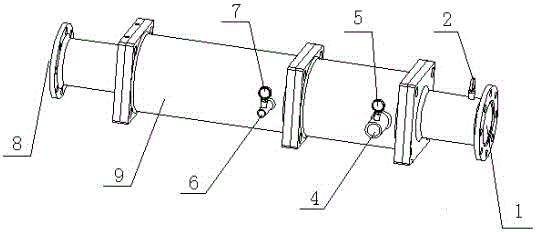

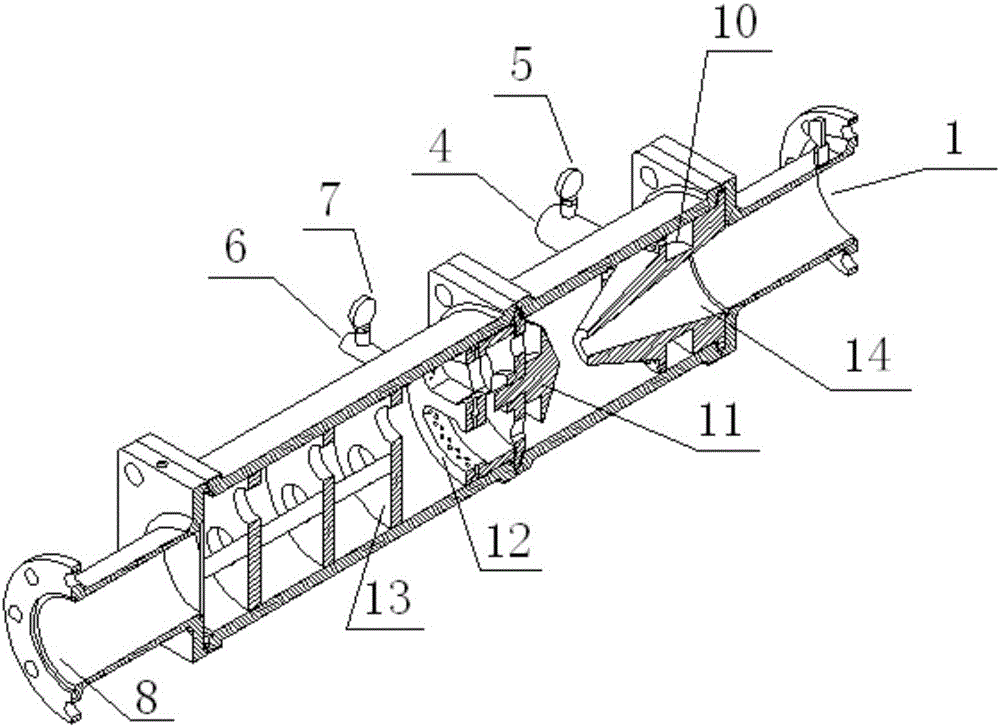

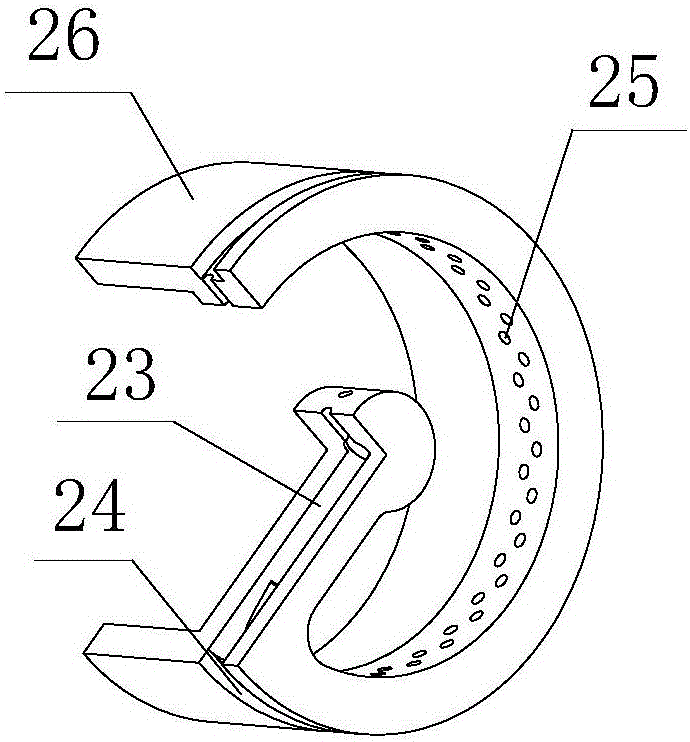

[0019] Such as figure 1 , figure 2 and image 3 As shown, the present invention is used for the foam gel preparation device of mine fire prevention and extinguishing, comprises shell 9, is arranged on the liquid inlet 1 and foam gel outlet 8 of shell 9 two ends, is located at the foaming device in shell 9 , the air intake pipe 4 that is arranged on the outer wall of the housing 9 and communicates with the foaming device; also includes a gelling agent feed pipe 6 and a gelling agent additive 12; the gelling agent additive 12 is mainly composed of a circumferential feeding groove 24, The discharge hole 25 is composed of a positioning cylinder 26. The positioning cylinder 26 is fixed on the inner wall of the housing 9 and is located behind the foaming device. The inner ring of the positioning cylinder 26 forms a circumferential feeding groove 24 which communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com