Near-infrared-luminescence bismuth-doped barium chloropentaborate crystal and preparation method thereof

A technology of barium chloropentaborate and crystal, which is applied in the field of bismuth-doped barium chloropentaborate crystal and its preparation with near-infrared light emission, and can solve the problems of insufficient fluorescence bandwidth and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

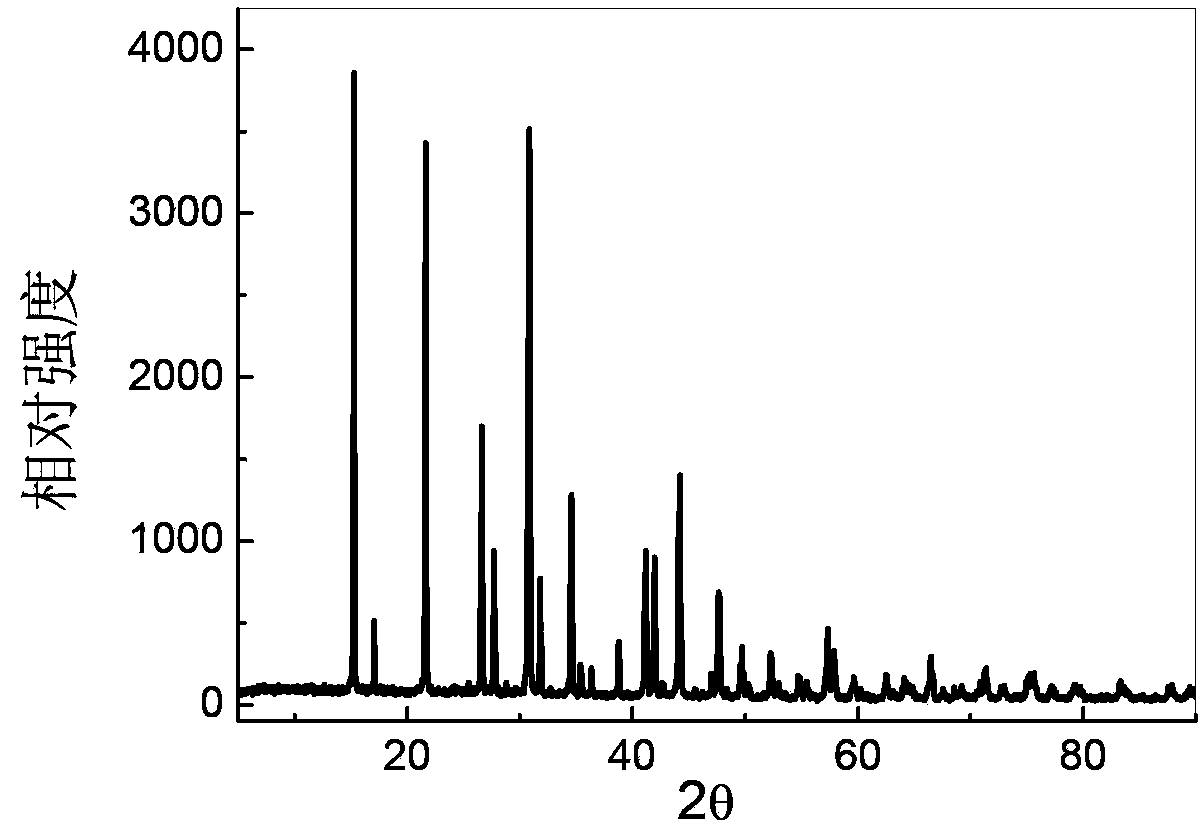

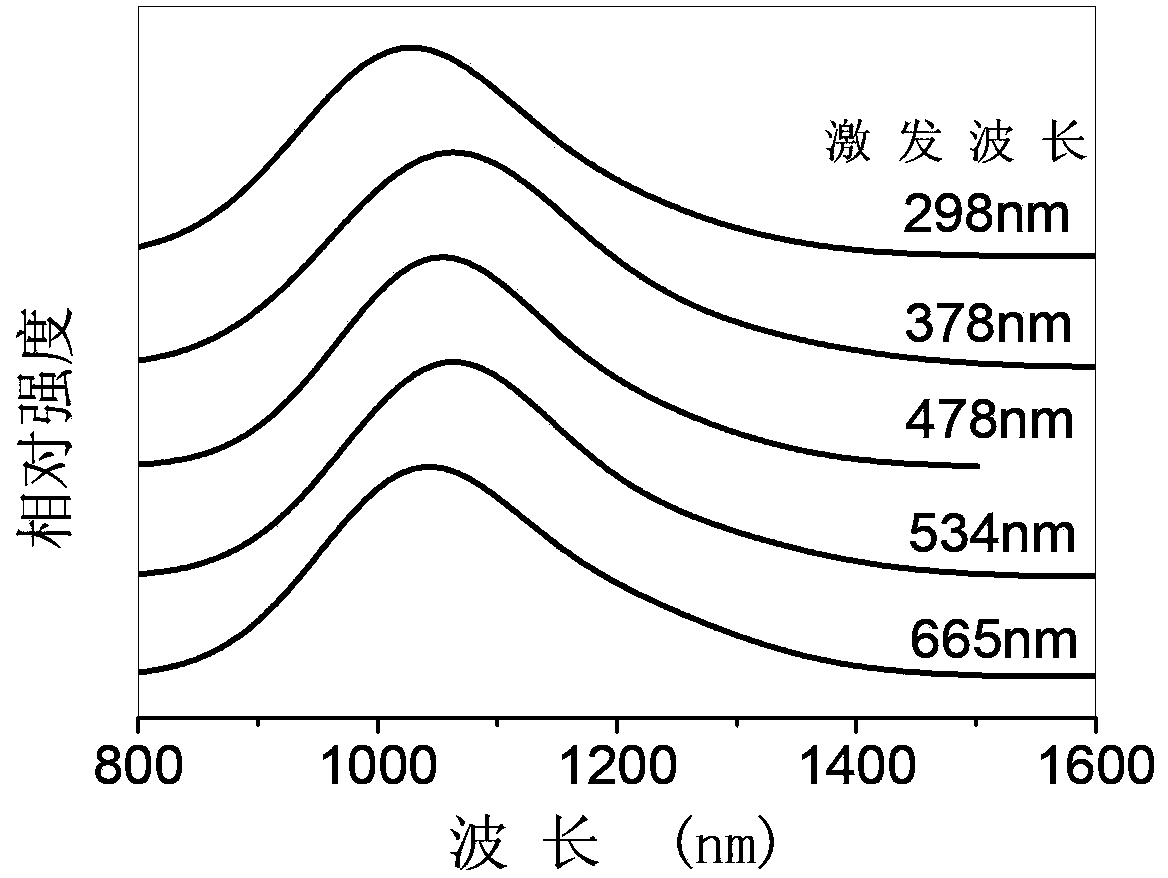

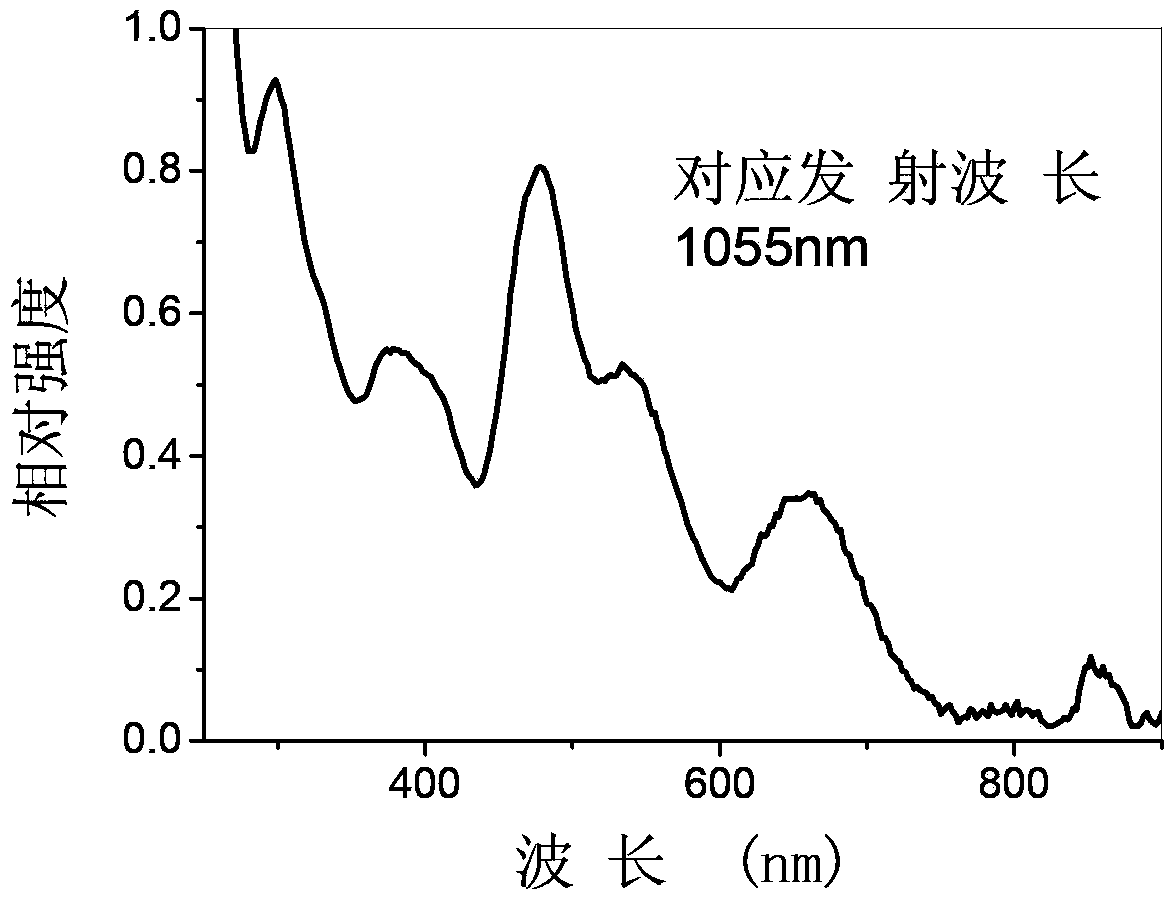

[0032] Example 1—Preparation of bismuth-doped barium chlorinated pentaborate crystals by high-temperature solid-state method

[0033] Choose barium carbonate, boric acid, barium chloride and bismuth trioxide as starting materials, press Ba 2(1-x) B 5 o 9The molar ratio indicated by Cl:2xBi (x=0.05), that is, Ba:B:Cl:Bi=1.90:5:1:0.10, weighed four kinds of raw materials respectively, and controlled the total weight of the mixture to be 50 grams. After mixing, the mixture is put into a corundum crucible, and then the crucible is put into a high-temperature electric furnace. Control the heating rate to 0.83C / min, control the decomposition rate of boric acid, prevent the mixture