Preparation method of titanium alloy cast ingot containing high-melting-point elements

A high melting point metal and titanium alloy technology, applied in the field of titanium alloy preparation, can solve the problems of electrode block drop, influence on ingot quality, electrode strength reduction and other problems, and achieve the effects of quality assurance, reasonable smelting process design and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

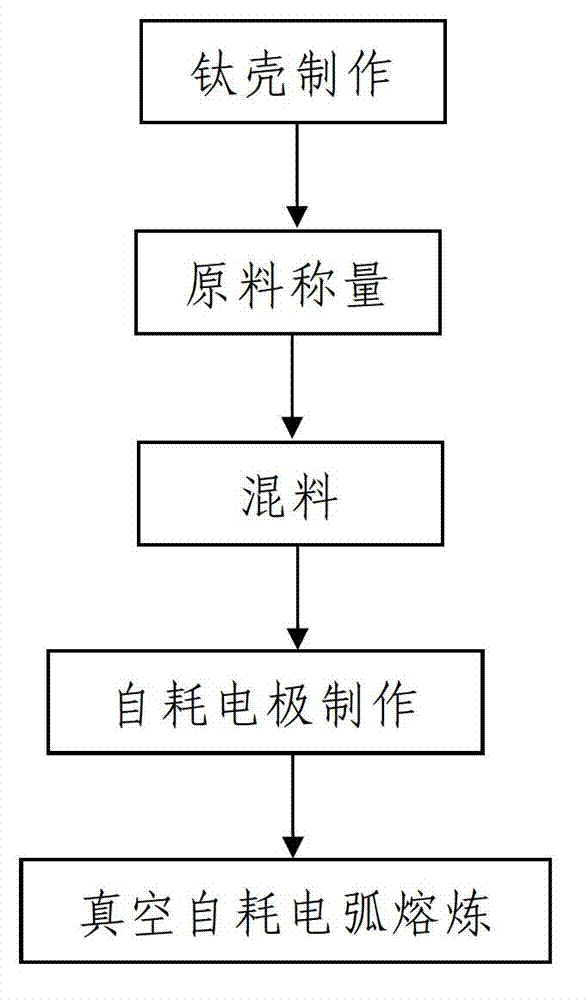

[0039] like figure 1 A preparation method of a titanium alloy ingot containing high melting point elements is shown, comprising the following steps:

[0040] Step 1. Weighing of raw materials: Proportion weighing of raw materials is carried out according to the nominal chemical composition of the titanium alloy to be prepared; the raw materials include fine particle sponge titanium with a particle size below 4mm, a titanium shell wrapped on the outside of the electrode block to be made and High-melting-point metal powder with a particle size of 80 mesh or less, and the melting point of the high-melting-point alloy element is higher than 2000°C.

[0041] During actual preparation, the high melting point alloy element is one or more of W, Ta, Mo and Nb. And, the mass percentage of the high melting point metal powder is above 15%.

[0042] Step 2, mixing materials: uniformly mix the fine particle titanium sponge and high-melting point metal powder weighed in step 1 to obtain a ...

Embodiment 1

[0051] In this embodiment, the nominal chemical composition of the titanium alloy to be prepared is Ti-30W, wherein the weight percentage of W element is 30%, and the balance is Ti and unavoidable impurities.

[0052] In this embodiment, a method for preparing a titanium alloy ingot containing high melting point elements is required, comprising the following steps:

[0053] Step 1. Weighing of raw materials: Proportion weighing of raw materials is carried out according to the nominal chemical composition of the titanium alloy to be prepared; the raw materials include fine particle sponge titanium with a particle size below 4mm, a titanium shell wrapped on the outside of the electrode block to be made and The particle size is 200 mesh tungsten powder.

[0054] Step 2, mixing materials: uniformly mix the fine particle titanium sponge and tungsten powder weighed in step 1 to obtain a uniform mixture.

[0055] In this embodiment, when the fine particle titanium sponge and tungste...

Embodiment 2

[0094] In this embodiment, the difference from Example 1 is that the nominal composition of the titanium alloy to be prepared in step 1 is Ti-32Mo, wherein the weight percentage of the Mo element is 30%, and the balance is Ti and unavoidable impurities; The selected raw materials include fine-grained titanium sponge with a particle size of less than 4 mm, a titanium shell wrapped on the outside of the electrode block to be made, and molybdenum powder with a particle size of 150 mesh. The fine-grained titanium sponge is grade 0 sponge titanium; the electrode made in step 3 The size is Φ160mm×300mm, the titanium plate used to process the first titanium sheet and the second titanium sheet is a rectangular plate, the size of the first titanium sheet and the second titanium sheet is 250mm×300mm and the thickness of both is 2mm; Since the raw materials include fine-grain sponge titanium, titanium shells and high-melting-point metal powders, before step 1 carries out proportioning wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com