Wall-flow honeycomb ceramic filter for high-temperature exhaust gas purification, and preparation method thereof

A technology of honeycomb ceramics and high-temperature waste gas, applied in ceramic products, applications, household appliances, etc., can solve the problems of low porosity, poor thermal shock resistance, low strength, etc., achieve high porosity, promote sintering, and easy to control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

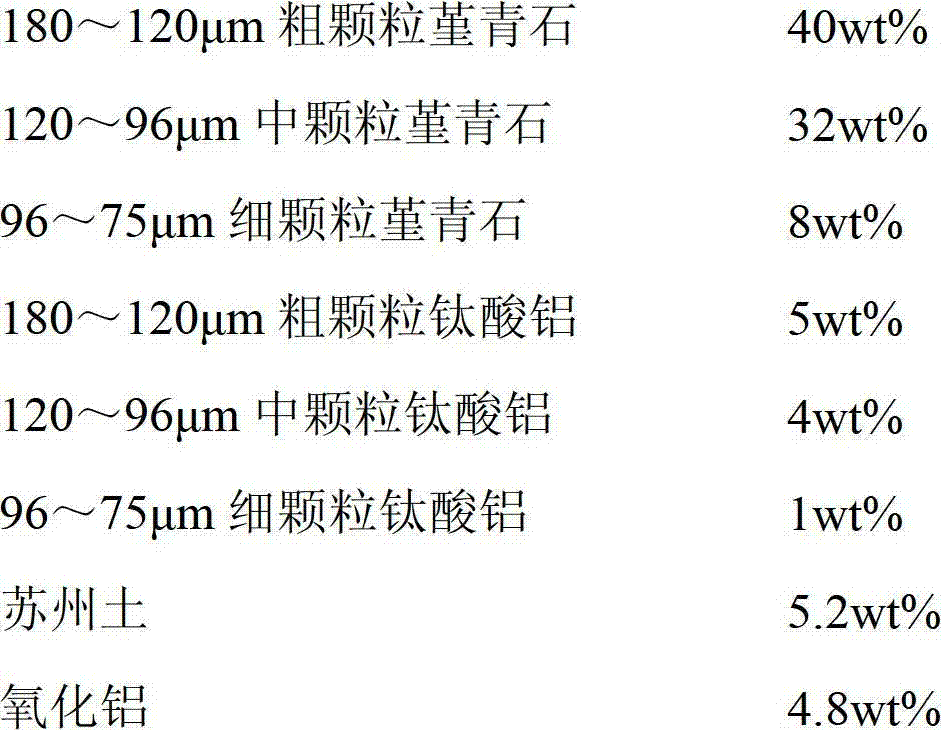

[0025] 1. The wall-flow honeycomb ceramic filter body for purification of high-temperature exhaust gas in this embodiment, the composition of its basic raw materials is:

[0026]

[0027] In addition, based on the above basic raw materials, add: pore-forming agent walnut shell powder (100-120 μm, the same below) 2.2wt%, hydroxypropyl methylcellulose 6wt%, glycerin 4wt%, water 23wt%.

[0028] 2. The preparation method of the wall-flow honeycomb ceramic filter body for high-temperature exhaust gas purification in this embodiment is as follows:

[0029] (1) Add Suzhou soil, alumina, and pore-forming agent into the mixer, and add hydroxypropyl methylcellulose and mix together for 30 minutes; then add cordierite and aluminum titanate and mix for 30 minutes to obtain a mixed material;

[0030] (2) Add glycerin and water to the mixed material and mix for 30 minutes to obtain mud;

[0031] (3) The mud material is prepared into a mud section through aging and vacuum mud refining, a...

Embodiment 2

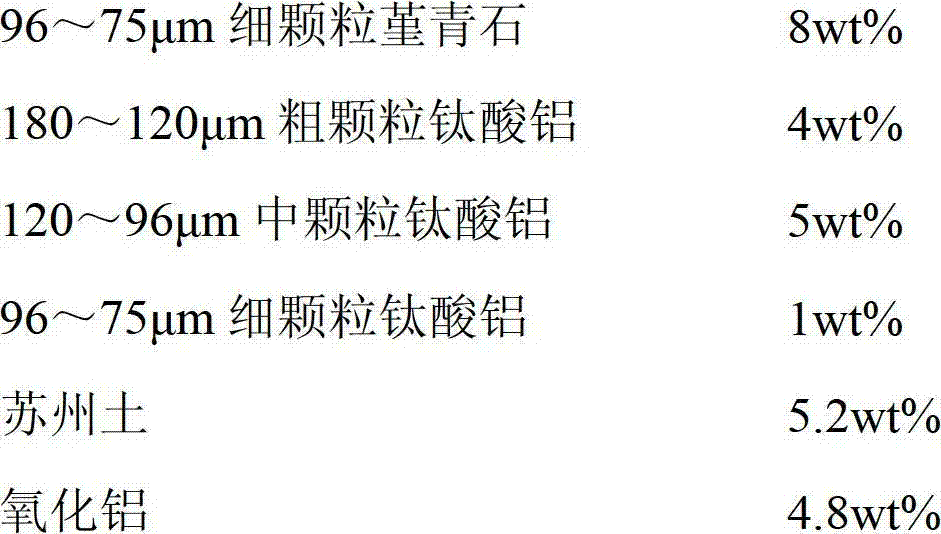

[0035] 1. The wall-flow honeycomb ceramic filter body for purification of high-temperature exhaust gas in this embodiment, the composition of its basic raw materials is:

[0036]

[0037]

[0038] In addition, based on the above-mentioned basic raw materials, 2.2wt% of walnut shell powder, 6wt% of hydroxypropyl methylcellulose, 4wt% of glycerin, and 23wt% of water were added.

[0039] 2. The preparation method of the wall-flow honeycomb ceramic filter body for purifying high-temperature exhaust gas in this embodiment is the same as that in Embodiment 1.

[0040]3. The performance indicators of the wall-flow honeycomb ceramic filter body in this embodiment are as follows: porosity 45.2%, compressive strength 26.5MPa, average pore diameter 15.0μm, thermal expansion coefficient 1.63×10 -6 / ℃, thermal stability 20 ~ 850 ℃ air cooling once without cracking.

Embodiment 3

[0042] 1. The wall-flow honeycomb ceramic filter body for purification of high-temperature exhaust gas in this embodiment, the composition of its basic raw materials is:

[0043]

[0044] In addition, based on the above-mentioned basic raw materials, 2.2wt% of walnut shell powder, 6wt% of hydroxypropyl methylcellulose, 4wt% of glycerin, and 23wt% of water were added.

[0045] 2. The preparation method of the wall-flow honeycomb ceramic filter body for high-temperature exhaust gas purification in this embodiment is as follows:

[0046] (1) Add Suzhou soil, alumina, and pore-forming agent into the mixer, and add hydroxypropyl methylcellulose and mix together for 60 minutes; then add cordierite and aluminum titanate and mix for 40 minutes to obtain a mixed material;

[0047] (2) Add glycerin and water to the mixed material and mix for 60 minutes to obtain mud;

[0048] (3) The mud material is prepared into a mud section through aging and vacuum mud refining, and is extruded o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com