Preparation method of glass immobilized enzyme with biological activity

A technology of bioactive glass and immobilized enzymes, applied in the direction of fixing on or in inorganic carriers, fixing on/in organic carriers, etc., can solve the problem that the carrier structure is difficult to control, affects catalytic performance and application, and enzyme activity and the reduction of enzyme catalytic efficiency, to avoid product pollution and side effects, improve the immobilization performance of loaded enzymes, and prevent the leakage of enzyme molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 3g of Lactobacillus salivarius and dissolve it in 80ml of MRS medium solution, cultivate and emulsify it for 17 hours under the conditions of 42°C and pH value of 6, and the cell concentration in the control solution is 7.9×10 6 unit / ml, it is emulsion A.

[0031] 50mol SiO in molar ratio 2 -4mol P 2 o 5 -31mol CaO-15mol ZnO bioactive glass composition, the precursor raw materials ethyl orthosilicate 11.2ml, triethyl phosphate 1.36ml, calcium nitrate tetrahydrate 7.32g, zinc nitrate hexahydrate 4.46g were added to emulsification In solution A, stir for 30 minutes between each addition of a raw material to form precursor sol solution B.

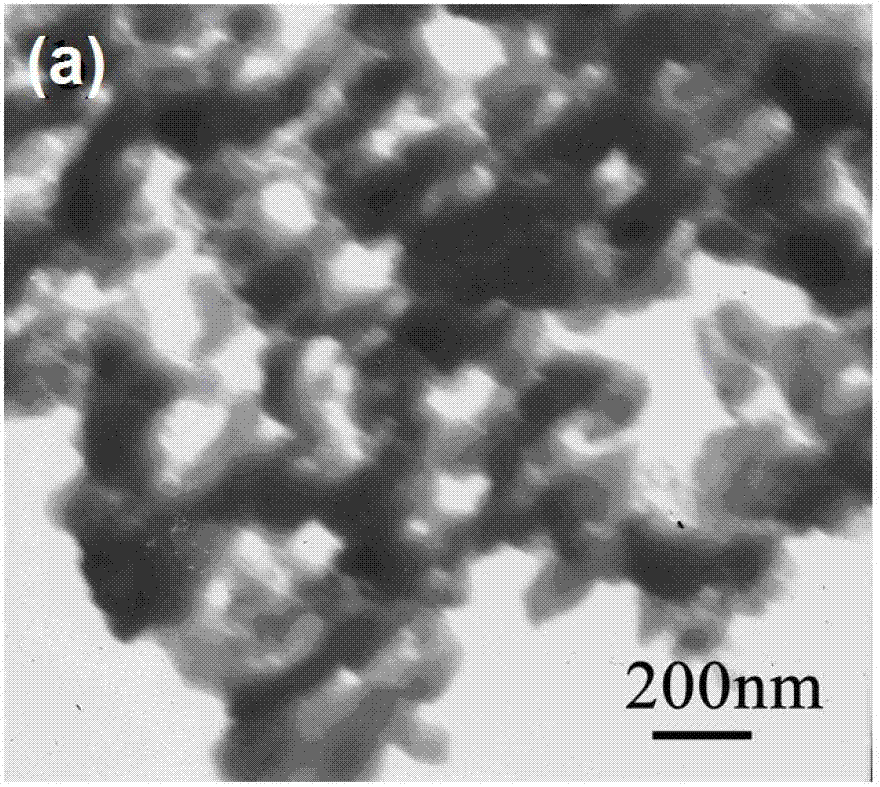

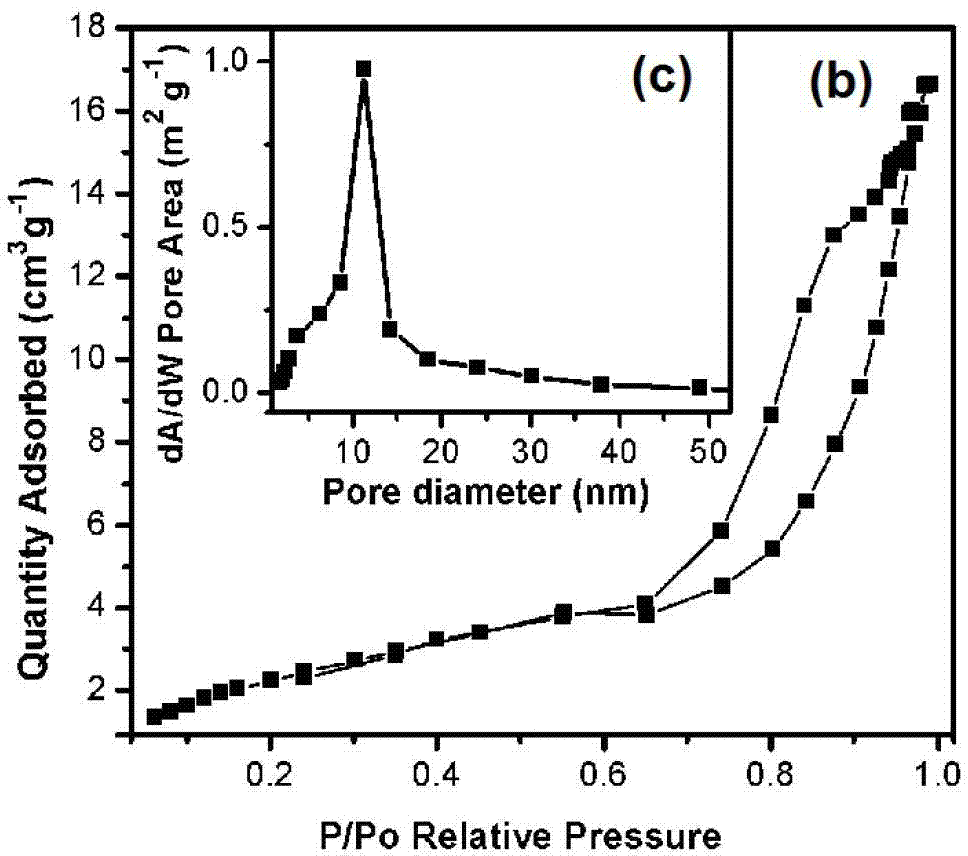

[0032] Put the precursor sol solution B in a sealed container for hydrothermal aging at 70oC for 48h to obtain a wet gel, then dry it at 80°C for 18h to obtain a dry gel; grind it and heat-treat it at 700oC for 3h to obtain a bioactive glass carrier Material, white powder; the material has a porous structure with a macropore diam...

Embodiment 2

[0034] Take 1 g of Lactobacillus salivarius and dissolve it in 50 ml of MRS medium solution, culture and emulsify it for 12 hours under the conditions of 32°C and pH value of 7, and control the cell concentration in the solution to be 7.0×10 6 unit / ml, it is emulsion A.

