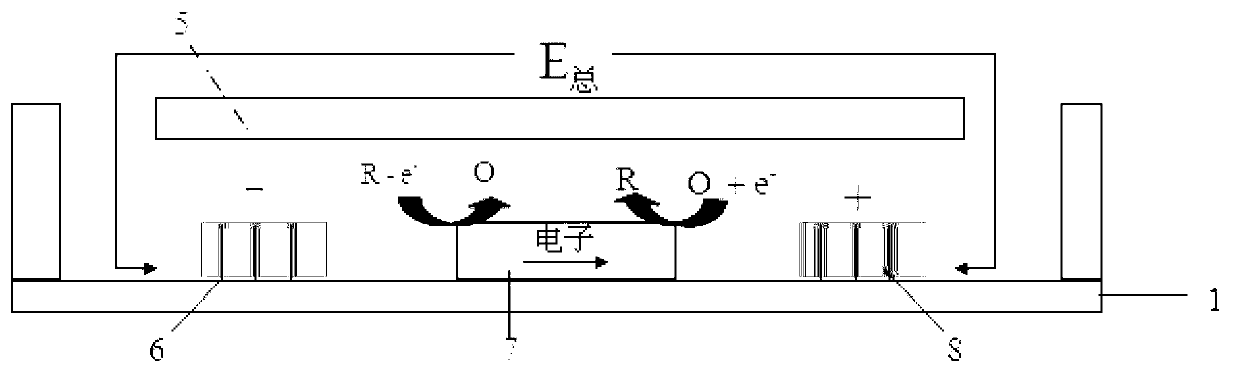

Bipolar electrode-paper-based microfluidics type chip and preparation method thereof

A microfluidic chip and bipolar electrode technology are applied in the field of microfluidic analysis to achieve the effects of low cost, fast analysis speed and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A. Paper-based cover sheet production

[0039] according to figure 1 (B) Dilute the photoresist SU-82025 and SU-82000 diluent according to the volume ratio of 1:6, spread 0.5ml of the diluted photoresist evenly on the 5cm diameter chromatographic paper, and dry at room temperature for 2min Afterwards, directly align the mask film with the chromatographic paper on a photolithography machine (OL-2Mask Aligner, AB-M, Inc) and expose for 30s, develop with acetone for 5min, to obtain a paper cover sheet with microchannels;

[0040] B. Production of paper-based substrates

[0041] press figure 1 As shown in (c), use ordinary A4 paper cut into a certain size of paper as a mask, and cut off the electrode area of the paper according to the size and shape of the electrode designed on the chromatographic paper, and place the finished paper mask on the chromatogram On the paper, magnetron sputtering tin indium oxide film is used to obtain 100nm thick nano-electrodes and bipolar electr...

Embodiment 2

[0045] A. Paper-based cover sheet production

[0046] according to figure 1 (B) Dilute the photoresist SU-82150 and chloroform in a volume ratio of 1:4, and evenly spread 0.5ml of the diluted photoresist on a 5cm diameter chromatographic paper. After drying at room temperature for 2 minutes, directly Align the mask film with the chromatographic paper on a photolithography machine (OL-2Mask Aligner, AB-M, Inc) and expose for 30s, and develop with acetone for 5min to obtain a paper cover film with microchannels;

[0047] B. Production of paper-based substrates

[0048] press figure 1 As shown in (c), use ordinary A4 paper cut into a certain size of paper as a mask, and cut off the electrode area of the paper according to the size and shape of the electrode designed on the chromatographic paper, and place the finished paper mask on the chromatogram On the paper, the Au film is sputtered by magnetron to obtain 100nm thick nano-electrodes and bipolar electrodes; the bipolar electrode ...

Embodiment 3

[0053] A. Paper-based cover sheet production

[0054] according to figure 1 (B) Dilute the photoresist SU-8100 and cyclopentanone in a volume ratio of 1:8, and evenly spread 0.5ml of the diluted photoresist on a 5cm diameter chromatographic paper. After drying at room temperature for 2 minutes, Directly align the mask film with the chromatographic paper on a photolithography machine (OL-2Mask Aligner, AB-M, Inc) and expose for 30s, and develop with acetone for 5min to obtain a paper cover sheet with microchannels;

[0055] B. Production of paper-based substrates

[0056] press figure 1 As shown in (c), use ordinary A4 paper cut into a certain size of paper as a mask, and cut off the electrode area of the paper according to the size and shape of the electrode designed on the chromatographic paper, and place the finished paper mask on the chromatogram On the paper, magnetron sputtering platinum film is used to obtain 100nm thick nano-electrodes and bipolar electrodes; the bipolar e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com