Brazing filler metal precoating vacuum brazing method for titanium alloy and aluminum alloy

A brazing method and aluminum alloy technology, which are applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult wetting of aluminum-based brazing materials, low joint strength, and cumbersome problems, so as to improve wetting. The effect of spreading ability, low manufacturing cost and simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

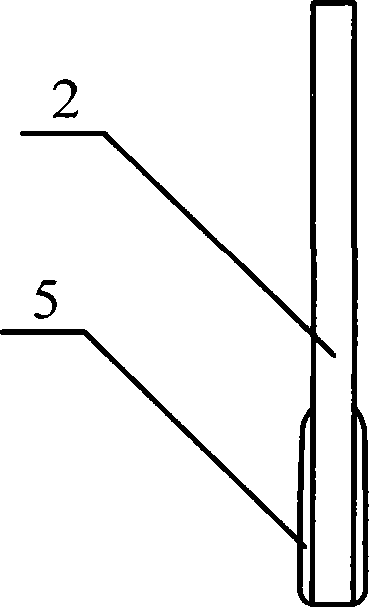

[0027] The invention provides a vacuum brazing method for titanium alloy and aluminum alloy solder pre-coating, such as Figure 1-4 It is the main process diagram; the base material is 50mm×40mm×2mm TC4 titanium alloy plate 2 and pure aluminum plate 8, and the coating material is AlSi12 whose melting point is lower than that of the aluminum base material. During the brazing process, the coating melts and acts as a solder, and is welded with the aluminum plate together. The plating flux 3 is a suspension prepared by dissolving the fluoride flux NOCOLOK in acetone. Apply the flux 3 to the range of 15 mm wide at one end of the titanium alloy plate, and let it dry naturally; cut the cleaned AlSi12 welding wire into small pieces and place Put the graphite crucible 1 into the electric furnace and heat it to 750°C. After the AlSi12 welding wire is completely melted, keep it warm for one hour to homogenize the temperature of the molten aluminum. The end of the titanium plate coated w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com