Magnetic conductive material for electromagnetic relay and preparation method thereof

A technology of electromagnetic relays and magnetic materials, which is applied in the field of metallurgy, can solve the problems of inability to meet the requirements of electromagnetic relays, unstable coercive force of magnetic materials, and poor comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] Example of the present invention provides a kind of preparation method of the magnetic conduction material that electromagnetic relay is used, comprises the steps:

[0021] S01. Choose CH1T material as the base material;

[0022] S02. Perform drawing treatment on the base material, wherein the total compression rate of drawing is ≥80%, and the partial compression rate is ≤10%, to obtain a preformed wire;

[0023] S03. Perform cold heading forming treatment and recrystallization annealing treatment on the preformed wire, wherein the temperature of the recrystallization annealing treatment is 850-900° C., and the treatment time is 4-6 hours.

[0024] Specifically, in the above step S01, the CH1T material is selected as the base material. The material belongs to industrial pure iron. The product has the advantages of stable composition, low harmful elements, high steel purity, high surface quality, high geometric precision, and good electromagnetic performance. At the sam...

Embodiment 1

[0038] The CH1T material is selected as the base material, and the total weight of the base material is 100%, including the following element components in the following weight percentages: C content is 0.005%; P content is 0.020%; S content is 0.020%; Ti content is 0.06%; the shape of the selected base metal is elliptical, and the ellipticity is 0.10mm; the grain size is 8 grades, and the non-metallic inclusions are 0.5 grades.

[0039]The preparation method comprises the following steps: selecting the above-mentioned CH1T material as the base material; drawing the base material, wherein the total compression rate of drawing is 80%, the partial compression rate is 6%, and the wire drawing speed is 10m / s, and the obtained Preformed wire rod: cold heading forming treatment is performed on the preformed wire rod, the cold heading speed is 150 per minute, and then recrystallization annealing treatment is performed, and the annealing treatment is carried out in a methanol atmospher...

Embodiment 2

[0041] The CH1T material is selected as the base material, and the total weight of the base material is 100%, including the following element components in the following weight percentages: C content is 0.008%; P content is 0.010%; S content is 0.010%; Ti content is 0.08%; the shape of the selected base metal is ellipse, and the ellipticity is 0.08mm; the grain size is 9 grades, and the non-metallic inclusions are 0.4 grades.

[0042] The preparation method includes the following steps: selecting the above-mentioned CH1T material as the base material; drawing the base material, wherein the total compression rate of drawing is 85%, the partial compression rate is 8%, and the wire drawing speed is 11m / s, and the obtained Preformed wire rod: cold heading forming treatment is carried out on the preformed wire rod, the cold heading speed is 180 per minute, and then recrystallization annealing treatment is carried out, and the annealing treatment is carried out in a methanol atmosphe...

PUM

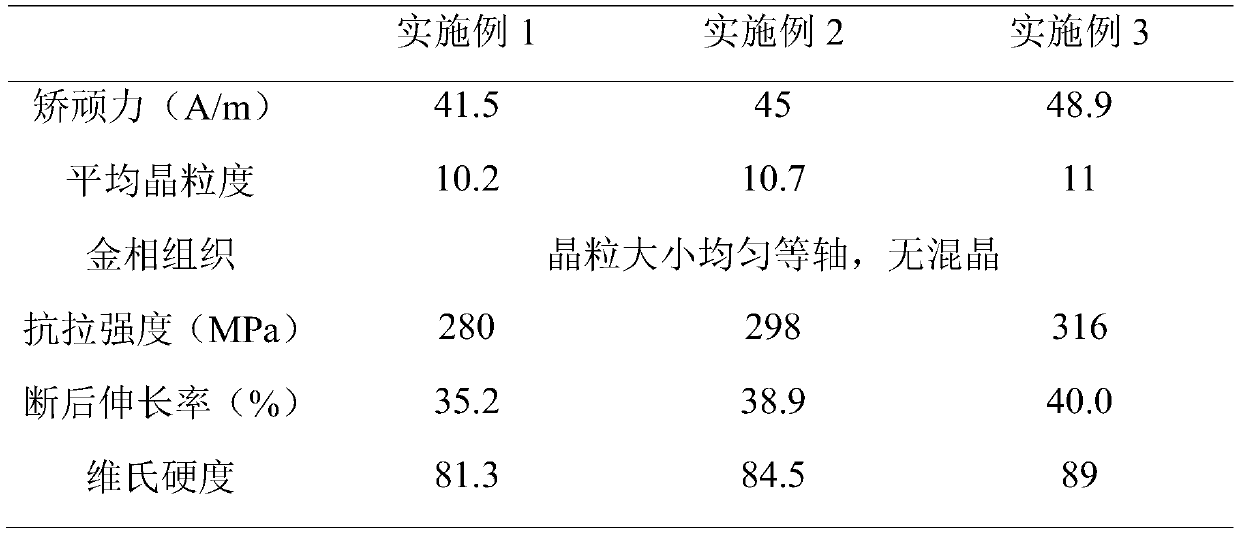

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com