Method for preparing manganese phosphate lithium / carbon composite material

A technology of carbon composite materials and lithium manganese iron phosphate, which is applied in the field of materials science, can solve the problems of difficulty in improving and solving the yield rate of battery factories, difficulty in ensuring product batches, and difficulty in industrialization, and achieve good cycle stability. , reduce equipment investment and production costs, and shorten working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

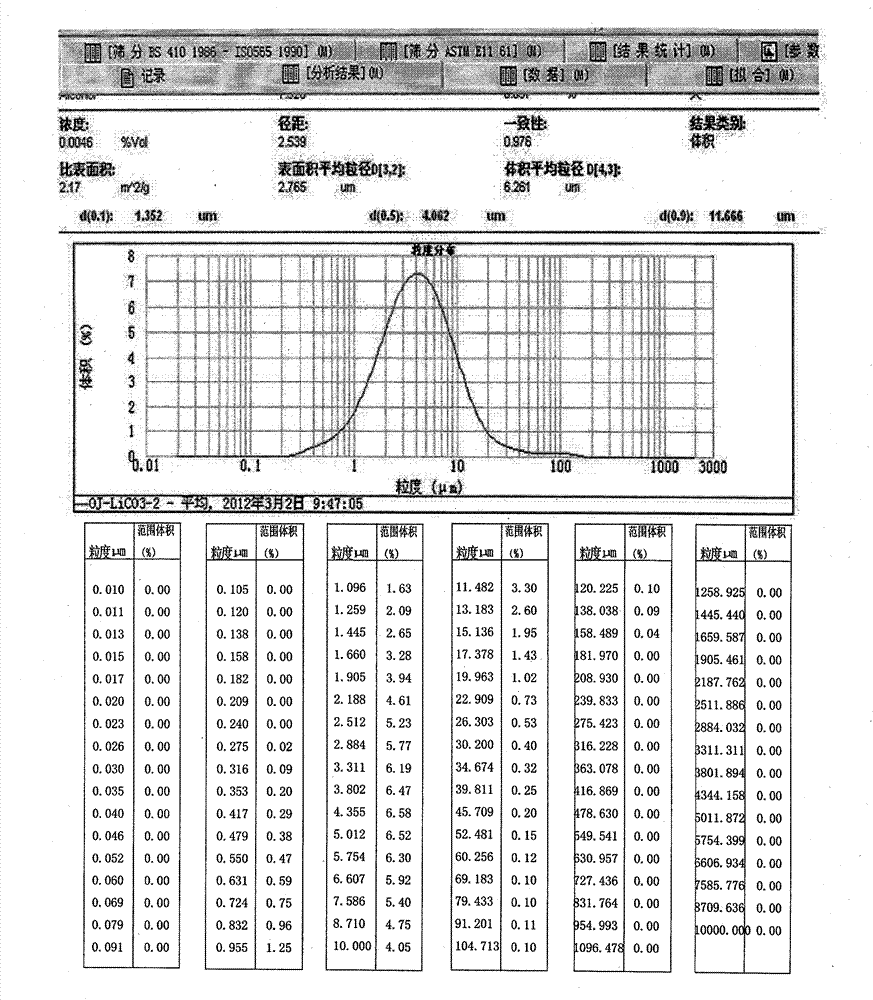

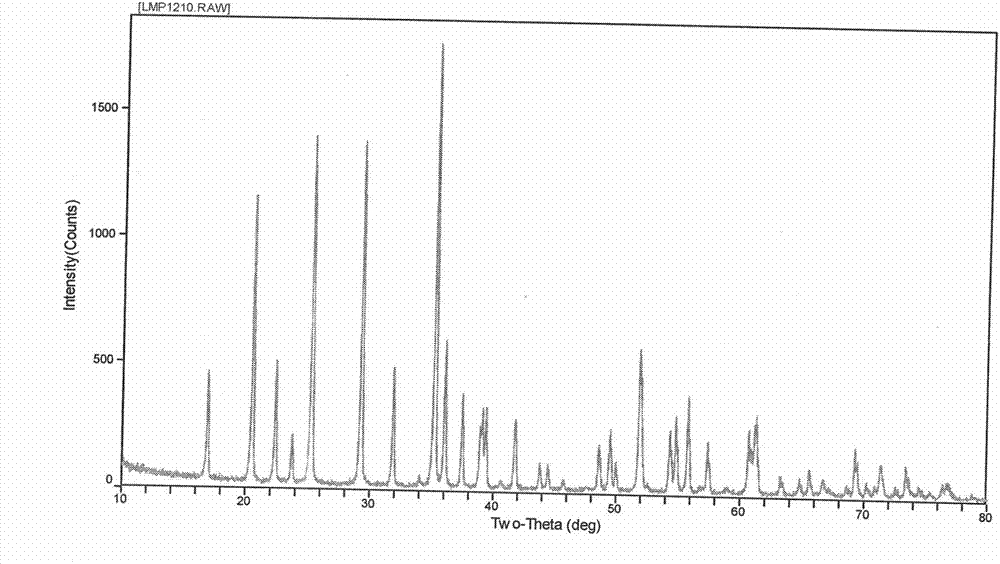

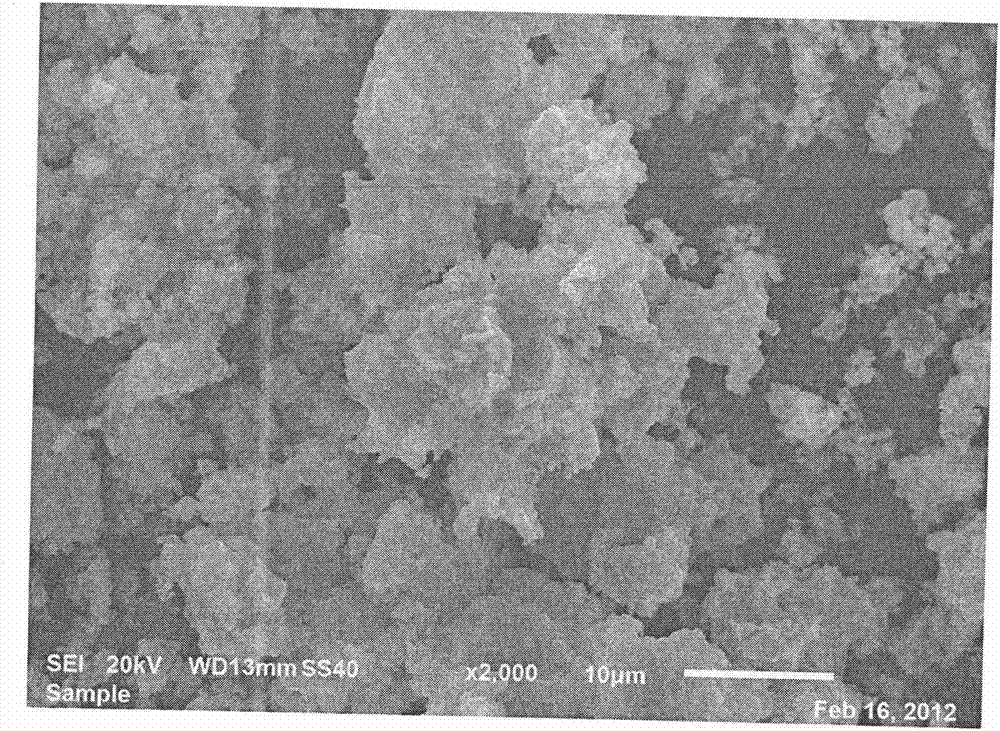

Embodiment 1

[0021] At room temperature, take lithium carbonate 16.3284g (battery grade 99.5%), glucose powder 19.7562g (food grade), manganese monoxide 24.0000g (high purity), ammonium dihydrogen phosphate 51.1024g (food grade), ferrous oxalate 15.1390 g (battery grade), 1.3501g of magnesium hydroxide (nano-grade), 150ml of absolute ethanol as a dispersant, added to a 500ml stainless steel ball mill tank, added 200g of zirconium balls, and ball milled at a speed of 300r / min for 4 Hours, then dry in a protective oven with 99.99% nitrogen at a drying temperature of 60-80°C. After drying, use a high-speed pulverizer to pulverize it, and then place it in a tube furnace with 99.99% nitrogen as the sintering atmosphere , the gas flow rate is 6L / min, and the furnace temperature is raised to 660°C at a heating rate of 3°C / min, and then sintered at 660°C for 6 hours. After cooling to room temperature, it passes through a 300 mesh screen to obtain lithium manganese phosphate Carbon composite materi...

Embodiment 2

