Vanadate green emitting phosphor as well as preparation method and application thereof

A technology of green phosphor and vanadate, which is applied in the field of ultraviolet-near ultraviolet white light LED, can solve the problems of self-activated vanadate green phosphor, which has not been disclosed, affects the light emission of phosphor, and production restrictions, etc., and achieves high Crystallinity and visible light transmittance, wide application prospects, easy-to-handle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Preparation of Sr 6 V 2 o 11

[0033] According to the chemical formula Sr 6 V 2 o 11 The stoichiometric ratio of each element in SrCO3 was weighed separately 3 : 4.429 g, ammonium metavanadate NH 4 VO 3 : 1.17 g, after grinding and mixing in an agate mortar, select the air atmosphere for the first calcination, the temperature is 400 ° C, the calcination time is 7 hours, then cool to room temperature, take out the sample; the raw material calcined for the first time is fully Mix and grind evenly, sinter again in air atmosphere, temperature 500°C, calcination time 8 hours, then cool to room temperature, take out the sample; finally it is fully ground again and placed in a muffle furnace for air sintering, the calcination temperature is 900°C, The calcining time is 6 hours, and the powdery vanadate green luminescent material is obtained.

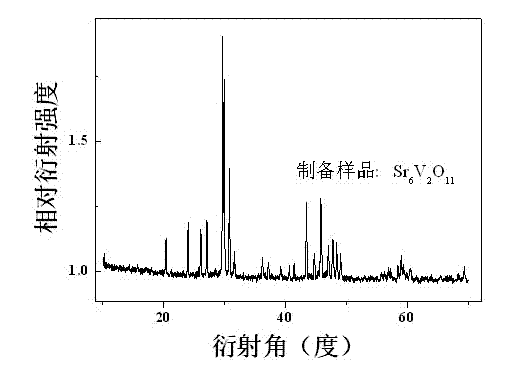

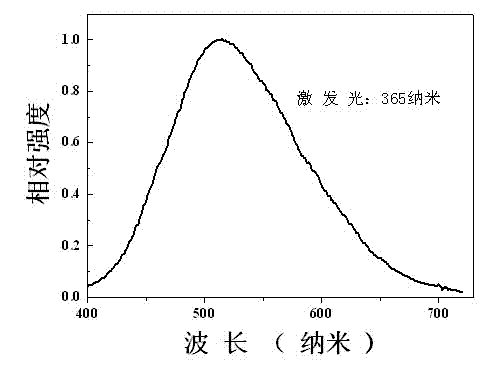

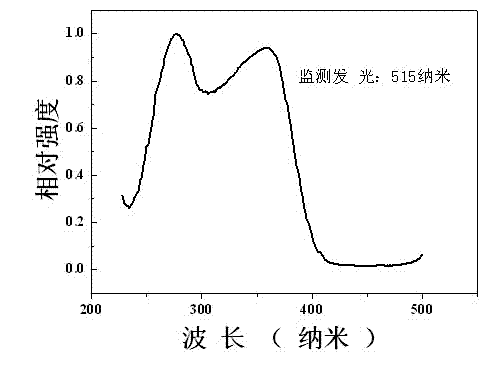

[0034] See attached figure 1 , which is the X-ray powder diffraction pattern of the sample prepared by the technical scheme o...

Embodiment 2

[0039] Preparation of Sr 6 V 2 o 11

[0040] According to the chemical formula Sr 6 V 2 o 11 The stoichiometric ratio of each element in SrCO3 was weighed separately 3 : 4.429 g, vanadium pentoxide V 2 o 5 : 0.910 g, after being ground and mixed in an agate mortar, select the air atmosphere for the first calcination, the temperature is 450 ° C, the calcination time is 3 hours, then cooled to room temperature, and the sample is taken out; the raw material calcined for the first time is fully Mix and grind evenly, sinter again in air atmosphere, temperature 500°C, calcination time 7 hours, then cool to room temperature, take out the sample; finally it is fully ground again and placed in a muffle furnace for air sintering, the calcination temperature is 850°C, The calcining time is 4 hours, and the powdery vanadate green luminescent material is obtained. Its main structural properties, excitation spectrum, luminescence spectrum and decay curve are similar to those of Exa...

Embodiment 3

[0042] Preparation of Sr 6 V 2 o 11

[0043] According to the chemical formula Sr 6 V 2 o 11 The stoichiometric ratio of each element in the weighted strontium oxide SrO: 3.109 grams, vanadium pentoxide V 2 o 5 : 0.910 g, after grinding and mixing in an agate mortar, select the air atmosphere for the first calcination, the temperature is 300 ° C, the calcination time is 8 hours, then cool to room temperature, take out the sample; the raw material for the first calcination is fully Mix and grind evenly, then sinter again in air atmosphere, the temperature is 450°C, the calcination time is 6 hours, then cool to room temperature, take out the sample; finally it is fully ground again and placed in the muffle furnace for air sintering, the calcination temperature is 700°C, The calcining time is 7 hours, and the powdery vanadate green luminescent material is obtained. Its main structural properties, excitation spectrum, luminescence spectrum and decay curve are similar to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com