A chain stainless steel for food and its preparation method

A stainless steel and chain technology, applied in the field of food chain stainless steel and its preparation, can solve the problems of high price and increased use cost, and achieve the effect of low cost and high steel purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment 1 discloses a stainless steel chain for food, which consists of the following chemical components in terms of mass percentage: C: 0.04-0.07%; Si: 0.5-1.0%; Mn: 0.5-1.0%; Cr: 14.0-14.5% ; Ni: 1.3-1.7%; S: <0.002%; P: <0.025%; Ti: 0.3-0.5%; Mo: 0.2-0.4%; the balance is Fe and unavoidable impurities.

[0029] This embodiment 1 also discloses a method for preparing stainless steel chains for food. The preparation method adopts the technological process of "electric furnace-AOD-LF-continuous casting-hot rolling-solution pickling".

[0030] The concrete steps of the preparation method of food chain stainless steel are as follows:

[0031] The first step: the electric furnace uses scrap steel and ferronickel as raw materials for batching. During smelting, foam slag is formed and slag is flowed, and the slag is replaced. The end point of molten steel is C>1%, P<0.02%, and 100% of the steel is blocked from slag;

[0032] Step 2: In the AOD furnace, decarburize b...

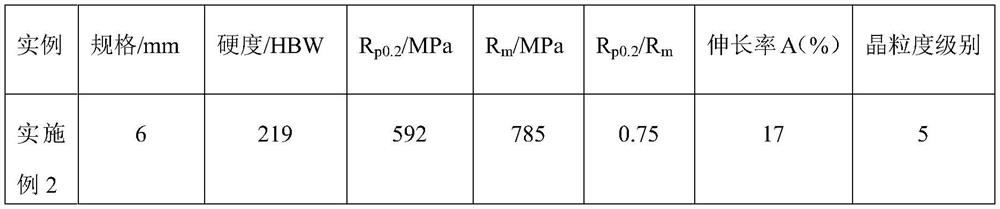

Embodiment 2

[0046] This embodiment 2 discloses a chain stainless steel for food, which consists of the following chemical components in terms of mass percentage: C: 0.056%; Si: 0.62%; Mn: 0.61%; Cr: 14.33%; Ni: 1.45%; S: 0.0017 %; P: 0.021%; Ti: 0.38%; Mo: 0.2%; the balance is Fe and unavoidable impurities.

[0047] The preparation method of this chain stainless steel for food is:

[0048] The first step: the electric furnace uses steel scrap and ferronickel as raw materials for batching. During smelting, foamy slag is formed, slag is flowed, and slag is replaced. The end point of molten steel is C=1.7%, P=0.013%, and 100% of the steel is blocked from slag;

[0049] Step 2: In the AOD furnace, decarburize by blowing oxygen from the side and top of the furnace, denitrify by blowing argon from the side all the way, decarburize in stages, and add high-carbon ferrochromium, ferromanganese, and silicon in batches during the blowing process Alloying iron and other alloys, adding lime, fluorite...

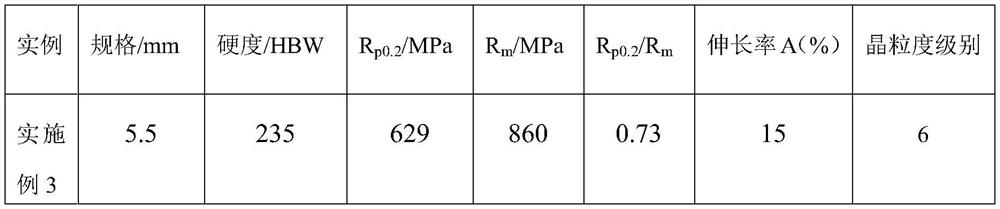

Embodiment 3

[0057] A stainless steel chain for food is disclosed in Example 3, which consists of the following chemical components in terms of mass percentage: C: 0.068%; Si: 0.72%; Mn: 0.66%; Cr: 14.25%; Ni: 1.40%; S: 0.0014%; P: 0.019%; Ti: 0.36%; Mo: 0.31%; the balance is Fe and unavoidable impurities.

[0058] The preparation method of this chain stainless steel for food is:

[0059] The first step: the electric furnace uses steel scrap and ferronickel as raw materials for batching. During smelting, foamy slag is formed, slag is flowed, and slag is replaced. The end point of molten steel is C = 2.03%, P = 0.010%, and 100% of the steel is blocked from slag;

[0060] Step 2: In the AOD furnace, oxygen decarburization is re-blown from the side and top of the furnace, argon is blown from the whole side to denitrify, decarburization is carried out in stages, and high-carbon ferrochromium, ferromanganese, and silicon are added in batches during the blowing process Alloying iron and other a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com