Preparation method of micro-bridge structured infrared detector, and micro-bridge structure

A technology of infrared detector and micro-bridge structure, which is applied in the direction of micro-structure technology, micro-structure device, manufacturing micro-structure device, etc., can solve the problems affecting the sensitivity and response rate of the detector, the increase of production cost, and the poor heat insulation of bridge pier, etc., to achieve Improve structural strength and mechanical properties and reliability, reduce process costs, and enhance the effect of supporting thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

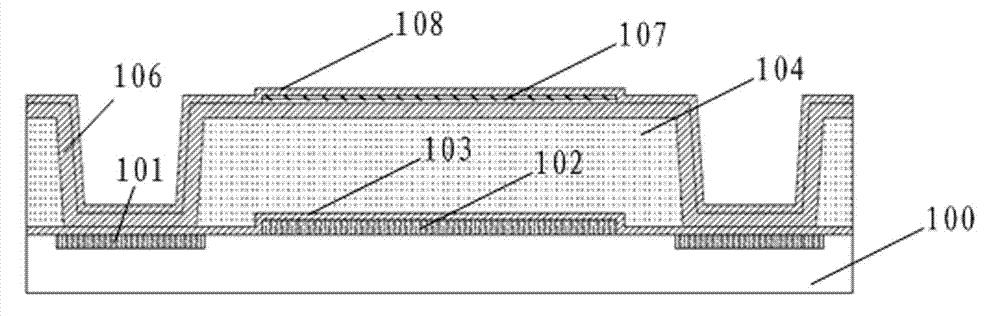

[0044] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

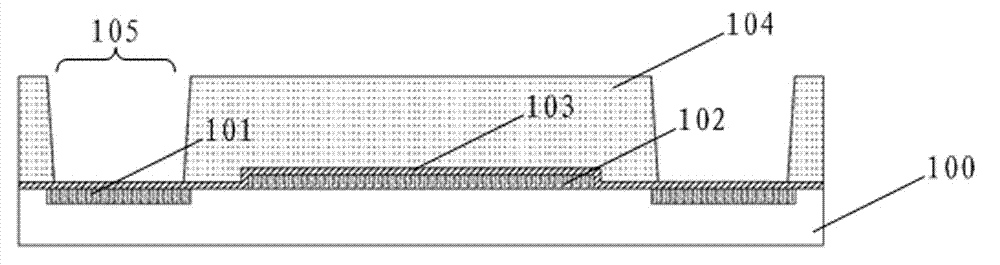

[0045] The invention provides a method for preparing an infrared detector with a microbridge structure, see Figure 1 to Figure 7 , its specific process steps are as follows:

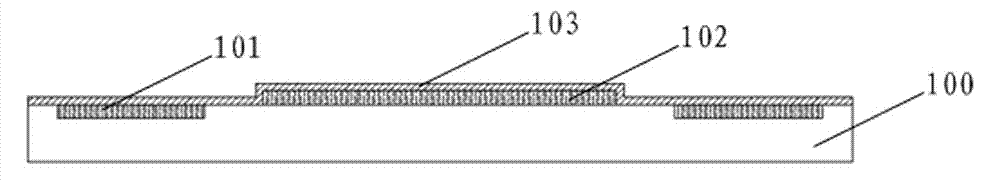

[0046] like figure 1 As shown, firstly, a metal reflective layer 102 is fabricated on a wafer of a readout circuit substrate 100 of a processed Si substrate. The metal material of the reflective layer 102 is Al or Ti, and the metal thin film is grown by magnetron sputtering (PVD) or electron beam evaporation, and then a reflective layer (Mirror) pattern is formed on the metal thin film by photolithography and etching. The metal of the reflective layer 102 has a reflectivity of more than 90% for infrared light of a specific wavelength (such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com