from overflowing from the crucible, and pre-fire the sample at 500C for 10 hours. Take out the pre-fired sample, grind and mix it again, put it into a crucible, burn it at 1000C for 10 hours twice, and grind it again in the middle. The fired sample was placed at 1000C, H 2 After 15 minutes of treatmen...

Embodiment 2

[0039] Example 2—Preparation of bismuth-doped barium chloropentaborate crystals by high-temperature solid-state method

[0040] Choose barium hydroxide, diboron trioxide, ammonium chloride and bismuth trioxide as starting raw materials, press Ba 2(1-x) B 5 o 9 The molar ratio shown by Cl:2xBi(x=0.0001), that is, Ba:B:Cl:Bi=1.9998:5:1:0.0002, weighed four kinds of raw materials respectively, and controlled the total weight of the mixture to be 50 grams. After the mixture is mixed, put it into a corundum crucible, and then put the crucible into a high-temperature electric furnace. Control the heating rate to 3C / min, control the decomposition rate of diboron trioxide and ammonium chloride to prevent the mixture from overflowing from the crucible, and pre-fire the sample at 400oC for 10 hours. Take out the pre-fired sample, grind and mix it again, put it into a crucible, burn it at 800oC for 10 hours twice, and grind it again in the middle. The fired sample is placed at 800oC,...

Embodiment 3

[0041] Example 3—Preparation of bismuth-doped barium chlorinated pentaborate crystals by high-temperature solid-state method

[0042] Choose barium oxide, metaboric acid, barium chloride and bismuth powder as starting materials, press Ba 2(1-x) B 5 o 9 The molar ratio indicated by Cl:2xBi (x=0.10), namely Ba:B:Cl:Bi=1.80:5:1:0.20, weighed four kinds of raw materials respectively, and controlled the total weight of the mixture to be 50 grams. After the mixture is mixed, put it into a corundum crucible, and then put the crucible into a high-temperature electric furnace. Control the heating rate to 0.4C / min, control the metaboric acid decomposition rate, prevent the mixture from overflowing from the crucible, and pre-fire the sample at 750C for 5 hours. Take out the pre-fired sample, grind and mix it again, put it into a crucible, burn it at 900C for 5 hours twice, and grind it again in the middle. The fired sample is placed in 900CN 2 +H 2 Treated in the atmosphere for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence lifetime | aaaaa | aaaaa |

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com