Low-chromium hard-wearing grinding ball and processing technology thereof

A processing technology and grinding ball technology, applied in the field of low-chromium wear-resistant grinding balls and their processing technology, can solve the problems that the production capacity cannot reach the expected target, the impact toughness index is not specified, and the production cost of high-chromium grinding balls is high. Strict control of cooling temperature and time, long service life and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

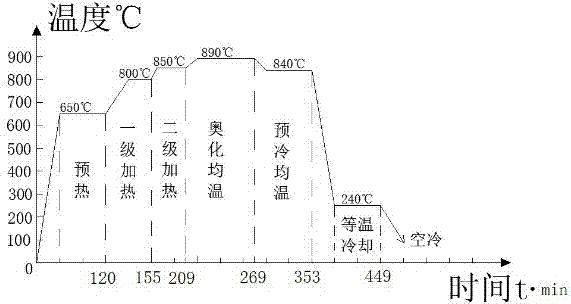

[0039] The diameter of the low chromium wear-resistant grinding ball is 100mm, and its quenching process comprises the following steps:

[0040] (1) Preheating stage: preheating temperature 650°C, time 120min;

[0041] (2) Primary heating stage: heating temperature 800°C, time 35min;

[0042] (3) Secondary heating stage: heating temperature 850°C, time 54min;

[0043] (4) Austrianization uniform temperature stage: constant temperature 890 ° C, time 60 minutes;

[0044] (5) Pre-cooling and uniform temperature stage: constant temperature 840 ℃, time 84min;

[0045] (6) Isothermal cooling stage: cooling to 240°C for 96 minutes.

[0046] (7) Air cooling stage: cooling to room temperature.

Embodiment 2

[0048] The diameter of described low chromium wear-resistant grinding ball is 130mm, and its quenching process comprises the following steps:

[0049] (1) Preheating stage: preheating temperature 650°C, time 150min;

[0050] (2) Primary heating stage: heating temperature 800°C, time 44min;

[0051] (3) Secondary heating stage: heating temperature 850°C, time 66min;

[0052] (4) Austrianization uniform temperature stage: constant temperature 890 ℃, time 75min;

[0053] (5) Pre-cooling and uniform temperature stage: constant temperature 840°C, time 105min;

[0054] (6) Isothermal cooling stage: cooling to 240°C for 120 minutes.

[0055] (7) Air cooling stage: cooling to room temperature.

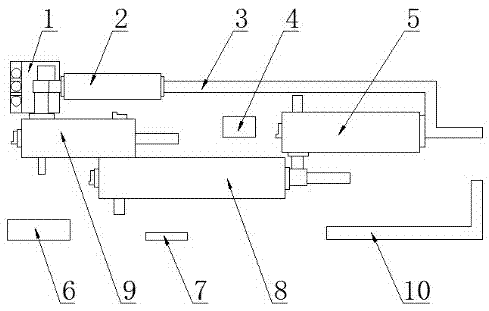

[0056]The present invention adopts the CADI grinding ball continuous isothermal quenching oil cooling line to prepare the low-chromium wear-resistant grinding ball, and the CADI grinding ball continuous isothermal quenching oil cooling line includes a quenching tank 1, an isothermal furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com