[0035] 50mol SiO in molar ratio 2 -4mol P 2 o 5 -31mol CaO-15mol ZnO bioactive glass composition, the precursor raw materials ethyl orthosilicate 11.2ml, triethyl phosphate 1.36ml, calcium nitrate tetrahydrate 7.32g, zinc nitrate hexahydrate 4.46g were added to emulsification In solution A, stir for 30 minutes between each addition of a raw material to form precursor sol solution B.

[0036] Put the precursor sol solution B in a sealed container and age at 60oC for 72h to obtain a wet gel, then dry it at 60oC for 24h to obtain a dry gel; grind it and heat-treat it at 600oC for 5h to obtain a white bioactive glass Powder; the powder has a porous structure with a macropore diameter of 80-150 nm and a mesopo...

Embodiment 3

[0038] Take 5 g of Lactobacillus salivarius and dissolve it in 100 ml of MRS medium solution, cultivate and emulsify it for 24 hours under the conditions of 58° C. and pH value of 4, and control the cell concentration in the solution to be 10.0×10 6 unit / ml, it is emulsion A.

[0039] 50mol SiO in molar ratio 2 -4mol P 2 o 5 -31mol CaO-15mol ZnO bioactive glass composition, the precursor raw materials ethyl orthosilicate 11.2ml, triethyl phosphate 1.36ml, calcium nitrate tetrahydrate 7.32g, zinc nitrate hexahydrate 4.46g were added to emulsification In solution A, stir for 30 minutes between each addition of a raw material to form precursor sol solution B.

[0040] Put the precursor sol solution B in a sealed container and age at 80oC for 12h to obtain a wet gel, then dry it at 100oC for 12h to obtain a dry gel; grind it and heat-treat it at 800oC for 2h to obtain a white bioactive glass Powder; the powder has a porous structure, the diameter of the macropore is 120-240nm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mesopore | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com