Tissue engineered osteochondral composite stent and preparation method thereof

A technology of tissue engineering bone and composite scaffold, applied in bone implants, medical science, prosthesis, etc., can solve the problem of low proportion of hyaline cartilage, insufficient hydrophilicity and compatibility of osteocartilage scaffold, and weak mechanical properties To achieve the effect of increasing the proportion of hyaline cartilage, improving the hydrophilicity and uniformity of collagen distribution, and increasing the density and depth of cell planting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

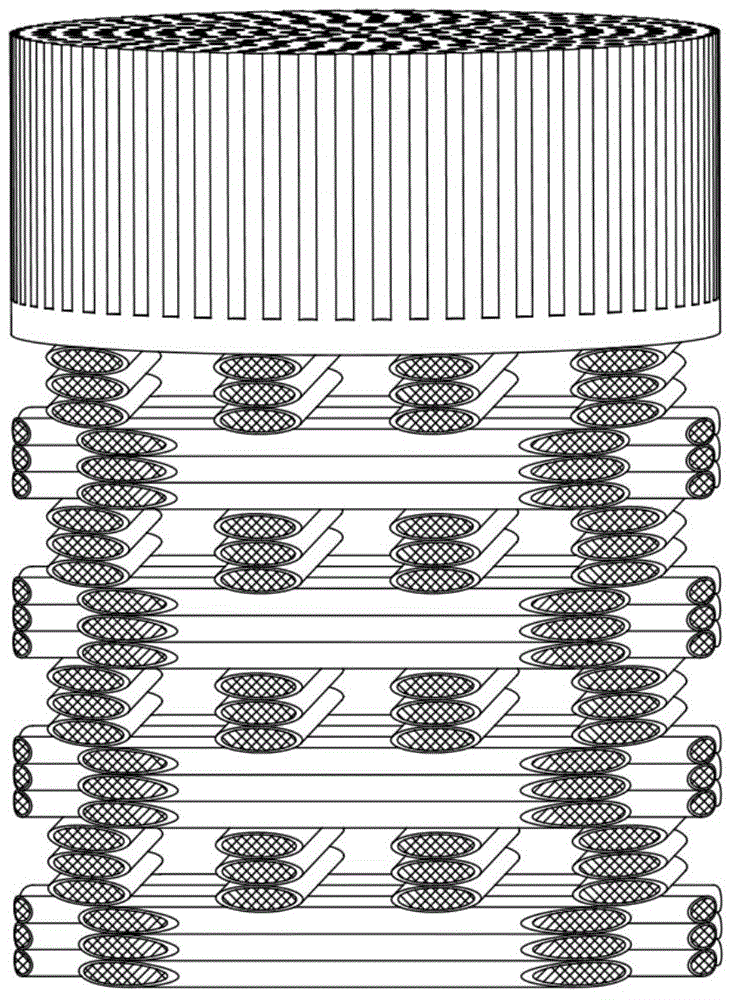

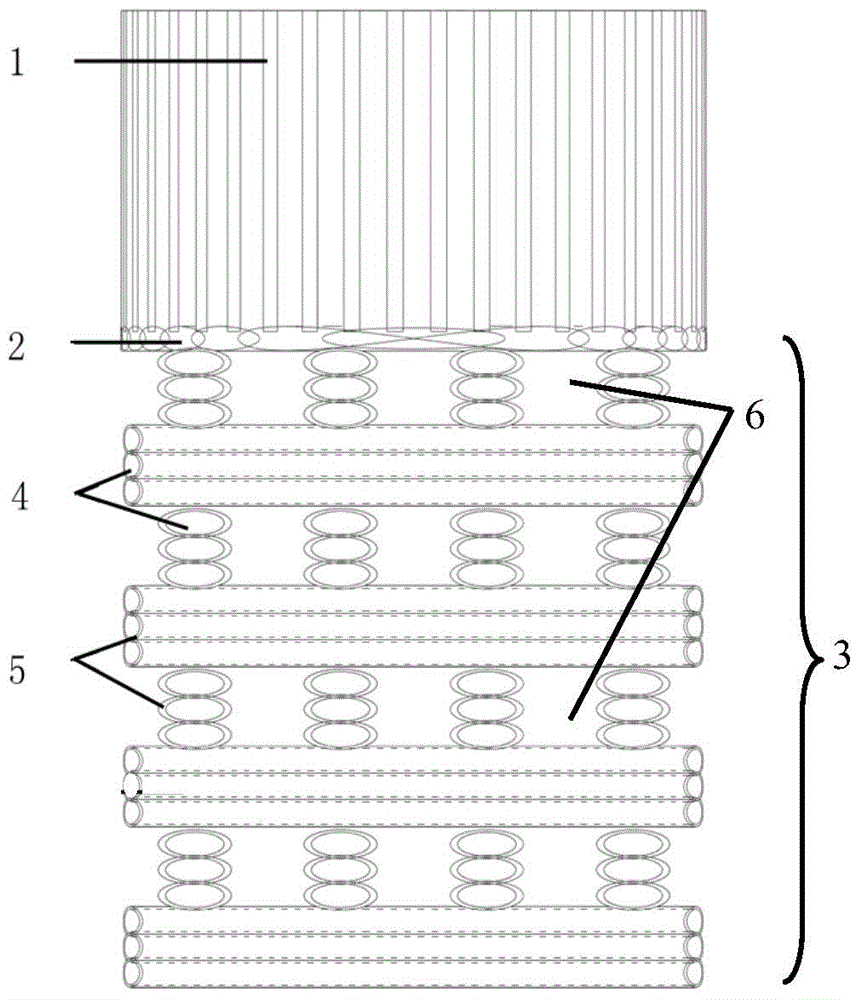

[0046] Example 1: Construction of Tissue Engineering Osteochondral Scaffold

[0047] The cartilage matrix material and chitosan extracted from bovine bone are dissolved in 0.5% acetic acid solution to prepare a cartilage matrix material-chitosan mixed solution with a mass volume concentration of 10mg / ml, and the cartilage matrix material and chitosan in the solution are The mass ratio is 0.5:1. Put the mixed solution into the mold and build a temperature gradient of 10°C / mm in a low temperature environment of -200°C. The mixed solution was solidified and then freeze-dried for 24 hours to obtain a cartilage scaffold with an oriented structure. The