Device and method for processing glass sheet material

A processing device and processing method technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of broken glass sheet, broken glass sheet, damaged strength of strengthened glass, etc., to save processing and manufacturing costs, The effect of saving man-hours and costs and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

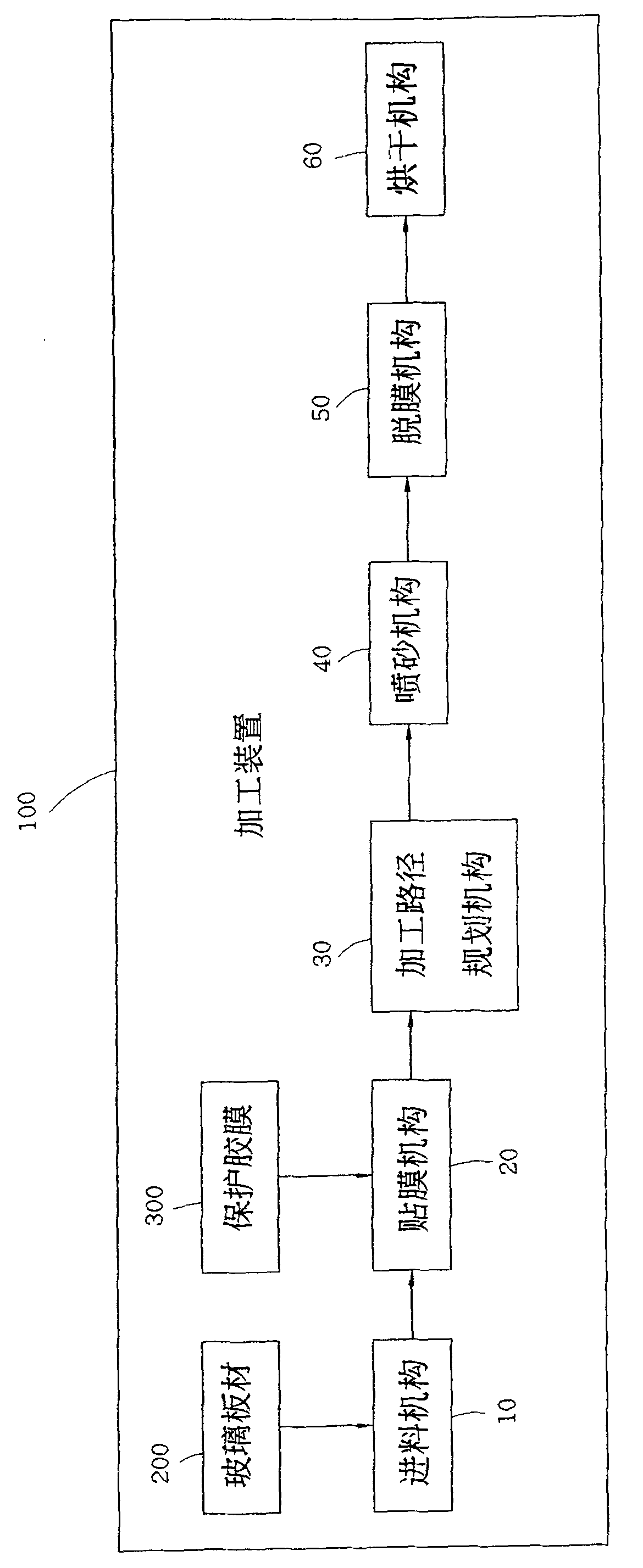

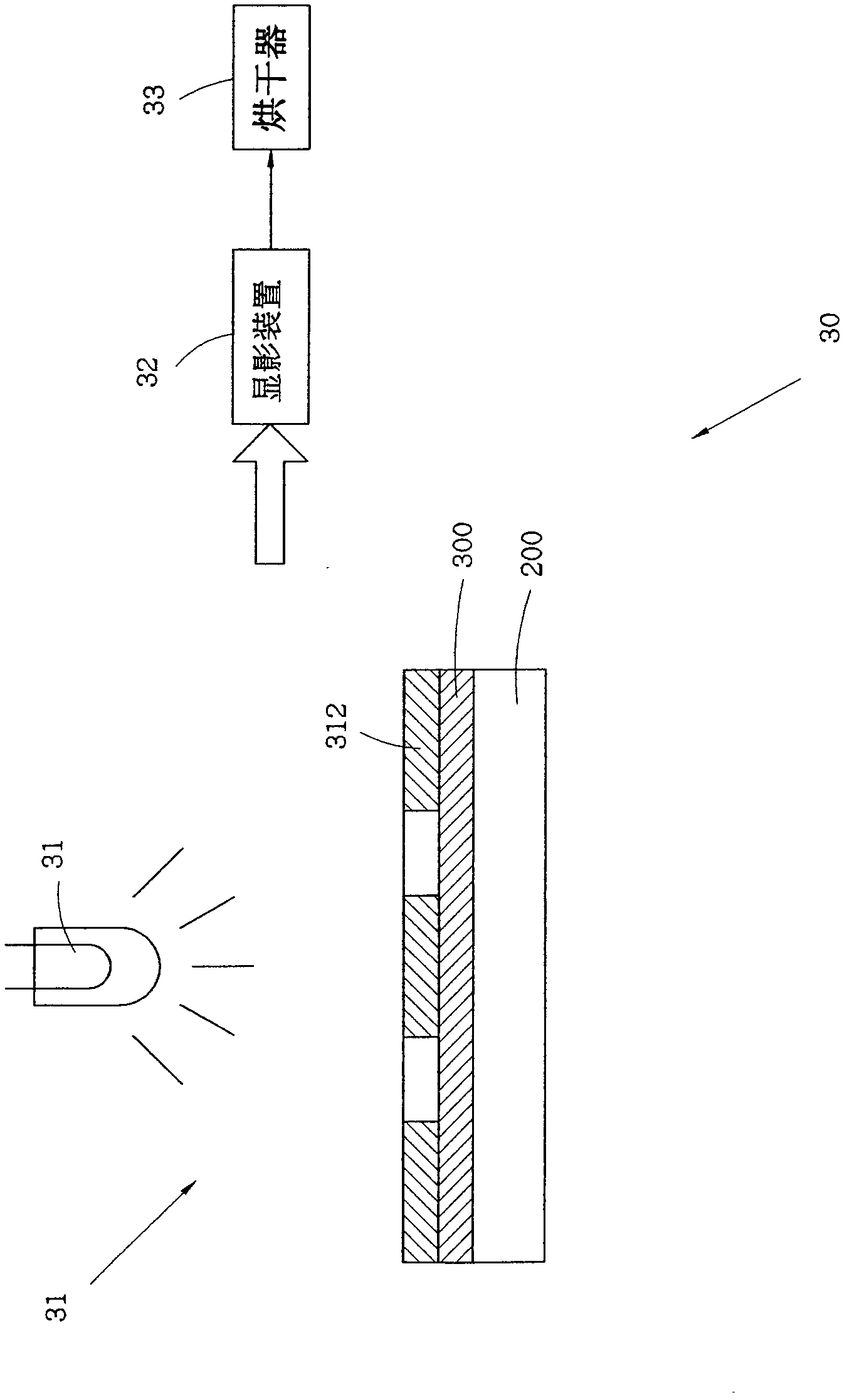

[0046] see figure 1 Shown, is the first embodiment of the processing device 100 of the glass sheet material of the present invention, wherein, the processing device 100 includes a feeding mechanism 10 to automatically feed a glass sheet material 200 to be processed, and the feeding mechanism 10 can be Consists of a circular conveyor belt, a film sticking mechanism 20, and automatically sticks an adhesive film 300 on at least one side of the above-mentioned glass plate 200 fed and processed by the feeding mechanism 10. The type of the adhesive film 300 is not limited, and in the first aspect of the present invention In the embodiment, the polymer film with photoresist properties is taken as an example, which has the function of producing water-insoluble strain after being irradiated with ultraviolet rays.

