Electrode layout method of static formed film antenna

An electrostatic forming and layout method technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as no positive solutions, and achieve the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

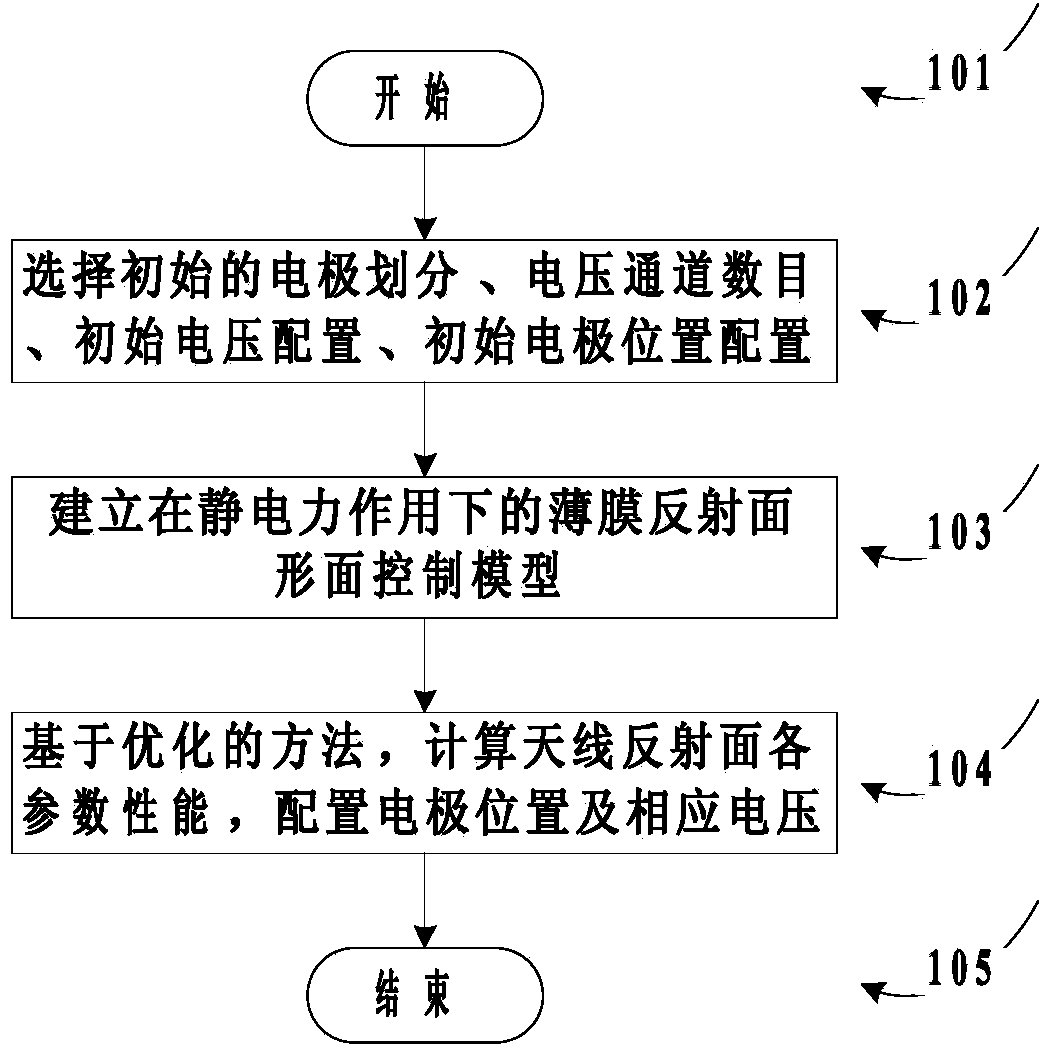

[0042] like figure 1 Shown, a kind of electrode layout method of electrostatic forming film antenna, it is characterized in that: comprise the steps:

[0043] Step 101: Start the electrostatic forming film reflector antenna electrode layout method;

[0044] Step 102: Select initial electrode division, number of voltage channels, initial voltage configuration, and initial electrode position configuration;

