High-efficiency grey water dispersing agent

A dispersant, grey water technology, applied in descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc. To achieve the effect of reducing equipment maintenance and production costs, good treatment effect, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

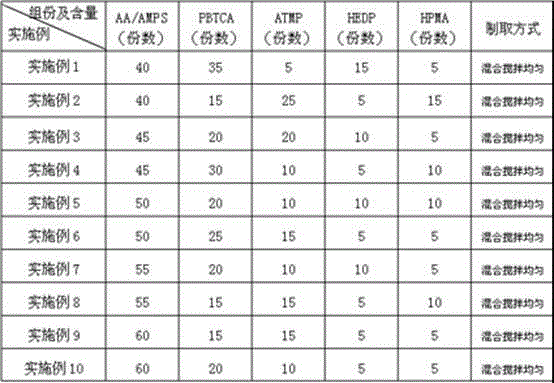

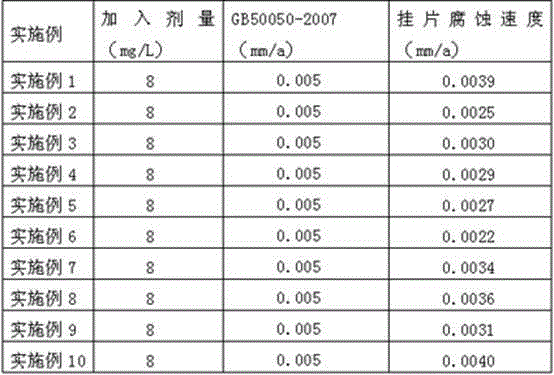

Examples

preparation example Construction

[0041] Preparation of test solution: Add sodium bicarbonate solution (4.7)a with a burette (5.2) 2 mL into a 500mL volumetric flask, transfer 5.00mL water treatment agent sample solution (6.1), add 250mL water, and shake well. Slowly add calcium chloride solution (4.9)a with a burette (5.2) 3 mL, dilute to the mark with water, shake well, and prepare 1L containing 5.00mg of water treatment agent, 240mg (6.00mmol) of calcium ion (Ca 2+ ) and 732mg (12.0mmol) bicarbonate ion (HCO 3 - ) test solution;

[0042] Reagents: ① Potassium hydroxide solution: 200g / L; ② Disodium ethylenediaminetetraacetic acid (EDTA): 0.01mol / L; ③ Hydrochloric acid: 0.1mol / L; ④ Calcein-phenolphthalein mixed indicator: weigh 0.20g Calcein, 0.070g phenolphthalein (GB 10729), put in a glass mortar, add 20g of potassium chloride (GB 646) dried at 120°C, grind and mix well, and store in a brown grinding bottle; Phenol green-methyl red mixed indicator: 3 volumes of 1.00g / L bromocresol green (HG3-1220) etha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com