High-alkalinity band electrode electroslag surfacing flux

A high-basicity, band-polarized technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of high price and general application effect, and achieve high production efficiency and small machining allowance after welding. , the effect of low comprehensive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

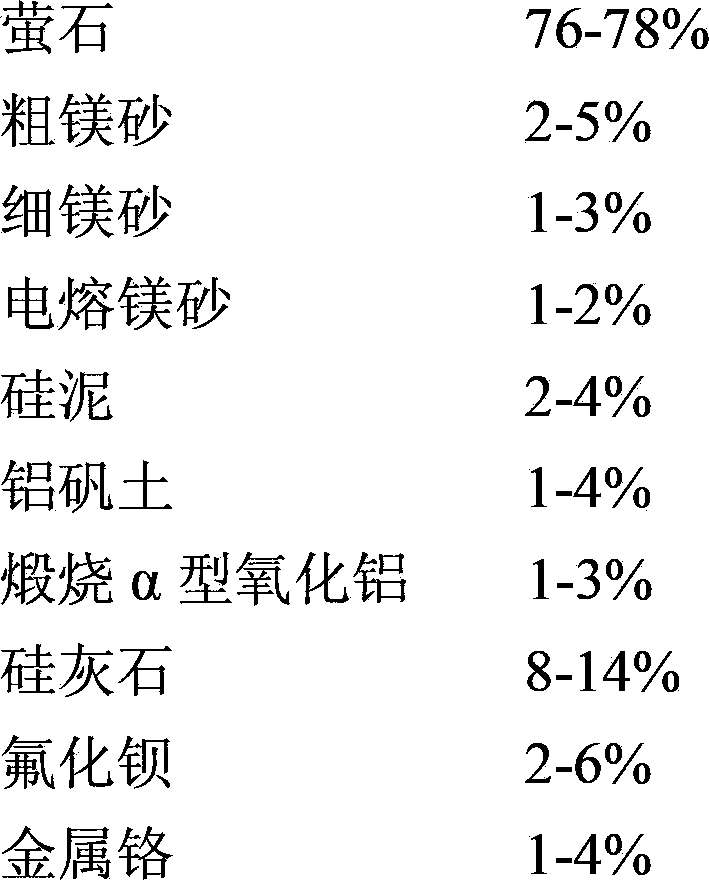

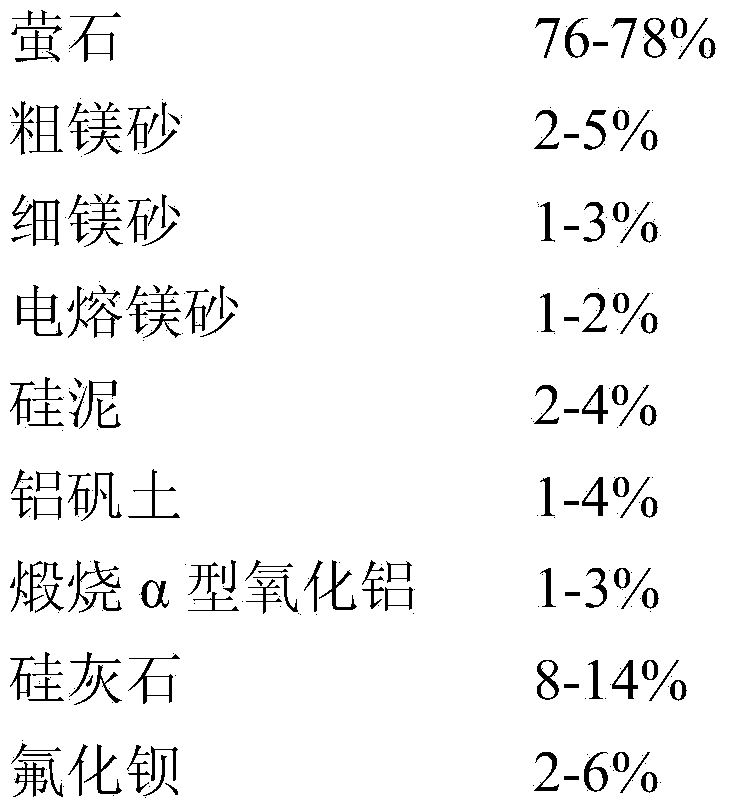

[0031] (1) A high-alkalinity strip electroslag surfacing flux, the formula of the flux is 76% of fluorite, 3% of coarse magnesia, 1% of fine magnesia, 2% of fused magnesia, 2% of silica mud, Bauxite 4%, calcined α-alumina 1%, wollastonite 8%, barium fluoride 2%, metal chromium 1%. CaF in fluorite 2 Content ≥ 92%, MgO in coarse magnesia ≥ 88%, MgO in fine magnesia ≥ 88%, MgO in fused magnesia ≥ 97%, SiO in silica mud 2 ≥97%, Al in bauxite 2 o 3 ≥75%, CaO≥38% and SiO in wollastonite 2 ≥42%.

[0032] (2) Chemical composition of stainless steel welding strip:

[0033]

[0034] (3) Chemical composition of transition layer welding strip JQ.EQ309L:

[0035]

[0036] (4) Regulations on the use of welding strips when inspecting the chemical composition of various types of surfacing metals:

[0037] Corrosion Hardfacing Metal Models

Transition layer surfacing welding strip model

Corrosion-resistant surfacing welding strip model

F×308L-E

JQ.EQ309L...

Embodiment 2

[0050] (1) A high-alkalinity strip electroslag surfacing flux, the formula of the flux is 77% of fluorite, 2% of coarse magnesia, 2% of fine magnesia, 1% of fused magnesia, 3% of silica mud, Bauxite 1%, calcined α-alumina 3%, wollastonite 8%, barium fluoride 2%, metal chromium 1%. CaF in fluorite 2 Content ≥ 92%, MgO in coarse magnesia ≥ 88%, MgO in fine magnesia ≥ 88%, MgO in fused magnesia ≥ 97%, SiO in silica mud 2 ≥97%, Al in bauxite 2 o 3 ≥75%, CaO≥38% and SiO in wollastonite 2 ≥42%.

