Molybdenum copper alloy foil sheet and preparation method thereof

A technology of molybdenum-copper alloy and foil, which is applied in the field of molybdenum-copper alloy foil and its preparation, can solve the problems of poor processing performance and low density of molybdenum-copper alloy, and achieve reduced rolling process, high density, and reduced production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

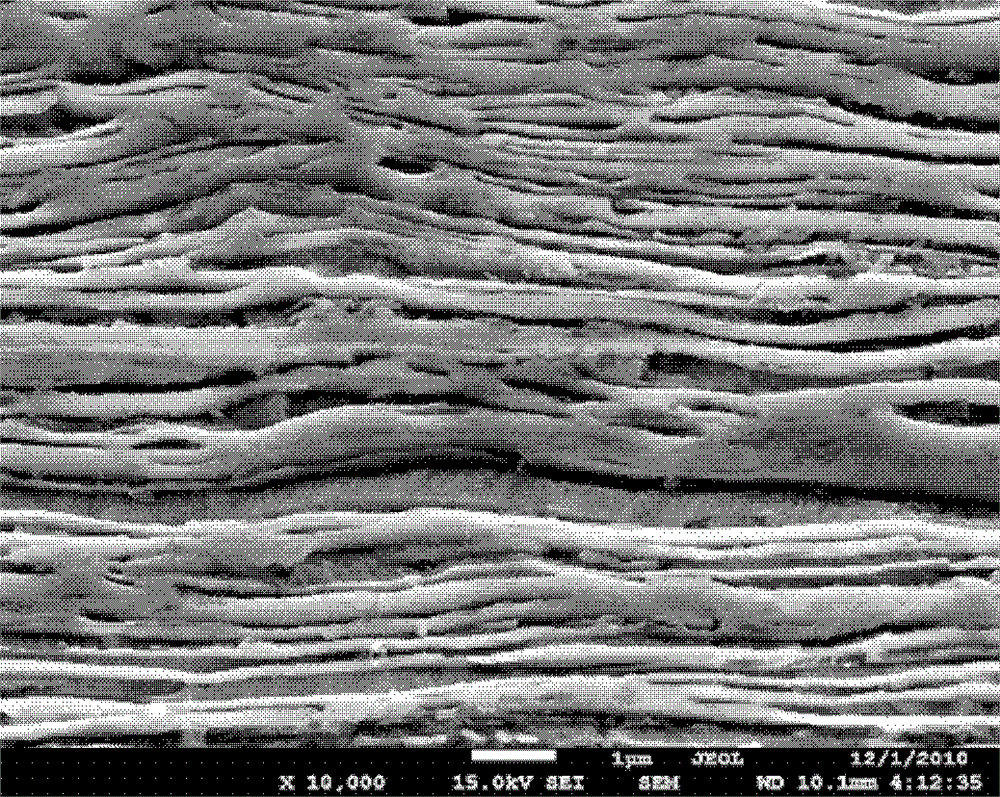

Image

Examples

preparation example Construction

[0026] The preparation method of the molybdenum-copper alloy foil whose copper mass percentage is 20-50% and the balance is molybdenum of the present invention comprises the following steps in sequence:

[0027] 1) Take copper powder accounting for 1 / 4 to 2 / 5 of the design content weight, such as copper powder with a mass percentage of 5% to 20%, and molybdenum powder with the same mass percentage as the molybdenum-copper alloy foil design content, The method of high-energy ball milling is used for mixing; the inner wall of the material tank, the grinding ball and the stirring rod of the high-energy ball mill are all made of dispersion-strengthened copper materials; the time of high-energy ball milling is 8 to 14 hours, and argon gas is introduced during the ball milling process. The internal pressure is maintained at 0.2-0.3MPa.

[0028] 2) Molding the ball-milled powder into a slab with a thickness of 10-14 mm to obtain a molybdenum-copper alloy compact.

[0029] 3) Pre-sin...

Embodiment 1

[0033] A molybdenum-copper alloy foil with a thickness of 0.1-1.0mm, the molybdenum-copper alloy foil includes the following components and content (weight): 80% molybdenum and 20% copper. Its preparation process comprises the following steps:

[0034] 1) Take the copper powder with a mass percentage of 7%, and the molybdenum powder with the same mass percentage (80%) as the molybdenum-copper alloy foil, and mix them for 14 hours by high-energy ball milling; the high-energy ball mill adopts the inner wall of the material tank, Both the grinding ball and the stirring rod are made of dispersion-strengthened copper; argon gas is introduced during the ball milling process, and the pressure in the ball mill tank is maintained at 0.2MPa;

[0035] 2) molding the powder after ball milling into a slab with a thickness of 12 mm to obtain a molybdenum-copper alloy compact;

[0036] 3) Place the compact in a hydrogen furnace for pre-sintering at a sintering temperature of 900°C and keep ...

Embodiment 2

[0041] A molybdenum-copper alloy foil with a thickness of 0.1-1.0mm, the molybdenum-copper alloy foil includes the following components and contents (weight): 70% molybdenum and 30% copper. Its preparation process comprises the following steps:

[0042] 1) Take copper powder with a mass percentage of 10%, and molybdenum powder with the same mass percentage as the molybdenum-copper alloy foil, and mix them for 10 hours by means of high-energy ball milling; The rods are all made of dispersion-strengthened copper; argon gas is introduced during the ball milling process, and the pressure in the ball mill tank is kept at 0.3MPa;

[0043] 2) molding the powder after ball milling into a slab with a thickness of 10 mm to obtain a molybdenum-copper alloy compact;

[0044] 3) Pre-sintering the green compact in a hydrogen furnace at a sintering temperature of 800°C for 1 hour;

[0045] 4) According to the composition ratio of the molybdenum-copper alloy foil, the additional 20% copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com