Special cable for buggy ladle

A special cable and ladle car technology, which is applied in the direction of insulated cables, textile cables, cables, etc., can solve the problems of low acid and alkali corrosion resistance, harsh cable use environment, easy aging and deterioration, etc., to achieve excellent electrical and mechanical properties, Avoid conductor short-circuit phenomenon and improve atmospheric aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

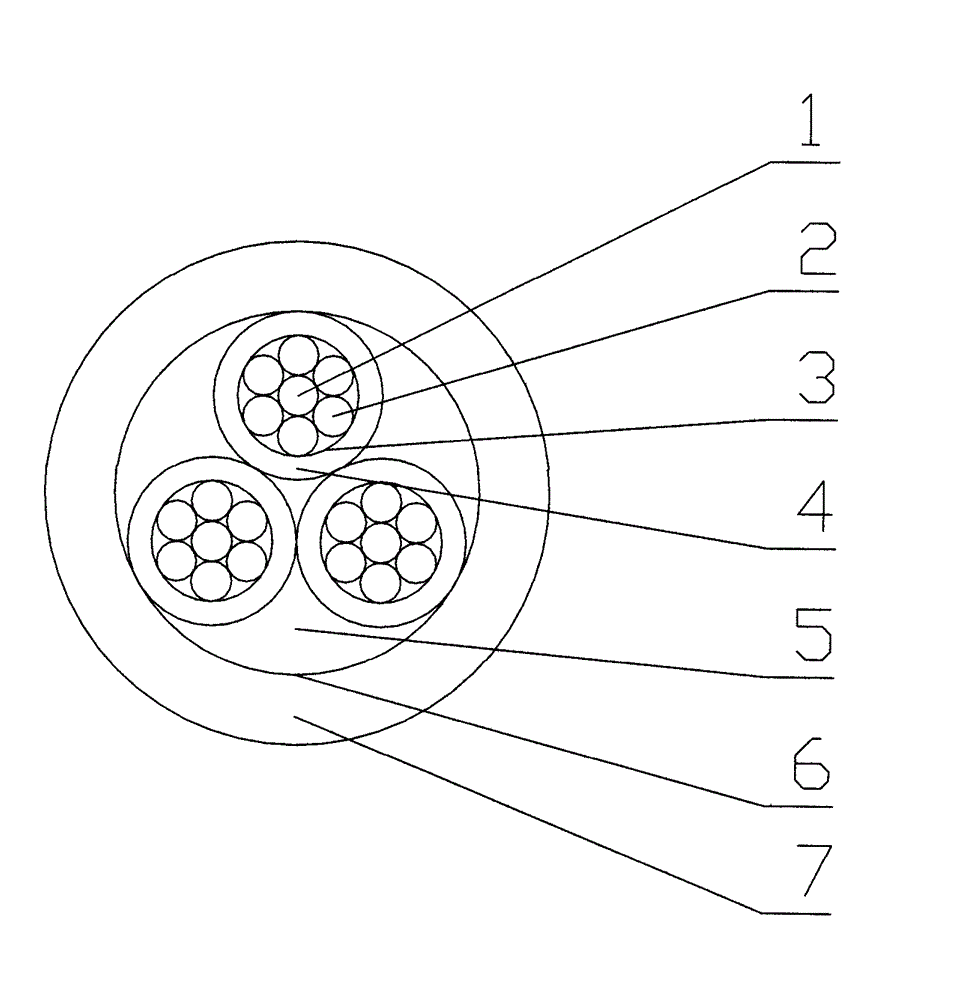

[0030] Next, the special cable for ladle car of the present invention will be described in detail below with reference to the accompanying drawings.

[0031] The special cable for ladle cars, its structure includes an outer protective sheath and a conductor core inside the protective sheath; the conductor core is composed of a tension-strengthening inner core in the middle and a copper wire core twisted around the inner core and its periphery. The tensile strength reinforced inner core is made of carbon fiber or galvanized stranded steel core. The protective sheath is a silicone rubber sheath, a silicon rubber insulating layer is provided outside the entire conductor core, and inorganic fillers are filled between the silicon rubber sheath and the silicon rubber insulating layer. The outer peripheral side of the conductor core between the entire conductor core and the silicone rubber insulating layer is wrapped with a double-sided synthetic refractory mica tape; Wrapped with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com