Alloy powder material for Fe-based nonmagnetic cladding layer and cladding layer preparing method

A technology of alloy powder and cladding layer, applied in metal material coating process, metal processing equipment, welding/cutting medium/material, etc., to achieve the effect of good manufacturability, smooth and uniform surface, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

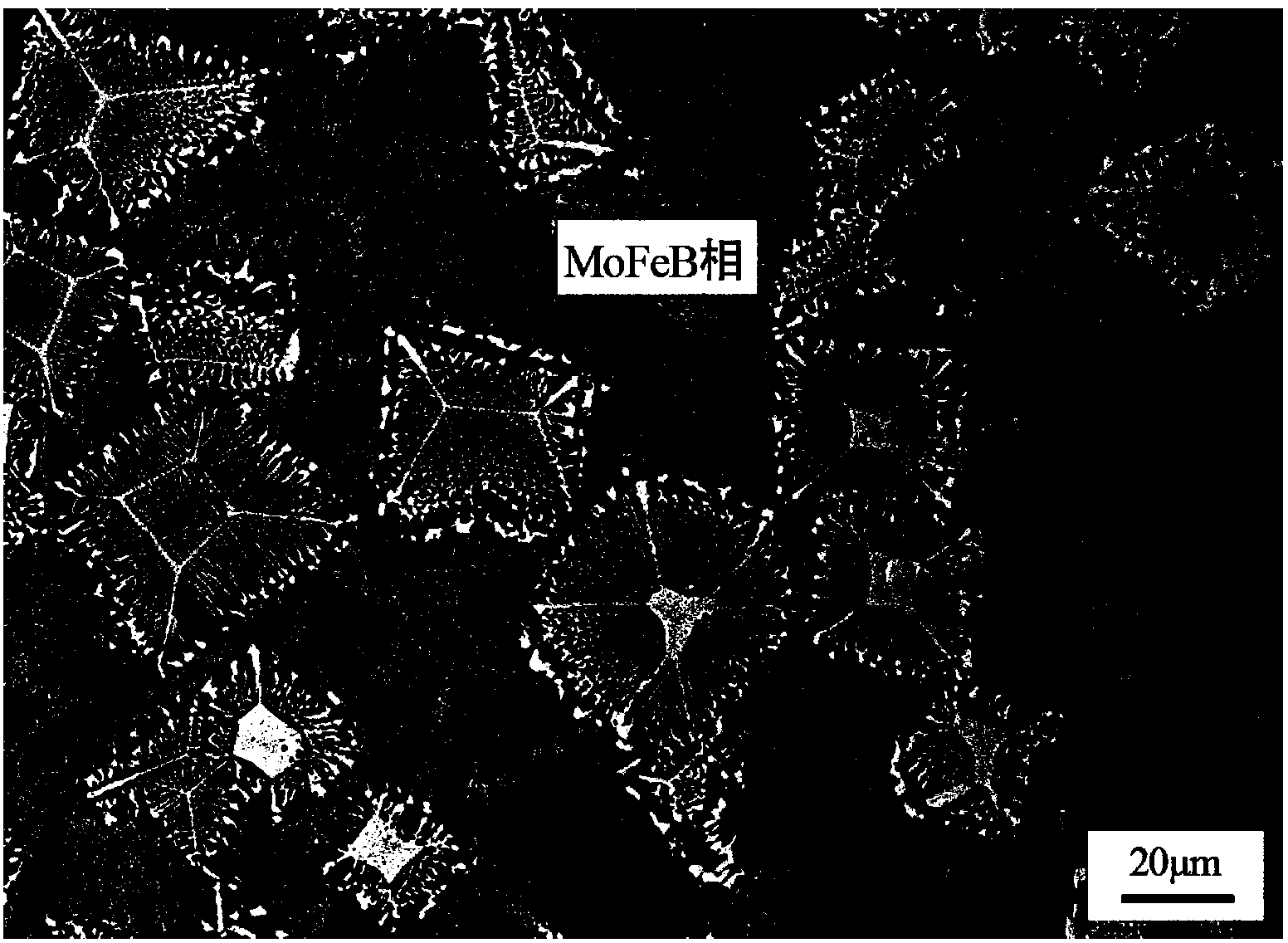

Embodiment 1

[0036] According to the mass percentage of Fe-based multi-component alloy powder elements: Cr: 9wt.%; Mo: 19wt%; C: 2.0wt.%; B: 1.5wt.%; Si: 1wt.%; :margin. Plasma arc surfacing parameters used to prepare cladding layer: transferred arc voltage 29-31V; transferred arc current 90A; spraying distance 13mm; ion gas (Ar): 4-4.5L / h; powder feeding gas (Ar): 4-4.5 L / h; protective gas (Ar): 6.5-7L / h; powder feeding voltage: 6.3V.

Embodiment 2

[0038] According to the mass percentage of Fe-based multi-element alloy powder: Cr: 11wt.%; Mo: 21wt%; C: 2.3wt.%; B: 1.8wt.%; Si: 0.8wt.%; Fe: margin. Plasma arc surfacing parameters used to prepare cladding layer: transferred arc voltage 29-31V; transferred arc current 90A; spraying distance 13mm; ion gas (Ar): 4-4.5L / h; powder feeding gas (Ar): 4-4.5 L / h; protective gas (Ar): 6.5-7L / h; powder feeding voltage: 6.3V.

Embodiment 3

[0040]According to the mass percentage of Fe-based multi-element alloy powder: Cr: 13wt.%; Mo: 23wt%; C: 2.5wt.%; B: 2.0wt.%; Si: 0.5wt.%; Fe: margin. Plasma arc surfacing welding parameters used to prepare cladding layer: transferred arc voltage 29-31V; transferred arc current 90A; spraying distance 13mm; ion gas (Ar): 4-4.5L / h; powder feeding gas (Ar): 4-4.5 L / h; protective gas (Ar): 6.5-7L / h; powder feeding voltage: 6.3V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com