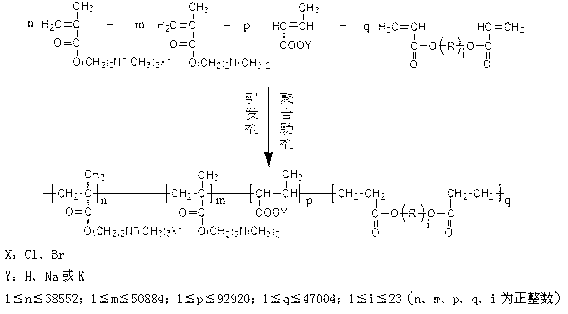

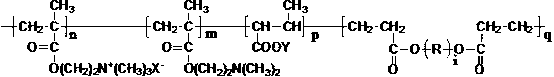

Water-solubility organic amphoteric polymeric flocculant and preparation method thereof

An amphoteric polymer and water-soluble technology, which is applied in flocculation/precipitation water/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of non-compliance with green chemistry and low storage stability, and is suitable for promotion Application, obvious economic benefit, effect of reducing residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Step 1, step 1, add a mixture of 3g of crotonic acid (salt), 0.006g of polymerization assistant sodium edetate and potassium fluoride into a 250mL four-necked reaction flask equipped with a thermometer, a nitrogen device and a stirrer Stir and dissolve with 17g of distilled water, vacuumize twice, each time for 5 minutes, and pass nitrogen once in the middle, for 5 minutes;

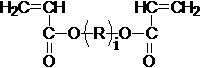

[0052] Step 2. Dilute 16g of methacryloyloxyethyltrimethylammonium halide with 2g of distilled water and put it into the dropping funnel (a), add 2g of bifunctional mono Bulk diacrylate was diluted with 14g of distilled water and mixed evenly into the dropping funnel (b);

[0053] Step 3, under the condition of continuous stirring and nitrogen passage, add the mixture of 0.2g redox initiator potassium persulfate and sodium bisulfite at one time, the ratio of the amount of oxidizing agent to reducing agent is 1: 0.6, and the temperature is raised to 35 ℃, adjust the pH of the aqueous solution to 4,...

Embodiment 2

[0056] Step 1, step 1, add 4.5g of crotonic acid (salt), 0.008g of polymerization assistant sodium edetate and potassium fluoride in a 250mL four-necked reaction flask equipped with a thermometer, a nitrogen device and a stirrer Stir the mixture and 25g of distilled water to dissolve, vacuumize twice for 5 minutes each time, and pass nitrogen once in the middle for 5 minutes;

[0057] Step 2. Dilute 24g of methacryloyloxyethyltrimethylammonium halide with 3g of distilled water and put it into the dropping funnel (a), add 3g of bifunctional group to 4.5g of N,N-dimethylaminoethyl methacrylate Monomer diacrylate is diluted with 21g of distilled water and mixed evenly into the dropping funnel (b);

[0058] Step 3, under the condition of continuous stirring and nitrogen flow, add the mixture of 0.3g redox initiator potassium persulfate and sodium bisulfite at one time, the ratio of the amount of oxidizing agent to reducing agent is 1: 0.5, and the temperature is raised to 35 ℃, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com