Bionic dental implant and preparation method thereof

A technology of implants and bionic teeth, which is applied in prosthetics, tissue regeneration, pharmaceutical formulations, etc., can solve the problems of hard-to-bear oral stress environment, reduced strength and rigidity, etc., and achieve the improvement of implant success rate, monomer utilization rate, Excellent abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

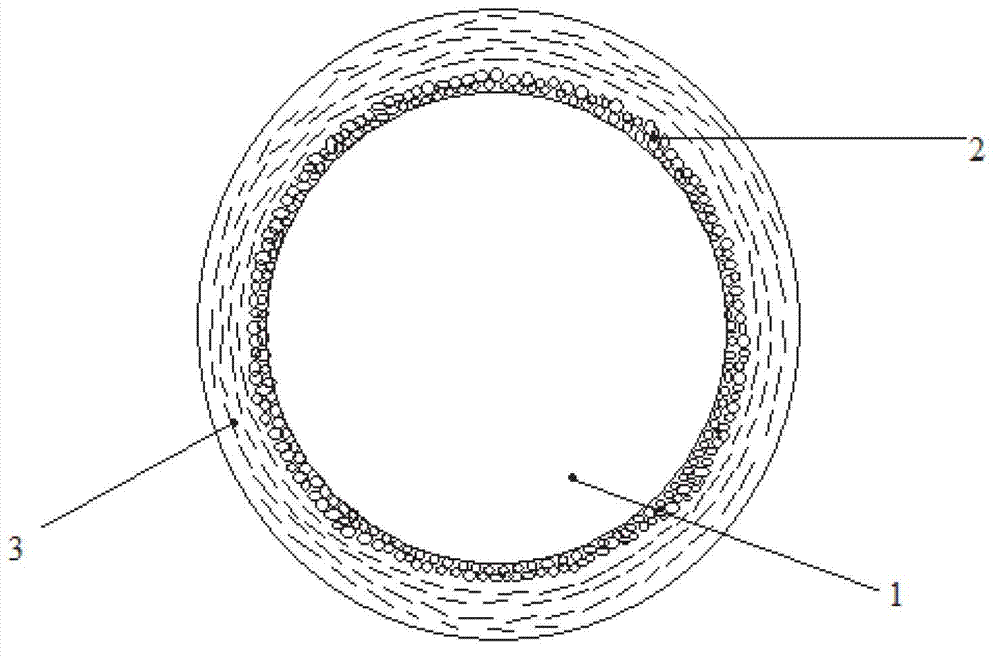

Image

Examples

Embodiment 1

[0025] In this embodiment, the process steps for preparing the bionic dental implant are as follows:

[0026] ① The titanium matrix is a bone screw with a diameter of 4.5mm and a length of 12mm. The titanium matrix is treated with a mixed acid composed of hydrochloric acid and sulfuric acid. The mass concentration of hydrochloric acid is 36%, and the mass concentration of sulfuric acid is 98%. Prepare 20ml Mixed acid, in the mixed acid, the volume ratio of hydrochloric acid to sulfuric acid is 1:1, the treatment method: put the polished titanium substrate into the beaker containing the mixed acid, seal the beaker with plastic wrap and put In a water bath at 60°C, keep the temperature constant for 30 minutes, take out the titanium substrate, and put the titanium substrate in an oven to dry at 50°C;

[0027] Electron beam melting technology is used to deposit titanium dioxide powder layer by layer on the surface of the acid-treated pure titanium substrate to form a porous ti...

Embodiment 2

[0033] In this embodiment, the process steps for preparing the bionic dental implant are as follows:

[0034] ① The titanium matrix is a bone screw with a diameter of 4.5 mm and a length of 12 mm. The acid treatment of the titanium matrix is the same as in Example 1; electron beam melting technology is used to deposit titanium dioxide powder layer by layer on the surface of the acid-treated pure titanium to form a porous Titanium dioxide layer, the particle size of the titanium dioxide powder is 50 μm to 100 μm, the vacuum degree of the electron gun is 0.6Mpa, the power is 5.0kW, the accelerating voltage is 30~60kV, the scanning speed is 800mm / min, and the electron beam current is 2.0mA, The thickness of the porous titanium dioxide layer is 0.20mm;

[0035] ②Use isophorone diisocyanate (IPDI) and polycaprolactone 2000 (PCL-2000) as raw materials to prepare polyurethane prepolymer, mix 10g isophorone diisocyanate (IPDI) with 50g polycaprolactone 2000 (PCL -2000) into a thr...

Embodiment 3

[0040] In this embodiment, the process steps for preparing the bionic dental implant are as follows:

[0041] ① The titanium substrate is a bone screw with a diameter of 4.5 mm and a length of 12 mm. The acid treatment of the titanium substrate is the same as in Example 1; electron beam melting technology is used to deposit titanium dioxide powder layer by layer on the surface of the acid-treated titanium substrate to form a porous Titanium dioxide layer, the particle size of the titanium dioxide powder is 50 μm to 100 μm, the vacuum degree of the electron gun is 0.6Mpa, the power is 5.0kW, the accelerating voltage is 30~60kV, the scanning speed is 800mm / min, and the electron beam current is 2.0mA, The thickness of the porous titanium dioxide layer is 0.25mm;

[0042] ②Use isophorone diisocyanate (IPDI) and polytetrahydrofuran ether glycol 1000 (PTMG-1000) as raw materials to prepare polyurethane prepolymer, mix 12g of isophorone diisocyanate (IPDI) with 25g of polytetrahydrof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com