Emulsion pressure sensitive adhesive for anti-yellowing surface protective film and preparation method thereof

A surface protection film and anti-yellowing technology, which is applied in the direction of pressure-sensitive films/sheets, adhesives, film/sheet-shaped adhesives, etc., can solve the problems affecting product appearance and performance, yellowing of protective films, etc., to achieve Excellent anti-yellowing performance, good conformability, and the effect of meeting the performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

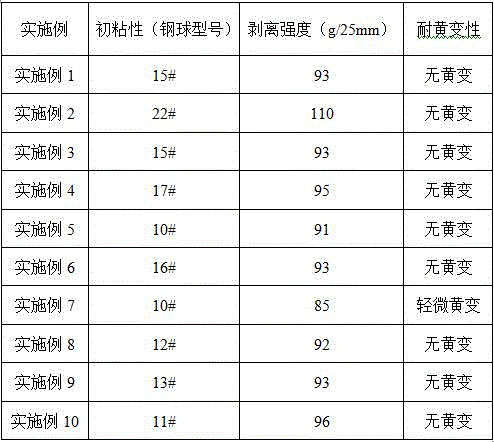

Examples

Embodiment approach 1

[0047]Embodiment 1, an emulsion pressure-sensitive adhesive for an anti-yellowing surface protective film, which is prepared by polymerizing the raw materials of each component in a reactor. Calculated by weight percentage, the raw materials of each component include:

[0048] Soft monomer 40.5%~45.5%;

[0049] Hard monomer 1.3%~4.3%;

[0050] Functional monomer 1.7%~3.3%;

[0051] Emulsifier 0.8~2.2%;

[0052] Initiator 0.2~0.5%;

[0053] Buffer 0.1~0.2%;

[0054] Neutralizer 0.4~1.3%;

[0055] Oxidant 0.05~0.2%;

[0056] Reducing agent 0.05~0.2%;

[0057] Deionized water 47.5% to 52.5%.

Embodiment approach 2

[0058] Embodiment 2 is the same as Embodiment 1, the difference is that the soft monomer is selected from the group consisting of butyl acrylate, isooctyl acrylate, isooctyl methacrylate, ethyl acrylate, lauryl acrylate, and stearyl acrylate. Any one or a combination of several;

[0059] The hard monomer is selected from any one or a combination of methyl methacrylate, methyl acrylate, and acrylonitrile;

[0060] The functional monomer is selected from any one or a combination of hydroxyethyl acrylate, hydroxypropyl acrylate, acrylic acid, methacrylic acid, hydroxyethyl methacrylate, hydroxypropyl methacrylate, and acrylamide.

Embodiment approach 3

[0061] Embodiment 3, the same as Embodiment 1, the difference is that the emulsifier is an anionic emulsifier selected from sodium dodecyl diphenyl ether disulfonate, sodium lauryl sulfate, allyloxy hydroxypropyl Any one or combination of sodium sulfonate, nonylphenol polyoxyethylene ether ammonium sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com