[0023] At room temperature, take lithium carbonate 16.3284g (battery grade 99.5%), glucose powder 9.8780g (food grade), manganese monoxide 24.0000g (high purity), ammonium dihydrogen phosphate 51.1024g (food grade), ferrous oxalate 15.1390 g (battery grade), 1.3501g of magnesium hydroxide (nano-grade), 150ml of absolute ethanol as a dispersant, added to a 500ml stainless steel ball mill tank, added 200g of zirconium balls, and ball milled at a speed of 300r / min for 4 Hours, then dry in a protective oven with 99.99% nitrogen at a drying temperature of 60-80°C. After drying, use a high-speed pulverizer to pulverize it, and then place it in a tube furnace with 99.99% nitrogen as the sintering atmosphere , the gas flow rate is 6L / min, and the furnace temperature is raised to 550°C at a heating rate of 3°C / min, and then sintered at 660°C for 6 hours. After cooling to room temperature, it passes through a 300-mesh screen to obtain lithium iron manganese phosphate Carbon composite ma...

Embodiment 3

[0025] At room temperature, take lithium carbonate 16.3284g (battery grade 99.5%), glucose powder 9.8780g (food grade), manganese monoxide 26.0000g (high purity), ammonium dihydrogen phosphate 51.1024g (food grade), ferrous oxalate 10.0920 g (battery grade), 1.3501g of magnesium hydroxide (nano-grade), 150ml of absolute ethanol as a dispersant, added to a 500ml stainless steel ball mill tank, added 200g of zirconium balls, and ball milled at a speed of 300r / min for 4 Hours, then dry in a protective oven with 99.99% nitrogen at a drying temperature of 60-80°C. After drying, use a high-speed pulverizer to pulverize it, and then place it in a tube furnace with 99.99% nitrogen as the sintering atmosphere , the gas flow rate is 6L / min, and the furnace temperature is raised to 550°C at a heating rate of 3°C / min, and then sintered at 660°C for 6 hours. After cooling to room temperature, it passes through a 300-mesh screen to obtain lithium iron manganese phosphate Carbon composite ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com