scaffold was cross-linked with a genipin solution and adjusted to Neutral, ready for use after freeze-drying. Mix PLGA / tricalcium phosphate at a mass ratio of 5:1 and dissolve in 1,4-dioxane to form a solution with a concentration of 500mg / ml, and dissolve type I collagen in 0.5% acetic acid solution to form a concentration of 2mg C...

Embodiment 2

[0048] Example 2: Construction of Tissue Engineering Osteochondral Scaffold

[0049] The cartilage matrix material and chitosan extracted from bovine bone are dissolved in 3% acetic acid solution to prepare a cartilage matrix material-chitosan mixed solution with a concentration of 50 mg / ml. The mass ratio of cartilage matrix material to sodium alginate in the solution is It is 5:1. Put the mixed solution into the mold and build a temperature gradient of 10°C / mm in a low temperature environment of -80°C. After the mixed solution is solidified and freeze-dried for 24 hours to obtain a cartilage scaffold with an oriented structure, the scaffold is cross-linked and adjusted with sodium polyphosphate solution It is neutral and ready for use after freeze-drying. PLGA / tricalcium phosphate was mixed and dissolved in chloroform at a mass ratio of 10:1 to form a solution with a concentration of 50 mg / ml, and type I collagen was dissolved in 0.5% acetic acid solution to form a collagen...

