Anti-after tack acrylic latex for water-based ink

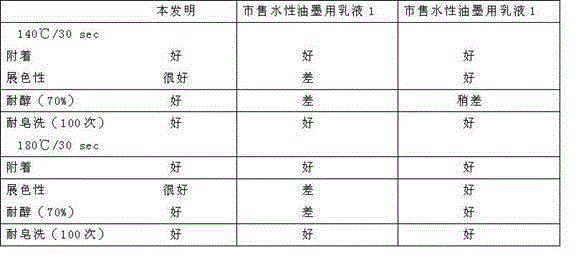

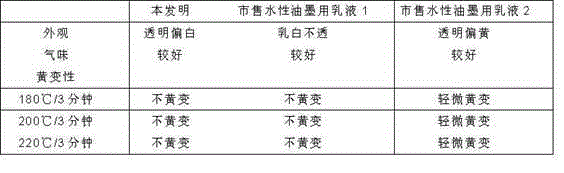

A technology of water-based ink and pure acrylic emulsion, which is applied in the direction of ink, application, household appliances, etc. It can solve the problems of affecting the color development and soaping resistance of water-based ink, compatibility affecting the stability of emulsion polymerization, and high production equipment requirements. , achieve excellent yellowing resistance, easy operation, and improve alcohol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of alkali-soluble resin: Add 750g of water, 12g of sodium lauryl sulfate, 10g of sodium lauryl polyoxyethylene ether sulfate, and 5g of sodium persulfate into the reaction kettle under mechanical stirring at a temperature of 60°C, and stir evenly Afterwards, add methacrylic acid 30g, methyl methacrylate 125g, n-butyl acrylate 20g, ethyl acrylate 20g and 5g 3-mercaptopropionic acid and 3g 3-mercaptopropionic acid butyl ester to carry out radical polymerization, reaction temperature is at 20 Rise to 85°C within 1 minute, and control the temperature in this range for 60 minutes, then lower the temperature to 60°C, add 20g of ammonia water, and discharge to obtain a self-made alkali-soluble resin solution.

[0043] Then, the self-made alkali-soluble resin solution of 500g is mixed with 450g methyl methacrylate, 100g butyl acrylate and 10g hydroxyethyl methacrylate under high-speed stirring to make a pre-emulsion;

[0044] Then add the remaining 500g homemade alk...

Embodiment 2

[0047]Preparation of alkali-soluble resin: Add 700g of water, 10g of sodium lauryl sulfate, 3g of sodium lauryl polyoxyethylene ether sulfate, fatty alcohol polyoxyethylene ether amber Disodium sulfonic acid 5g, ammonium persulfate 8g, after stirring evenly, add 42g of methacrylic acid, 124g of methyl methacrylate, 20g of n-butyl acrylate, 50g of ethyl acrylate and 5g of 3-mercaptopropionic acid for radical polymerization , the reaction temperature rises to 81°C within 30 minutes, and the temperature is controlled within this range for 60 minutes, then the temperature is lowered to 70°C, 33g of ammonia water is added, and the self-made alkali-soluble resin solution is obtained by discharging.

[0048] Then, under high-speed stirring, 700g of homemade alkali-soluble resin solution and 350g of methyl methacrylate, 100g of ethyl acrylate, 50g of butyl methacrylate and 10g of diethylaminoethyl methacrylate were mixed evenly to make a pre-emulsion ;

[0049] Then add the remaining...

Embodiment 3

[0052] Preparation of alkali-soluble resin: 711 g of water, 10 g of sodium lauryl sulfate, 10 g of disodium salt of fatty alcohol polyoxyethylene ether succinate sulfonate, and 3 g of sodium persulfate were added to the reaction kettle under mechanical stirring at a temperature of 50 ° C. After stirring evenly, add 42g of methacrylic acid, 134g of methyl methacrylate, 55g of ethyl acrylate and 5g of 3-mercaptopropionic acid to carry out free radical polymerization. The reaction temperature rises to 85°C within 20 minutes, and the temperature is controlled within 60°C. Minutes, then lower the temperature to 60°C, add 30g of ammonia water, and discharge to obtain a self-made alkali-soluble resin solution.

[0053] Then, under high-speed stirring, the self-made alkali-soluble resin solution of 500g and 400g methyl methacrylate, 100g butyl acrylate and 20g vinyltriethoxysilane were mixed uniformly to make a pre-emulsion;

[0054] Then add the remaining 500g homemade alkali-soluble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com