Production method of -195℃ ultra-low temperature seamless steel pipe billet steel

A technology of seamless steel pipe and production method, applied in the field of metallurgy, can solve the problems of inability to solve the tube blank, long production cycle, poor competitiveness, etc., and achieves the effects of low cost, short production process and reduced product production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

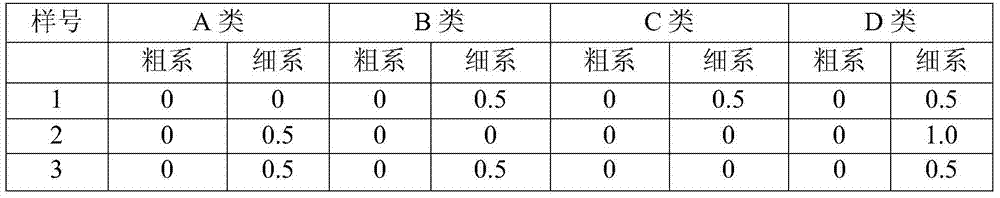

Embodiment 1-3

[0033] Production process: through high-impedance ultra-high-power electric arc furnace → LF refining furnace → VD vacuum treatment → round billet continuous casting;

[0034] (1) The electric furnace uses scrap steel and pig iron as raw materials, of which scrap steel accounts for 60-70%, and pig iron accounts for 30-40%. , high iron oxide, and the violent stirring of the furnace wall cluster oxygen lance blowing oxygen decarburization, etc., effectively remove the harmful elements phosphorus, hydrogen, nitrogen gas and non-metallic inclusions in the molten steel; control the end carbon of the electric arc furnace molten steel ≤0.02% and phosphorus ≤0.002%, add Al balls and CaBaAlSi for pre-deoxidation during the tapping process of the electric furnace, control the Al content of molten steel to 0.09-1.4%, and add 25-30% of the total amount of the alloy to Ni plates for alloying. The tapping temperature of the electric arc furnace is 1650-1670°C, and the eccentric bottom tappi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com