[0051] (2) Chemical composition of stainless steel welding strip:

[0052]

[0053](3) Chemical composition of transition layer welding strip JQ.EQ309L:

[0054]

[0055] (4) Regulations on the use of welding strips when inspecting the chemical composition of various types of surfacing metals:

[0056] Corrosion Hardfacing Metal Models

[0057] (5) Chemical composition of surfacing metal:

[0058]

[0059] (6) Percentage of surfacing metal ferrite:

[0060]

...

Embodiment 3

[0070] (1) A high-alkalinity strip electroslag surfacing flux, the formula of the flux is 76.5% of fluorite, 2.5% of coarse magnesia, 1.5% of fine magnesia, 1% of fused magnesia, 2% of silica mud, Bauxite 2%, calcined α-alumina 2%, wollastonite 9%, barium fluoride 2%, metal chromium 1.5%. CaF in fluorite 2 Content ≥ 92%, MgO in coarse magnesia ≥ 88%, MgO in fine magnesia ≥ 88%, MgO in fused magnesia ≥ 97%, SiO in silica mud 2 ≥97%, Al in bauxite 2 o 3 ≥75%, CaO≥38% and SiO in wollastonite 2 ≥42%.

[0071] (2) Chemical composition of stainless steel welding strip:

[0072]

[0073] (3) Chemical composition of transition layer welding strip JQ.EQ309L:

[0074]

[0075] (4) Regulations on the use of welding strips when inspecting the chemical composition of various types of surfacing metals:

[0076] Corrosion Hardfacing Metal Models

Transition layer surfacing welding strip model

Corrosion-resistant surfacing welding strip model

F×308L-E

J...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com