Clad steel plate for nuclear power engineering and manufacturing method of clad steel plate

A composite steel plate and nuclear power engineering technology, applied in non-electric welding equipment, metal processing equipment, chemical instruments and methods, etc., can solve the problems of high mechanical performance parameters of stainless steel, inability to meet the needs of stainless steel plates, and fewer stainless steel manufacturers, etc., to achieve Save the use of precious metals, reduce imports, and uniform surface corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a method for preparing a composite steel plate, comprising the steps of:

[0054] (1) Surface treatment: Treat the surface of the substrate and doubler board; wherein the treatment described in step (1) is grinding, preferably the surface roughness value Ra of the polished substrate and doubler board is not greater than 7.0 μm, preferably not greater than 6.3 μm.

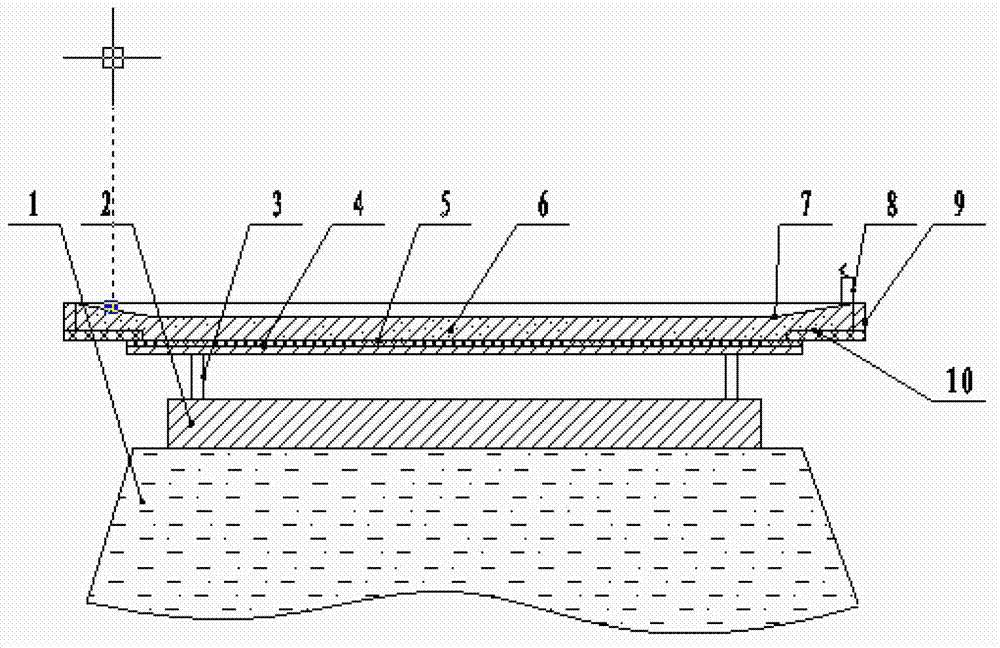

[0055] (2) Explosive welding: carry out explosive welding on the substrate and doubler plate after the treatment in step (1); the explosive velocity used in the explosive welding is 1800m / s-2000m / s, preferably 1850-1950m / s, and the density of the explosive is 0.50g / cm 3 -0.60g / cm 3 , the preferred density is 0.55-0.60g / cm 3 .

[0056](3) Heat treatment: heat the composite steel plate after explosive welding in step (2) at 920-940°C, and then pass in nitrogen gas when the final temperature is 760°C, cool it out of the furnace, and perform high-temperature tempering after...

Embodiment

[0096] The specific composition and content of the various raw materials used in the following examples of the present invention are as follows:

[0097] The surface roughness was measured using a TR210 hand-held roughness meter manufactured by Beijing Shidaizhifeng Technology Co., Ltd.

