Organic resistive random access memory and preparation method thereof

A resistive memory, organic technology, applied in the field of memory, can solve problems such as poor chemical stability and thermal stability, and achieve the effects of excellent mechanical properties, good thermal stability, and stable resistive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

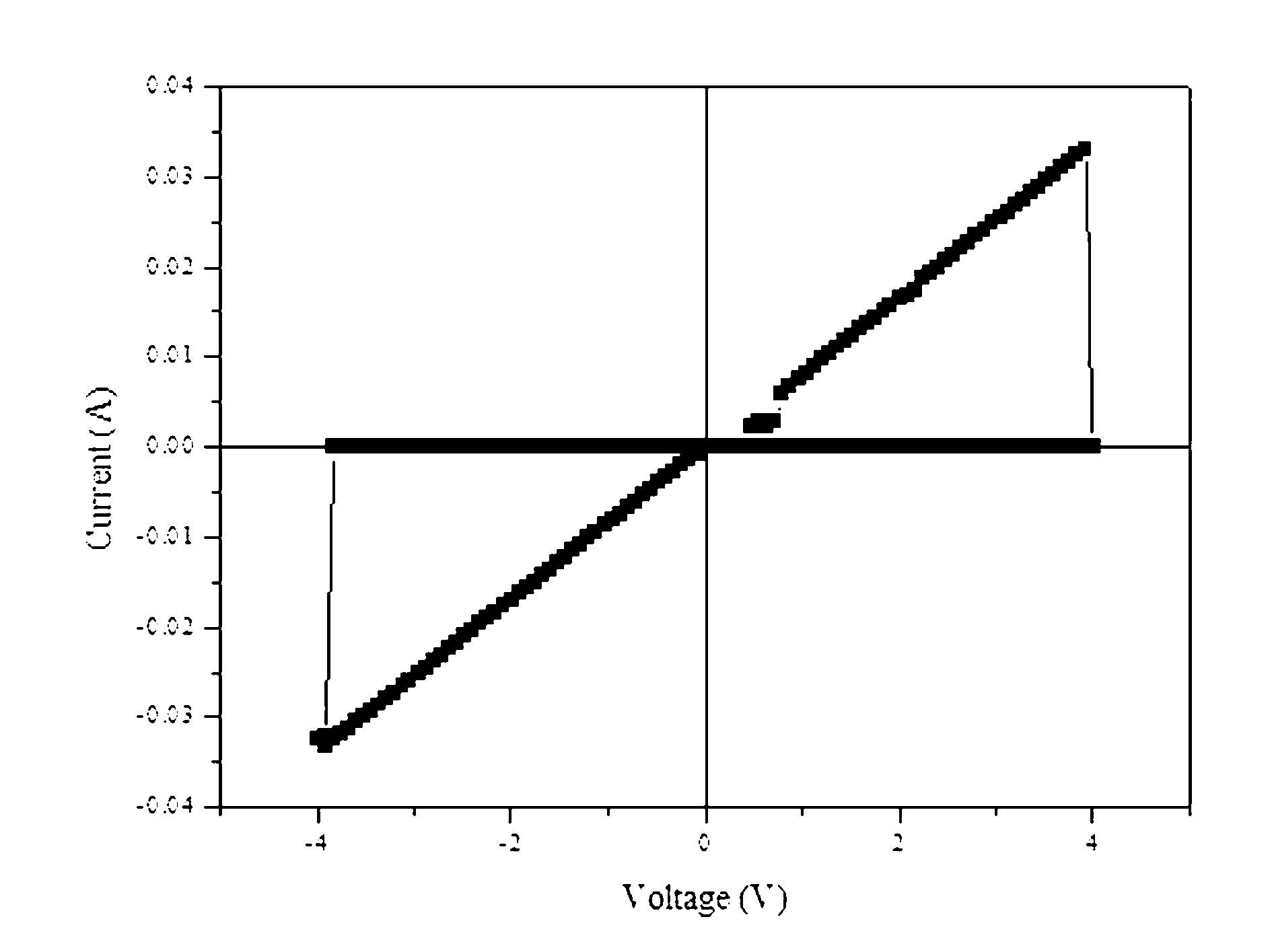

Embodiment 1

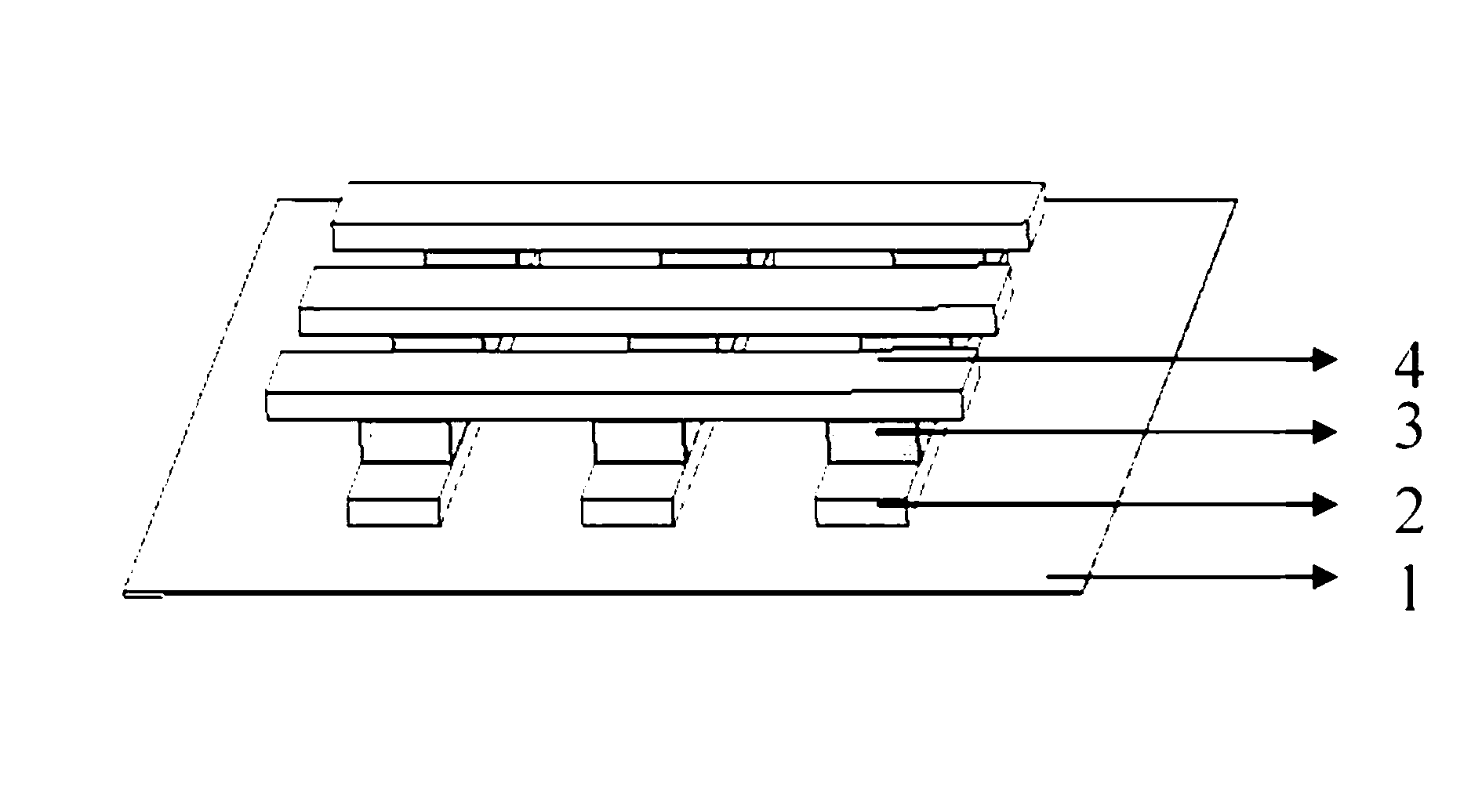

[0032] use figure 1 The array memory structure shown is used to prepare an organic resistive variable memory, which includes a substrate material 1 , a lower electrode 2 , an organic resistive variable layer 3 and an upper electrode 4 from bottom to top.

[0033] Its preparation method is:

[0034] (1) Use glass as the substrate, ultrasonically clean it with deionized water, acetone and alcohol, and dry it with hot air for later use;

[0035] (2) The substrate is prepared with a strip-shaped metal Al lower electrode by evaporation process, with a line width of 80 μm and a thickness of 150 nm;

[0036] (3) Preparation of organic resistive layer:

[0037] Dissolve PEI in chloroform, then drop the PEI solution into MMA, and stir evenly, add 1wt% initiator BPO (benzoyl peroxide) or AIBN (azobisisobutyronitrile), heat up to 75 Stir at ~85°C for 3 hours, then raise the temperature to 125°C and stir for 30 minutes to obtain a blend solution of PMMA prepolymer and PEI, add chloro...

