Composite dipping glue used for preparing high temperature filter material and usage method

A technology of impregnating glue and filter material, which is applied in the field of compound impregnating glue for preparing high-temperature filter material, which can solve the problems of glass fiber surface smoothness, poor moisture resistance, damage to the reasonable microstructure of filter material, and reduced air permeability of filter bags. Achieve the effects of wide adjustment of dilution factor, easy dispersion, and smoothness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

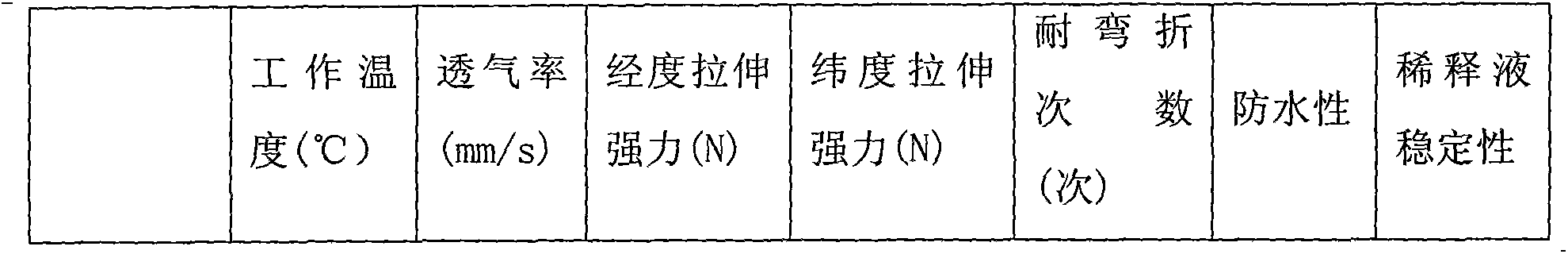

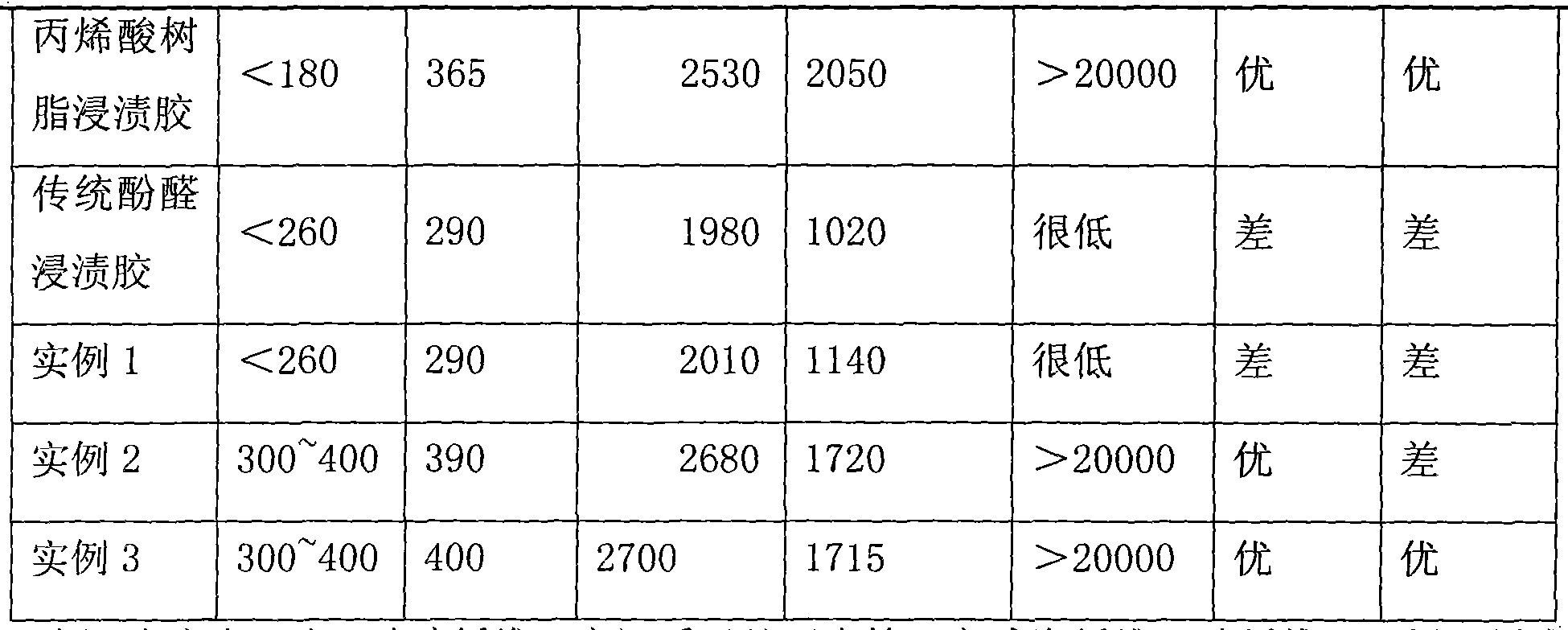

Examples

Embodiment 1

[0074] Prepare 100kg of diluent for processing high-temperature filter material: add 2kg of component A (2% by weight), 94kg of water (94% by weight), and 4kg of component B (4% by weight). Wherein component A includes 15 parts by weight of phenolic resin, 36 parts by weight of water, and 49 parts by weight of cosolvent; component B includes 83 parts by weight of water, 9 parts by weight of catalyst, 4 parts by weight of chelating agent and carbonizing agent , 4 parts by weight of flame suppressant.

[0075] The method of use is:

[0076] 1 with glue:

[0077] Add A and B component glue and water into the reaction kettle in proportion, and stir evenly;

[0078] 2 dipping:

[0079] Pour the evenly stirred impregnating glue into the impregnating tank, and the fiber needled felt enters the impregnating pool to impregnate under the drive of the roller. Ensure the continuation of the dipping process;

[0080] 3 flatness treatment:

[0081] The surface of the fiber needle-punc...

Embodiment 2