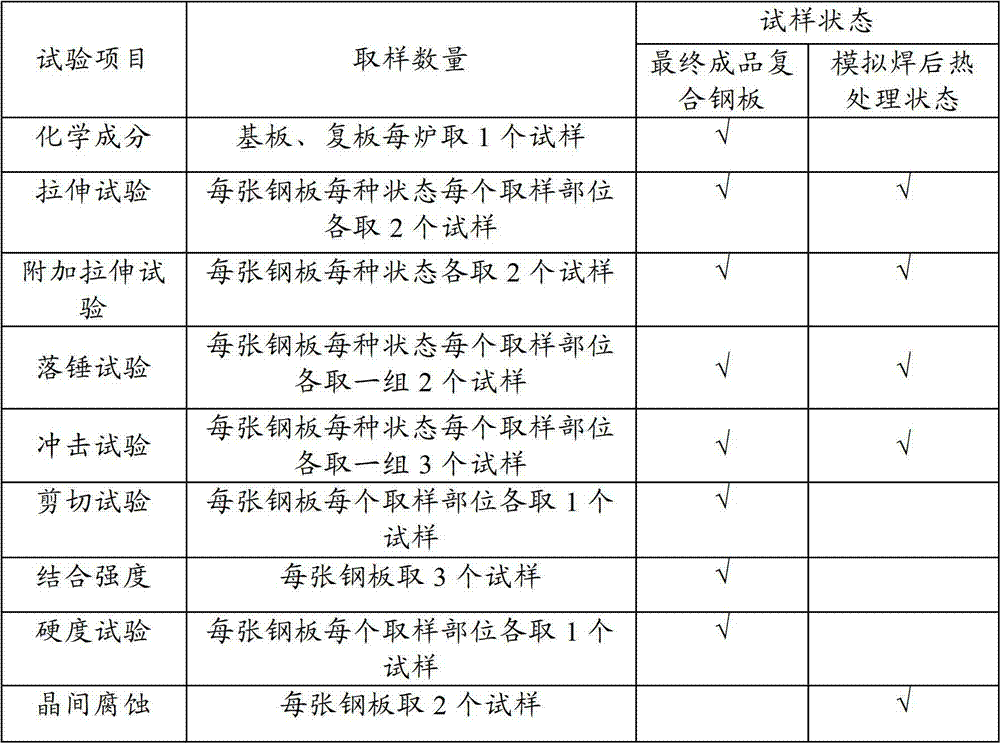

[0098] The sampling method of parameter determination in the embodiment

[0099] 1. Cutting of sample

[0100] Samples are cut from the bottom corners of both ends of the composite steel plate to be tested (except for bonding strength test sampling), and the two samples are located on both sides of the axis of the steel plate. The bond strength test sample is taken from the middle part of the head of the rolled steel plate. The distance from any heat-treated edge of the clad plate shall not be less than the thickness of the clad plate, and the intercepted test specimens shall be appropriately marked and marked with the direction of final rolling. The samples for each sampling location shal...

Embodiment 1

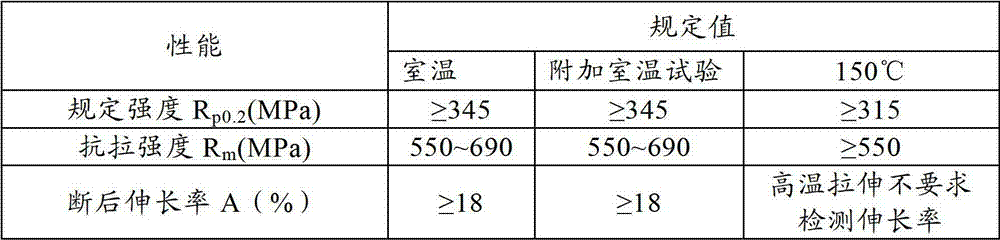

[0148] 1. Matching and detection

[0149] Compare the length-to-width ratio of the base plate and double plate whose composition is shown in Table 4, and the dimensions of the selected base plate and double plate are as follows:

[0150] Substrate: SA533 B CL.1 steel plate in SA-533 / SA-533M. Length 10050mm; width 1500mm; thickness 20mm;

[0151] Double plate: SA240 304L (Z2CN18-10) stainless steel in ASTM SA240. Length 10150mm; width 1580mm; thickness 3mm.

[0152] Conduct non-destructive testing on the base plate and double plate of the clad steel plate used above, and conduct 100% volume ultrasonic testing on the base plate steel plate of the clad steel plate according to the testing method and acceptance standard of ASME Volume V non-destructive testing, and the test result is no crack, fold , slag inclusion and other rolling defects; X-ray inspection and penetrant inspection are carried out on the cladding plate of the clad steel plate, and the inspection results show t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com