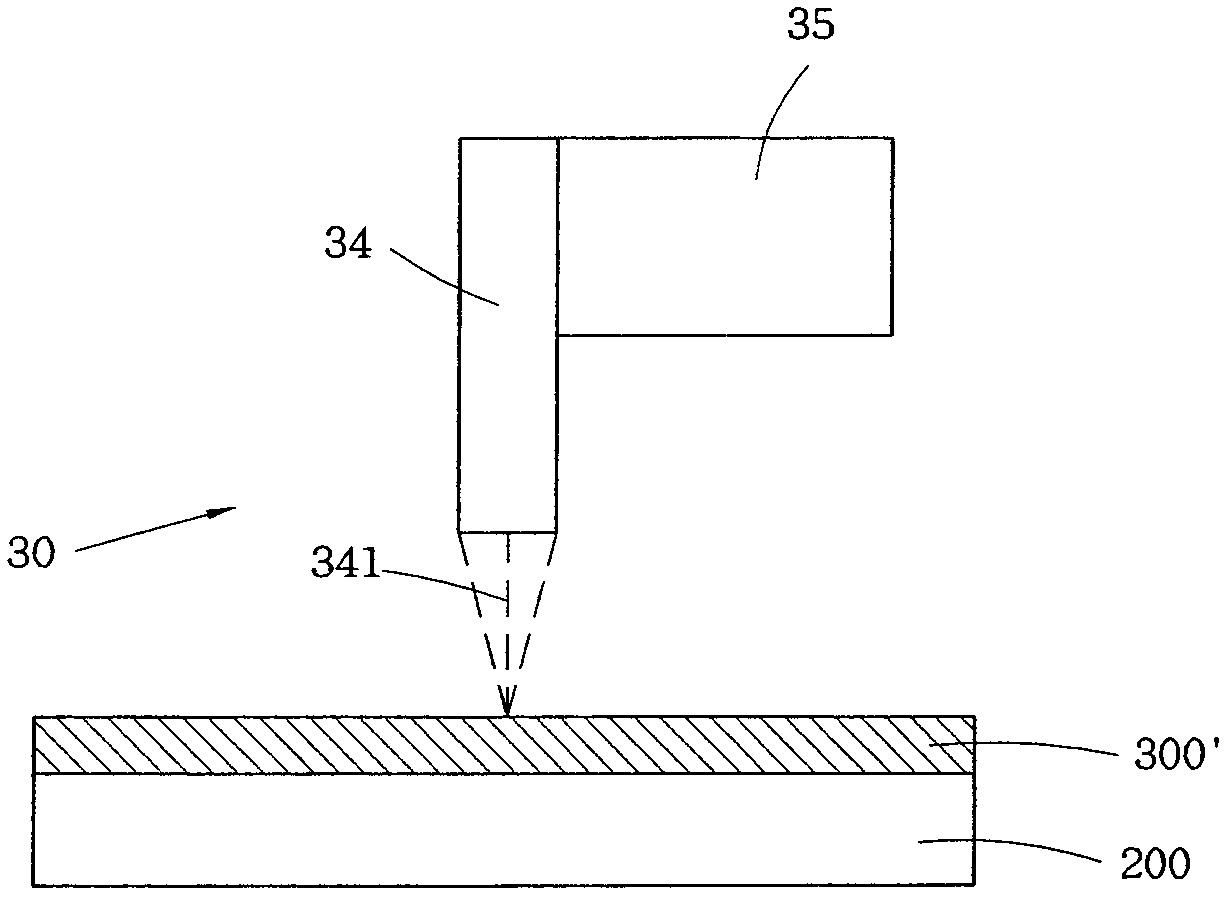

[0047] A processing path planning mechanism 30 is used to remove the portion of the glass plate 200 that does not need to be protected by the adhesive film 300 pasted by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com