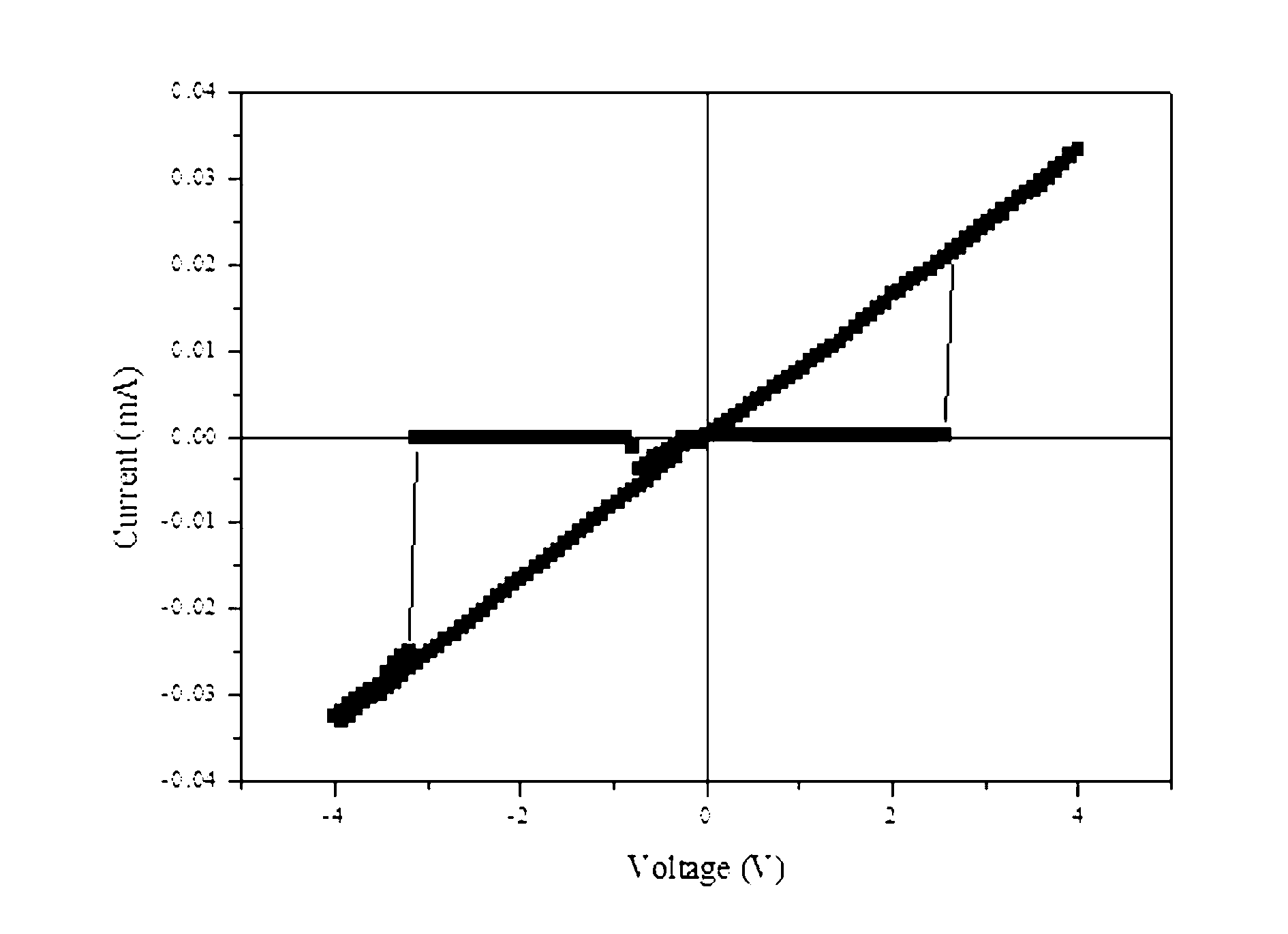

Embodiment 2

[0042] use figure 1 In the array storage structure shown, the strip-shaped metal Ag lower electrode is prepared by evaporation process on the glass substrate, with a line width of 80 μm and a thickness of 80 nm. Dissolve PEI in chloroform, then drop PEI solution into MMA, and stir evenly, add 1wt% initiator BPO (benzoyl peroxide) or AIBN (azobisisobutyronitrile), heat up to 75 Stir at ~85°C for 3 hours, then raise the temperature to 125°C and stir for 30 minutes to obtain a blend solution of PMMA prepolymer and PEI, add chloroform for dilution, and synthesize a molecular level blend. The above solution was spin-coated and deposited on the bottom electrode prepared with the bottom electrode, and then placed in a vacuum oven at 120° C. for curing reaction for 20 minutes to form an organic resistive film with a thickness of about 140 nm. Finally, strip-shaped metal Ag was evaporated on the surface of the organic film superior The electrode has a line width of 80 μm and a thi...

Embodiment 3

[0045] Use PET as the substrate, ultrasonically clean with deionized water, dry with hot air, and then treat the surface with ultraviolet ozone. The substrate is prepared with a strip-shaped metal Ag lower electrode by an evaporation process, with a line width of 80 μm and a thickness of 80 nm. Dissolve PEI in chloroform, then drop the PEI solution into MMA, and stir evenly, add 1wt% initiator BPO (benzoyl peroxide) or AIBN (azobisisobutyronitrile), heat up to 75 Stir at ~85°C for 3 hours, then raise the temperature to 125°C and stir for 30 minutes to obtain a blend solution of PMMA prepolymer and PEI, add chloroform for dilution, and synthesize a molecular level blend. The above solution was spin-coated and deposited on the bottom electrode prepared with the bottom electrode, and then placed in a vacuum oven at 120° C. for curing reaction for 20 minutes to form an organic resistive film with a thickness of about 140 nm. Finally, strip-shaped metal Al is evaporated on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com