Self-crosslinking silicone-acrylate copolymer emulsion and preparation method

A polymer emulsion, self-crosslinking technology, applied in the direction of coating, etc., can solve the problems of poor stability, poor stain resistance, etc., to improve product cost performance, excellent stain resistance, good reaction stability and storage stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

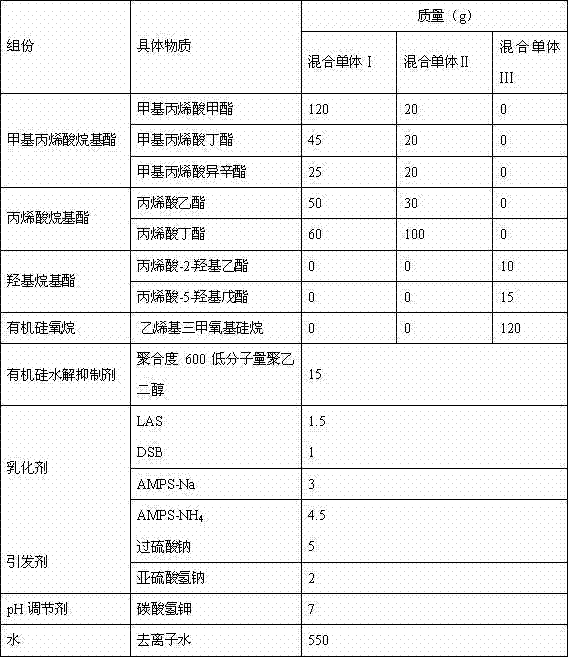

[0044] (1) The components of the self-crosslinking silicone acrylic polymer emulsion are shown in Table 1 below:

[0045]

[0046] (2) Mix the above-mentioned methyl methacrylate, butyl acrylate, 2-hydroxyethyl acrylate and vinyltriethoxysilane respectively to prepare monomer I, monomer II and monomer III;

[0047] (3) Preparation of seed emulsion: Add 80% of the above-mentioned deionized water, 70% of the mixture of SDS and AMPS, 60% of the mixture of potassium persulfate and sodium bisulfite, sodium bicarbonate, and propylene glycol to a thermometer equipped with , stirrer, feeding tube, and condensing reflux tube, stir and disperse for 15 minutes, wait for the temperature to rise to 68 ° C, drop the monomer I within 3 hours, and keep warm for 15 minutes after the dropping to make a seed emulsion ;

[0048] (4) Within 1.5 hours, slowly add monomer III to monomer II and keep stirring to mix evenly, then mix the mixture of monomer II and monomer III and the remaining deion...

Embodiment 2

[0052] (1) The components of the self-crosslinking silicone acrylic polymer emulsion are shown in Table 2 below:

[0053]

[0054] (2) The above-mentioned methyl methacrylate, ethyl methacrylate, butyl acrylate, pentyl acrylate, 2-hydroxyethyl acrylate, 3-hydroxypropyl acrylate, γ-methacryloxypropyl Trimethoxysilane was mixed separately to make monomer I, monomer II and monomer III;

[0055] (3) Preparation of seed emulsion: 70% of the above mass of deionized water, 65% of the mass of the mixture of DBS and HAPS, 50% of the mass of the mixture of ammonium persulfate and potassium bisulfite, sodium bicarbonate, 1,4 butanediol Add it into the reaction kettle equipped with a thermometer, agitator, feeding tube, and condensing reflux tube, stir and disperse for 10 minutes, wait until the temperature rises to 65°C, drop the monomer I in 3.5 hours, and keep it warm for 20 minutes after the dropping is completed. Make seed emulsion;

[0056] (4) Within 2 hours, slowly add monome...

Embodiment 3

[0060] (1) The components of the self-crosslinking silicone acrylic polymer emulsion are shown in Table 3 below:

[0061]

[0062] (2) Mix the above-mentioned ethyl methacrylate, propyl methacrylate, butyl acrylate, 2-hydroxyethyl acrylate, 5-hydroxypentyl acrylate and vinyl tributoxysilane to make a mixed unit Body I, Mixed Monomer II and Mixed Monomer III;

[0063] (3) Preparation of seed emulsion: the above-mentioned 75% deionized water, LAS and AMPS-NH 4 60% of the mass of the mixture, 70% of the mass of the mixture of potassium persulfate and sodium bisulfite, potassium bicarbonate, and low molecular weight polyethylene glycol with a degree of polymerization of 400 are added to the reaction equipped with a thermometer, agitator, feeding tube, and condensing reflux tube In the kettle, stir and disperse for 20 minutes. When the temperature rises to 70 °C, add the mixed monomer I dropwise in 4 hours, and keep it warm for 30 minutes after the dropwise addition to make a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com