Embodiment 3

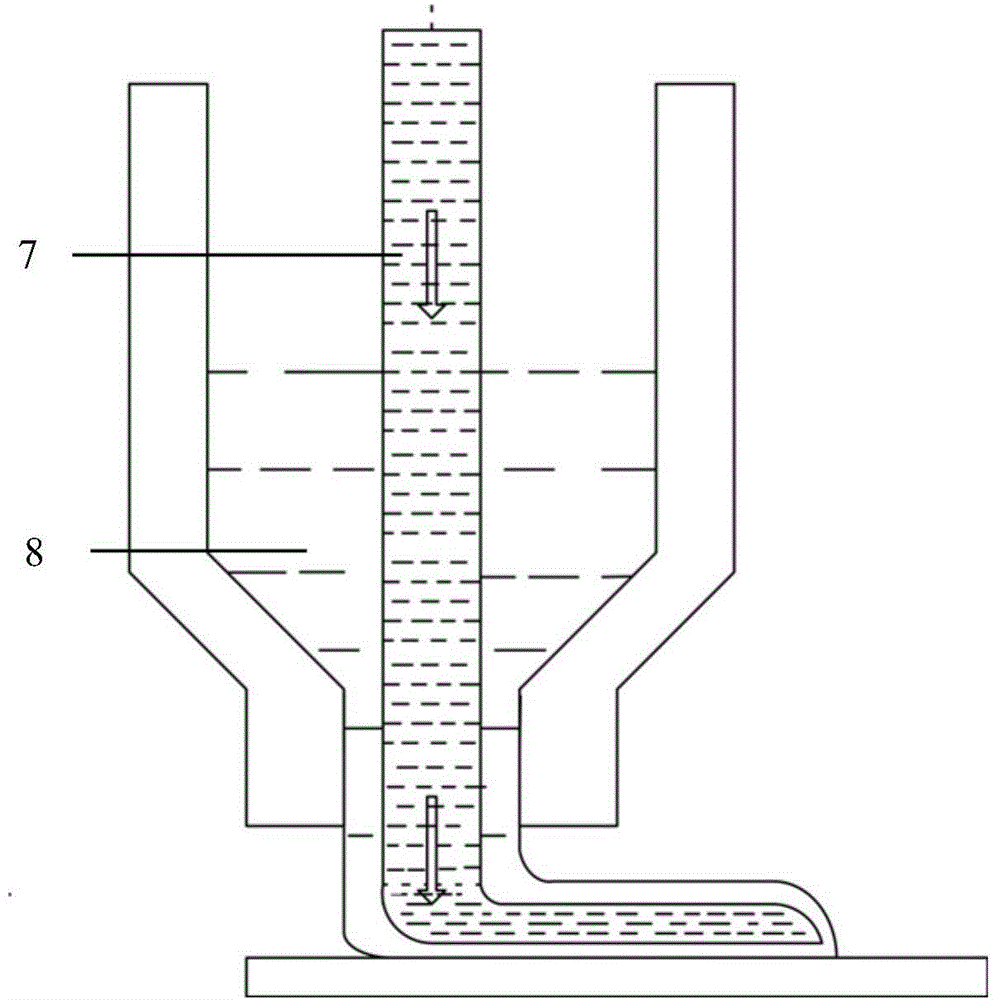

[0050] Example 3: Tissue-engineered osteochondral composite scaffold used for defect repair of rabbit articular cartilage

[0051] The cartilage matrix material and chitosan extracted from bovine bone are dissolved in 0.5% acetic acid solution to prepare a cartilage matrix material-chitosan mixed solution with a concentration of 20 mg / ml, and the mass ratio of cartilage matrix material to gelatin in the solution is 1 :1. Put the mixed solution into the mold and build a temperature gradient of 10°C / mm in a low temperature environment of -200°C. The mixed solution was solidified and then freeze-dried for 24 hours to obtain a cartilage scaffold with an oriented structure. The scaffold was cross-linked with a genipin solution and adjusted to Neutral, ready for use after freeze-drying. Mix PLGA / tricalcium phosphate at a mass ratio of 5:1 and dissolve in 1,4-dioxane to form a solution with a concentration of 200mg / ml, and dissolve type I collagen in 0.5% acetic acid solution to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com