Steel-structure-use nuclear-radiation-resistant paint

A technology of nuclear radiation resistance and steel structure, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of solvent pollution to the marine environment of nuclear power plants, solvent precipitation, etc., and achieve the effects of ensuring service life, improving cleaning, and excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of steel structure anti-nuclear radiation coating of the present invention mainly comprises the following steps:

[0035] a: Weigh epoxy resin, silicone-modified epoxy resin, radiation-resistant filler, diluent, processing aid, curing agent and coupling agent according to the above ratio for later use;

[0036] b: Put epoxy resin, silicone modified epoxy resin, diluent and processing aid in the paint mixing tank, and stir for 2-5 hours at normal temperature and pressure;

[0037] c: Add radiation-resistant fillers to the mixture in step b, and stir for 3-6 hours at normal temperature and pressure until they are evenly mixed;

[0038] d: Grind the mixture in step c through a three-roller machine at normal temperature and pressure until it becomes granular, and the particle size is 20-50 μm;

[0039] e: Add a curing agent to the mixture in step d, and stir for 1-4 hours at normal temperature and pressure;

[0040] f: Add coupling agent to the mixt...

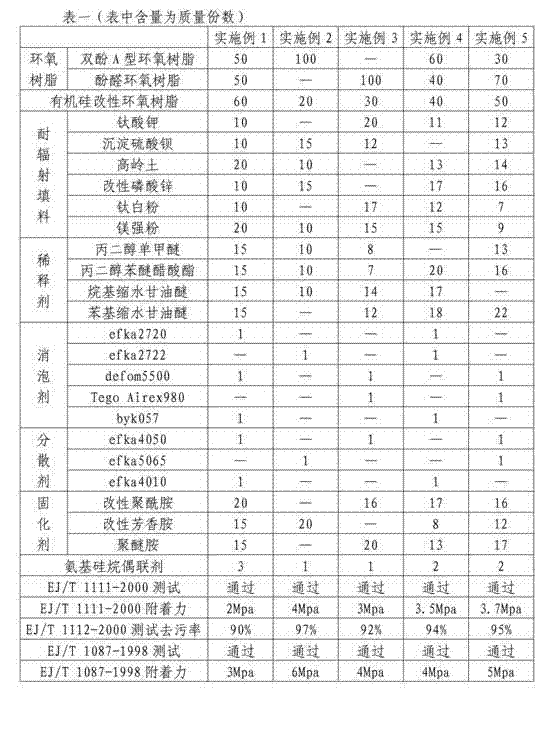

Embodiment 1

[0044] The anti-nuclear radiation coating for steel structures of the invention includes a main agent, a curing agent and a coupling agent, and the main agent includes epoxy resin, silicone modified epoxy resin, radiation-resistant filler, diluent and processing aid. The epoxy resin is a mixture of bisphenol A epoxy resin and novolac epoxy resin; the radiation-resistant filler is a mixture of potassium titanate, precipitated barium sulfate, kaolin, modified zinc phosphate, titanium dioxide, and magnesium powder; the diluent is propylene glycol Monomethyl ether, propylene glycol phenyl ether acetate, alkyl glycidyl ether, phenyl glycidyl ether mixture; processing aids are efka2720, efka4050, efka4010 from Efka in the Netherlands, Deqian defom5500 from Hemings in the United States and Germany A mixture of BYK057 from BYK. The curing agent is a mixture of modified polyamide, modified aromatic amine and polyether amine; while the coupling agent is an aminosilane coupling agent. T...

Embodiment 2

[0054] The anti-nuclear radiation coating for steel structures of the invention includes a main agent, a curing agent and a coupling agent, and the main agent includes epoxy resin, silicone modified epoxy resin, radiation-resistant filler, diluent and processing aid. Among them, the epoxy resin is bisphenol A epoxy resin; the radiation-resistant filler is a mixture of precipitated barium sulfate, kaolin, modified zinc phosphate, and magnesium powder; the diluent is propylene glycol monomethyl ether, propylene glycol phenyl ether acetate, alkyl shrink Glycerin ether mixture; the processing aid is a mixture of efka2722 and efka5065 from Efka Company in the Netherlands. The curing agent adopts modified aromatic amine; while the coupling agent adopts aminosilane coupling agent. The above components are calculated according to mass fraction: 100 parts of bisphenol A epoxy resin; 20 parts of silicone modified epoxy resin; 15 parts of precipitated barium sulfate; 10 parts of kaolin; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com