A method for large-scale clean preparation of graphene

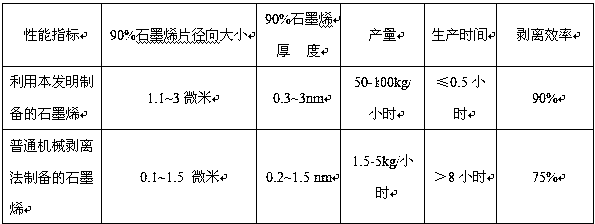

A technology of graphene and graphite, which is applied in the field of large-scale clean preparation of graphene, can solve the problems of destroying the integrity of graphene lattice, reducing the conductivity of the system, and endangering human health, so as to increase the effect of intercalation and improve the efficiency of intercalation probability, the effect of ensuring physical health and life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) 10 parts by weight of flake graphite with an average particle size of less than 1 mm, 50 parts by weight of water, 1.5 parts by weight of sodium carbonate, and 1.5 parts by weight of sodium lauryl sulfate are prepared into a dispersion suspension, and stirred at a speed of 300 rpm Disperse for 10 minutes until the graphite raw material is uniformly dispersed in the solvent to obtain a dispersion suspension.

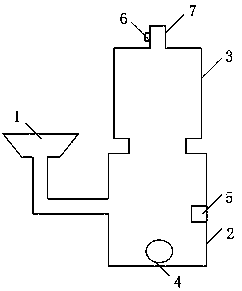

[0032] (2) Put the dispersed suspension solution obtained in step (1) into the feed port of the spray device, the feed port is connected to the feeding chamber, and an ultrasonic probe is set inside the feeding chamber, and the ultrasonic power is set to 100KW. After the dispersed suspension solution enters the material delivery chamber from the feed port, the dispersed suspension solution is ultrasonically treated to allow the foaming agent to enter the graphite interlayer to reduce the graphite interlayer force. Compressor, set the air flow rate in the air co...

Embodiment 2

[0036] (1) 25 parts by weight of flake graphite with an average particle size of less than 1 mm, 60 parts by weight of water, 10 parts by weight of sodium carbonate, and 5 parts by weight of sodium lauryl sulfate are prepared into a dispersion suspension, and stirred at a speed of 400 rpm Disperse for 10 minutes until the graphite raw material is uniformly dispersed in the solvent to obtain a dispersion suspension.

[0037] (2) Put the dispersed suspension solution obtained in step (1) into the feed port of the spray device, the feed port is connected to the feeding chamber, and an ultrasonic probe is set inside the feeding chamber, and the ultrasonic power is set to 100KW. After the dispersed suspension solution enters the material delivery chamber from the feed port, the dispersed suspension solution is ultrasonically treated to allow the foaming agent to enter the graphite interlayer to reduce the graphite interlayer force. Compressor, set the air flow rate in the air compr...

Embodiment 3

[0041] (1) 25 parts by weight of expanded graphite with an average particle size of less than 1 mm, 60 parts by weight of water, 10 parts by weight of a mixture of sodium carbonate and sodium bicarbonate, and 5 parts by weight of sodium dodecylbenzenesulfonate are prepared into a dispersed suspension liquid, stirred and dispersed at 400rpm for 15 minutes, until the expanded graphite was uniformly dispersed in the solvent, and a dispersion suspension was obtained.

[0042] (2) Add the dispersed suspension solution obtained in step (1) into the feed port of the spray device, the feed port is connected to the feeding chamber, and two ultrasonic probes are installed inside the feeding chamber, and the ultrasonic power is set to 200KW. After the dispersed suspension solution enters the material delivery chamber from the feed port, the dispersed suspension solution is ultrasonically treated to allow the foaming agent to enter between graphite layers to reduce the force between graphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com