[0045] Step 103: Establishing a shape control model of the thin film reflective surface under the action of electrostatic force;

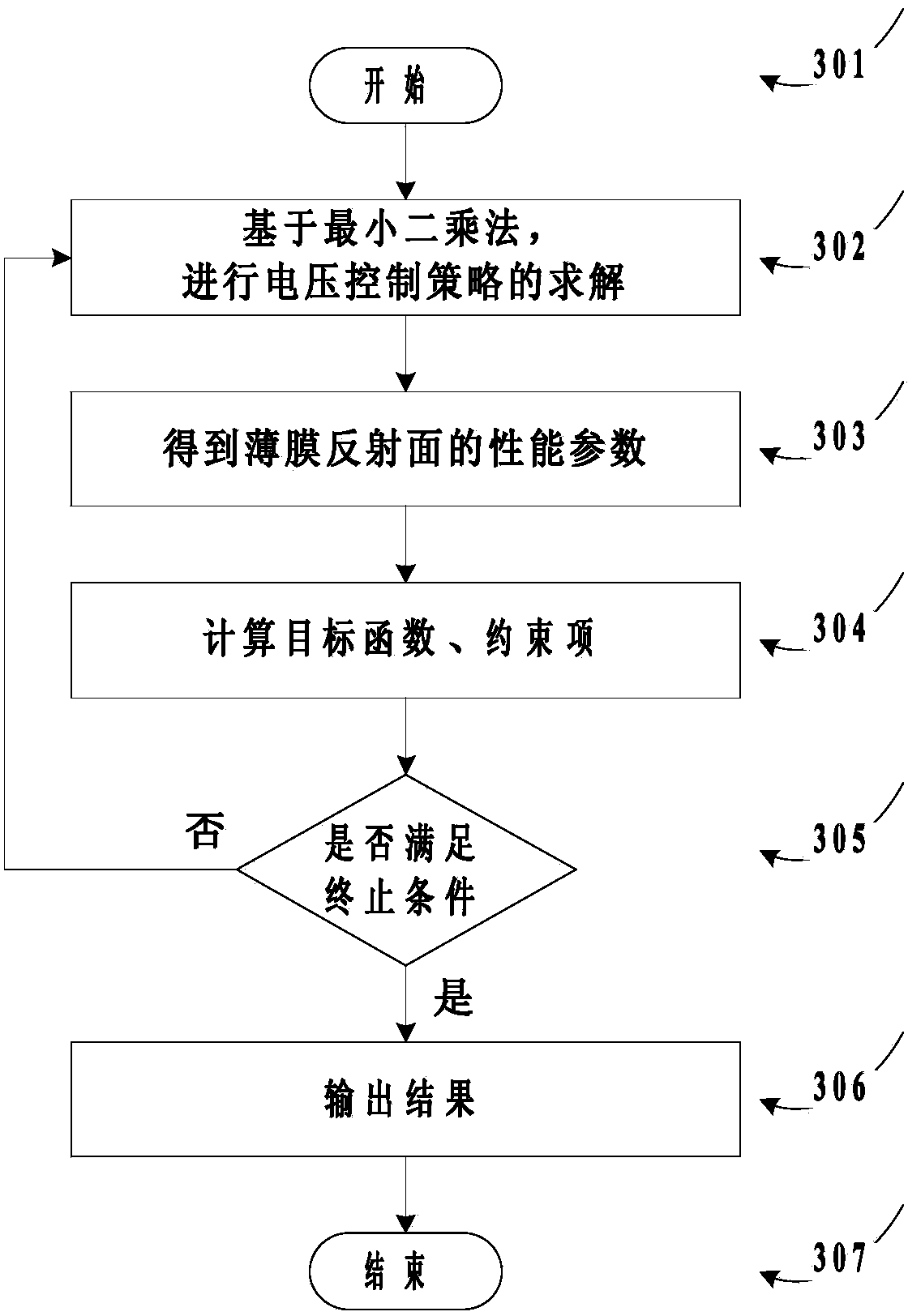

[0046] Step 104: Based on the optimization method, calculate the performance of each parameter of the antenna reflector, configure the electrode position and the corresponding voltage;

[0047] Step 105: End the antenna layout method of the electrostatically formed film reflector.

