Method for producing casing pipe for thickened oil thermal production well

A technology for thermal recovery of heavy oil and thermal recovery wells, which is applied in the direction of casing, drill pipe, earthwork drilling and production, etc., which can solve the problems of high price, increased oil field production cost, low plastic strain and allowable strain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

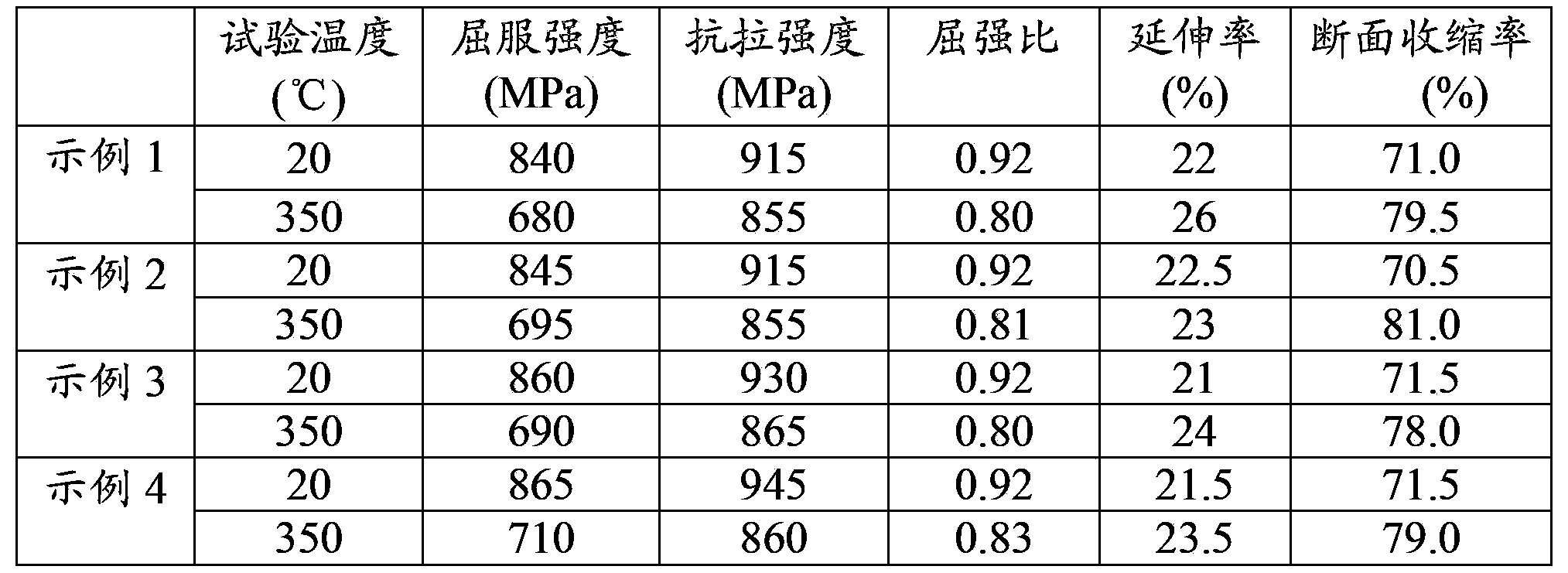

Examples

Embodiment Construction

[0008] The method for manufacturing casings for heavy oil thermal recovery wells provided by the present invention comprises the following steps: steelmaking and continuous casting, steelmaking includes primary molten steel, deoxidation alloying and refining, in primary molten steel, controlling the Carbon is not less than 0.06% by weight and phosphorus is not more than 0.003% by weight, and the tapping temperature range is controlled to be 1620°C to 1660°C. During refining, BaSiAlCa deoxidizer or Ca-based deoxidizer is added at 2.5 to 3.5kg / t, and Add Al block at 1.0kg / t for deoxidation alloying. After refining, feed Ca-Si wire at 0.6~0.8kg / t outside the furnace, and control the intensity of argon blowing to keep the molten steel peristaltic and the molten steel must not be exposed. Control the net blowing time ≥ 12 minutes to obtain Cr-Mn steel. The chemical composition of the steel is: carbon: 0.24% to 0.30%, silicon: 0.15% to 0.40%, manganese: 0.8% to 1.2%, Chromium: 0.9% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com