Steel with multi-scale twin-crystal structure and preparation method of steel

A multi-scale, structural steel technology, applied in the field of crystal structure steel and its preparation, can solve the problems of difficult preparation of fine twins, and achieve the effects of high wear resistance, good thermal stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of AISI 304 stainless steel plate with multi-scale twin structure, the steps are as follows:

[0041] Put the AISI 304 stainless steel plate with a thickness of 1mm into the pretreatment chamber of the high-speed impact equipment, and control the strain rate to 5′10 4 m / s, the impact velocity is 7m / s, and after surface mechanical grinding at room temperature 23 ℃ for 10min, the AISI 304 stainless steel plate with multi-scale twin structure can be obtained.

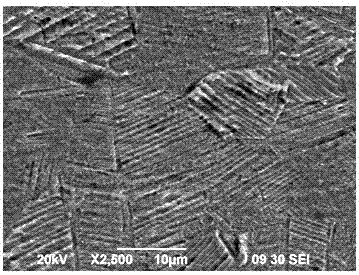

[0042] The AISI 304 stainless steel plate with multi-scale twin structure obtained above was examined by transmission electron microscope (JEM 2010, Japan JEOL Electronics Co., Ltd.), scanning electron microscope (HITACHI S-4200, Japan Hitachi) and X-ray diffraction instrument (Bruker D8, Germany Bruker) conducted observations, and the results showed that its microstructure is nano- and sub-micron scale twins, nanocrystals and a¢martensite;

[0043] The AISI 304 stainless steel plate with multi-scal...

Embodiment 2

[0050] The preparation of AISI 304 stainless steel plate with multi-scale twin structure, the steps are as follows:

[0051] Put the AISI 304 stainless steel plate with a thickness of 1mm into the pretreatment chamber of the high-speed impact equipment, and control the strain rate to 8′10 6 m / s, the impact velocity is 19m / s, and the room temperature is 23°C. After surface mechanical grinding for 20min, the AISI 304 stainless steel plate with multi-scale twin structure is obtained.

[0052] The above-mentioned AISI 304 stainless steel plate with multi-scale twin structure was analyzed by XRD (Bruker D8, Bruker, Germany) instrument, and its surface microstructure was composed of austenite with a volume fraction of 94% and a¢ with a volume fraction of 5%. Composed of martensite and 1% e martensite.

[0053] The above obtained AISI 304 stainless steel plate with multi-scale twin structure was measured by transmission electron microscope (JEM 2010, Japan JEOL Electronics Co., Ltd....

Embodiment 3

[0056] The preparation of AISI 301 stainless steel plate with multi-scale twin structure, the steps are as follows:

[0057] Put the AISI 301 stainless steel plate with a thickness of 1 mm into the pretreatment chamber of the high-speed impact equipment, and control the strain rate to 2′10 2 m / s, the impact velocity is 3m / s, and after cooling with liquid nitrogen at -80°C for 1min, the AISI 301 stainless steel plate with multi-scale twin structure is obtained.

[0058] The AISI 301 stainless steel plate with multi-scale twin structure obtained above was observed by transmission electron microscopy (JEM 2010, JEOL Electronics Co., Ltd., Japan) and XRD (Bruker D8, Bruker, Germany) instruments. Its microstructure is twins, nanocrystals, a¢martensite and e martensite, the volume fraction of a¢martensite is 26%, the volume fraction of e martensite is 8%, and the volume fraction of g austenite is 66%.

[0059] The above-mentioned AISI 301 stainless steel plate with multi-scale twin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com