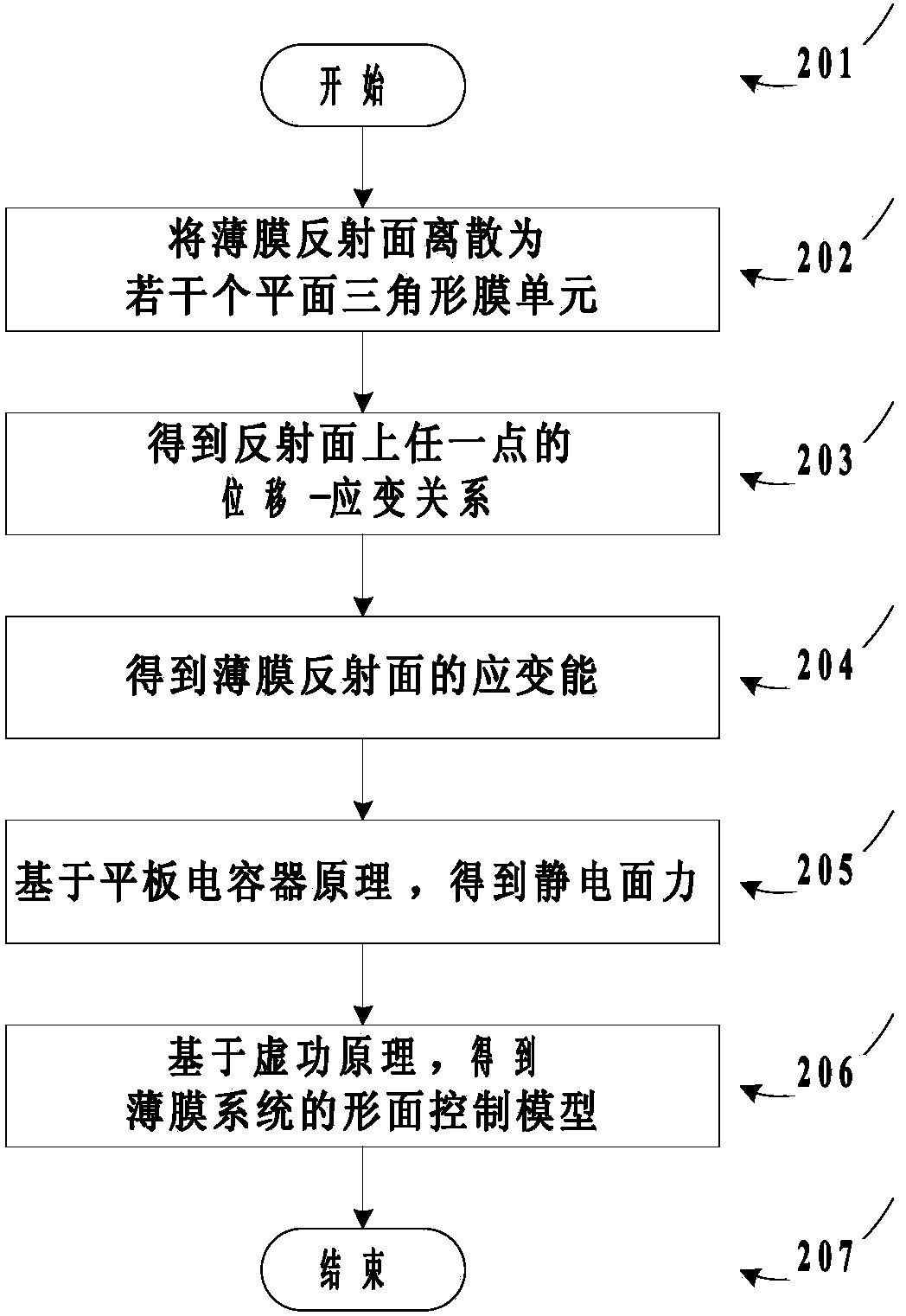

[0048] like figure 2 As shown, the described step 103 establishes the thin film reflective surface shape control model under the action of electrostatic force an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com