Environment-friendly flame retardant glass fiber reinforced polybutylece terephthalate/ polyethylene terephthalate (PBT/ PET) alloy material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value and preparation method thereof

An alloy material, environmental protection technology, applied in the field of alloy materials, to achieve the effects of environmental protection of composite materials, improvement of processing fluidity, high GWIT value and CTI value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

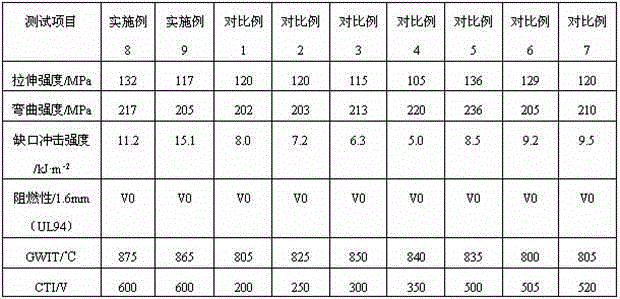

Examples

Embodiment 1

[0039] Preparation of Example 1 PBT / PET alloy material (1)

[0040]The intrinsic viscosity of PBT is 1.0 dL / g, and the intrinsic viscosity of PET is 1.0 dL / g. The composite flame retardant is composed of 50% by weight of BPS, 25% of magnesium hypophosphite and 25% of talcum powder. Glass The fiber is an alkali-free glass fiber whose surface is treated with a silane coupling agent, the toughening agent is ethylene-methyl acrylate-glycidyl methacrylate random terpolymer, the antioxidant is antioxidant 1330, and the oxide is iron oxide.

[0041] Weigh each raw material component according to the following weight percentage content: PBT 22.5%, PET 22.5%, compound flame retardant 20%, antimony trioxide 4%, glass fiber 20%, toughening agent 10%, antioxidant 0.1%, oxide 0.9%. Put the weighed raw materials into a high-mixer, mix for 2 minutes, discharge, and then extrude and granulate with a twin-screw extruder; the processing temperature of the twin-screw extruder is 230-240°C. T...

Embodiment 2

[0042] Preparation of Example 2 PBT / PET Alloy Material (2)

[0043] The intrinsic viscosity of PBT is 0.8 dL / g, and the intrinsic viscosity of PET is 1.0 dL / g. The composite flame retardant is composed of 50% by weight of BPS, 25% of magnesium hypophosphite and 25% of talcum powder. Glass The fiber is an alkali-free glass fiber whose surface is treated with a silane coupling agent, the toughening agent is ethylene-methyl acrylate-glycidyl methacrylate random terpolymer, the antioxidant is antioxidant 1010, and the oxide is iron oxide.

[0044] The raw material components were weighed according to the following weight percentages: 41% PBT, 23% PET, 6% compound flame retardant, 3% antimony trioxide, 20% glass fiber, 5% toughening agent, antioxidant 1%, oxide 1%. Put the weighed raw materials into a high-mixer, mix for 5 minutes, discharge, and then extrude and granulate with a twin-screw extruder; the processing temperature of the twin-screw extruder is 230-240°C. The machi...

Embodiment 3

[0045] Example 3 Preparation of PBT / PET Alloy Material (3)

[0046] The intrinsic viscosity of PBT is 1 dL / g, and the intrinsic viscosity of PET is 0.8 dL / g. The composite flame retardant is composed of 50% by weight of BPS, 25% of magnesium hypophosphite and 25% of talcum powder. The toughening agent is ethylene-methyl acrylate binary copolymer, the antioxidant is antioxidant 1330, and the oxide is aluminum oxide.

[0047] Weigh each raw material component according to the following weight percentage content: PBT 23%, PET 23%, compound flame retardant 6%, antimony trioxide 15%, glass fiber 30%, toughening agent 2%, antioxidant 0.9%, oxide 0.1%. Put the weighed raw materials into a high-mixer, mix for 3 minutes, discharge, and then extrude and granulate with a twin-screw extruder; the processing temperature of the twin-screw extruder is 230-240° C. The machine includes nine temperature zones, one of which is 230°C for the first stage, 230°C for the second stage, 235°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com