[0092]Prepare 100kg of diluent for processing high-temperature filter material: add 2kg of component A (2% by weight), 94kg of water (94% by weight), and 4kg of component B (4% by weight). Wherein A component comprises the phenolic resin of 15 weight parts, the water of 35 weight parts, the toughening agent of 8 weight parts, the cosolvent of 42 weight parts; B component comprises the water of 49 weight parts, the catalyst of 9 weight parts, 13 Parts by weight of inorganic binder, 4 parts by weight of coupling agent, 4 parts by weight of chelating agent and charring agent, 4 parts by weight of flame suppressant, 8 parts by weight of antiwear agent, 9 parts by weight of water and oil repellent .

[0093] Using method is the same as embodiment 1.

[0094] In this example, tougheners, inorganic adhesives, coupling agents, anti-wear agents, and waterproof and oil-repellent agents are added on the basis of the examples. The beads can keep rolling smoothly on the surface of the fi...

Embodiment 3

[0096] Prepare 100kg of diluent for processing high-temperature filter material: add 2kg of component A (2% by weight), 94kg of water (94% by weight), and 4kg of component B (4% by weight). Wherein A component comprises the phenolic resin of 15 parts by weight, the water of 35 parts by weight, the toughening agent of 8 parts by weight, the stabilizer of 5 parts by weight, the cosolvent of 37 parts by weight; B component comprises the water of 49 parts by weight, 9 parts by weight of catalyst, 13 parts by weight of inorganic binder, 4 parts by weight of coupling agent, 4 parts by weight of chelating agent and carbonization agent, 4 parts by weight of flame suppressant, 8 parts by weight of antiwear agent, 9 parts by weight of Water and oil repellent in parts by weight.

[0097] Using method is the same as embodiment 1.

[0098] In this example, a stabilizer is added on the basis of Example 2. The strength of the obtained high-temperature filter material is better, and the numb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com