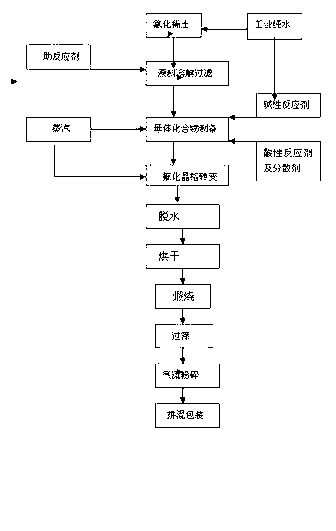

Production process of nano spherical grape-shaped lanthanum oxide cerium rare earth polishing powder

A rare earth polishing powder, lanthanum cerium oxide technology, applied in the directions of nanotechnology, nanotechnology, rare earth metal compounds, etc., can solve the problems of irregular appearance and shape of lanthanum cerium oxide rare earth polishing powder, decreased precision, irregular product surface, etc. To achieve the effect of not easy to deep scratch, improve surface accuracy, high surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Industrial pure water dissolves the rare earth chloride raw material and the reactant ammonium bicarbonate separately, and adds an acid co-reactant (such as: hydrochloric acid, silicic acid, sulfuric acid, etc.) to control the pH value of 3.5-4; When the alkaline reactant ammonium bicarbonate is processed, the concentration of the alkaline reactant is controlled at 10%-35%. The concentration of the dissolved rare earth raw material REO (total amount of rare earth) is controlled at 120-160 g / L, filtered, and added to the parent compound preparation device ∮ 2000-8.5, heated and stirred with steam, and the temperature is controlled between 30°C-60°C , add hydrofluoric acid, when the amount of hydrofluoric acid in the parent compound preparation device ∮ 2000-8.5 reaches 6.5-8% of the total amount of REO in the preparation device, the hydrofluoric acid injection is completed; to the parent compound preparation device Add dispersant and ammonium bicarbonate, control the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com