Method for preparing low-temperature-resistant corrosion-resistant wind-power spherulitic graphite cast iron

A nodular cast iron, corrosion-resistant technology, applied in the direction of improving process efficiency, etc., can solve the problems of poor impact toughness and corrosion resistance, achieve the effects of reducing corrosion current, high thermodynamic stability, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

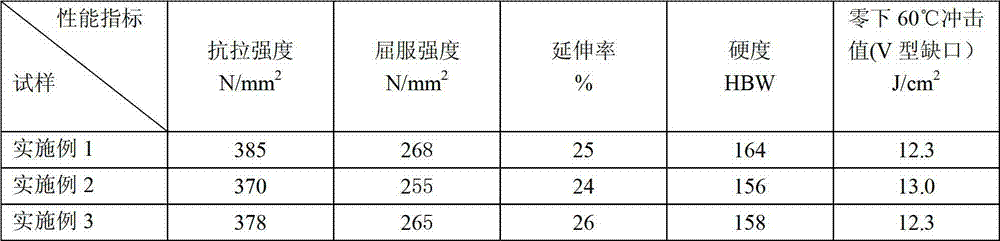

Examples

specific Embodiment approach 1

[0013] Embodiment 1: A method for preparing a low-temperature-resistant and corrosion-resistant wind power nodular cast iron according to this embodiment is carried out in the following steps:

[0014] 1. Smelting molten iron: First, the mass parts of Q10 pig iron and scrap steel are 60~80 and 20~40, weigh Q10 pig iron and scrap steel, and then according to the mass of recarburizer for ball milling cast iron and the total mass of Q10 pig iron and scrap steel The ratio is (3~5): 100, according to the ratio of the mass of nickel plate to the total mass of Q10 pig iron and steel scrap is (1~1.5): 100, weigh the recarburizer and nickel plate for ball milled cast iron, and then weigh Add the recarburizer and nickel plate for Q10 pig iron, steel scrap, and ball-milled cast iron into the intermediate frequency furnace, raise the temperature to 1500~1550°C, let it stand for 2~4 minutes, and take it out of the furnace to obtain molten iron;

[0015] 2. Spheroidization and inoculation t...

specific Embodiment approach 2

[0018] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: in step 1, the total amount of impurities in Q10 pig iron ∑T≤0.1%, the components in scrap steel and the mass fraction of each component are: C: 0.17%~0.21% , S: 0.012%~0.016%, P: 0.020%~0.024%, Mn: 0.26%~0.30%, Si: 0.30%~0.40%, and other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019] Specific embodiment three: what this embodiment is different from specific embodiment one or two is: the mass fraction of Q10 pig iron and steel scrap is 70 and 30 in the step 1, the quality of ball milling cast iron carburizer and the total amount of Q10 pig iron and steel scrap The mass ratio is 1:25, and the other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com