Low-voltage electromagnet riveting method of metal-composite material combined structure

A technology of composite materials and composite structures, which is applied in the field of aviation and aerospace engineering manufacturing, can solve the problem that the riveting stability of metal and composite materials is not ideal, cannot meet the requirements for the stability of riveting quality of metal and composite material structures, and it is difficult to complete high-strength metal joints. - Composite material riveting and other problems, to achieve the effect of uniform radial deformation and uniform deformation of rivets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Embodiment 1: The low-voltage electromagnetic riveting method of metal composite composite structure, which is completed by the following steps:

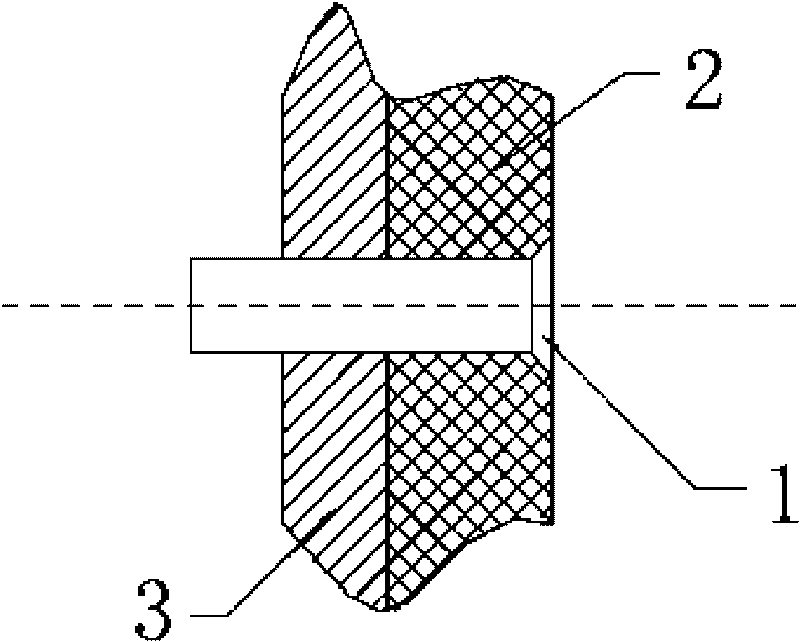

[0022] Step 1, fixing the combined structure of the metal 3 that has been drilled with the through hole and the composite material 2 that has been drilled with the through hole, and keeping the through hole on the metal 3 and the through hole on the composite material 2 on a horizontal line;

[0023] Step 2, passing the rivet 1 through the through hole on the metal 3 and the through hole on the composite material 2 described in step 1;

[0024] Step 3. Adjust the position of riveter 4 so that the rivet head of rivet gun 4 is in contact with the upsetting head side of rivet 1 in step 2, and the nail head side of rivet 1 is in contact with top iron 5, so that riveter 4, rivet 1 and top iron 5 are located on the same horizontal straight line;

[0025] Step 4: The low-voltage electromagnetic riveting system 6 is connected to the...

specific Embodiment approach 2

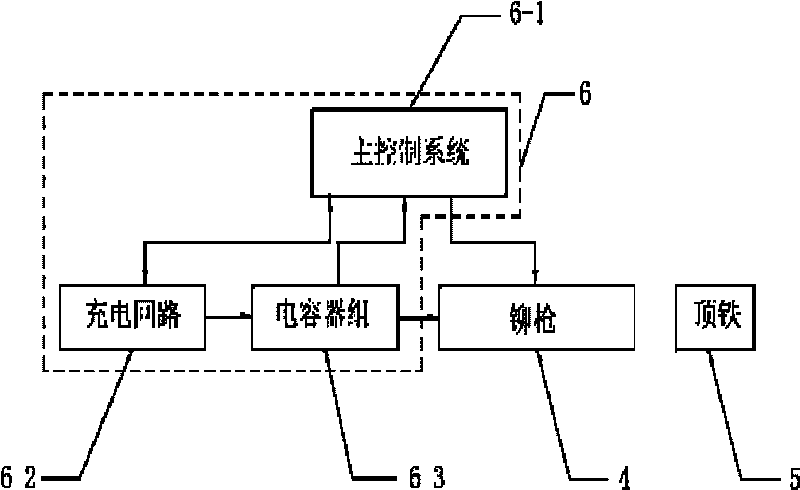

[0031] Specific implementation mode two: combination figure 1 Describe this specific embodiment. The difference between this specific embodiment and the low-voltage electromagnetic riveting method of the metal composite material composite structure described in specific embodiment 1 is that the low-voltage electromagnetic riveting system 6 also includes a main control system 6-1, a charging circuit 6- 2 and the capacitor bank 6-3, the current signal output end of the charging circuit 6-2 is connected to the current signal input end of the capacitor bank 6-3, and the current signal output end of the capacitor bank 6-3 is connected to the coil winding of the riveting gun 4, The control signal input / output end of the main control system 6-1 is connected to the output / input end of the charging circuit 6-2, the current signal output end of the capacitor bank 6-3 is connected to the current signal input end of the main control system 6-1, The control signal output end of the main co...

specific Embodiment approach 3

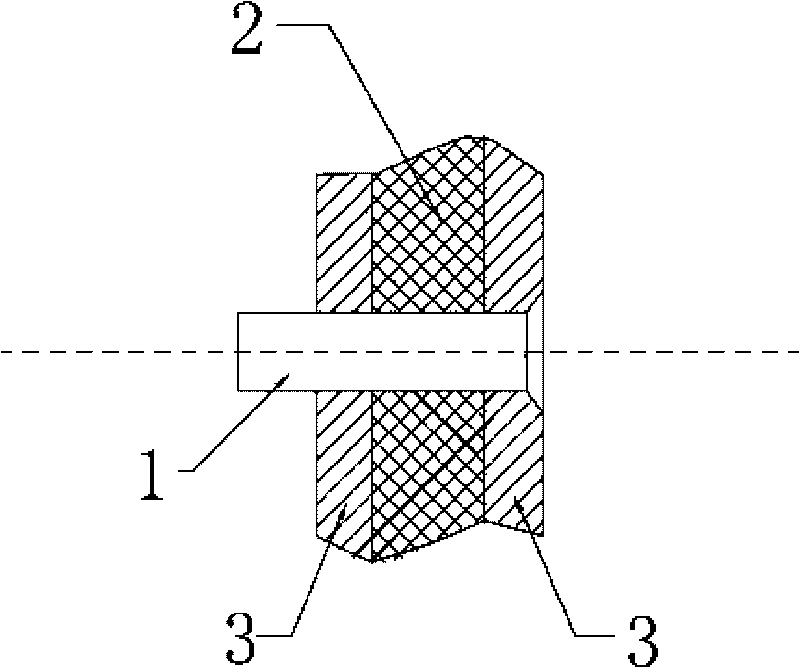

[0033] Specific implementation mode three: combination figure 2 , image 3 with Figure 4 Describe this specific embodiment. The difference between this specific embodiment and the low-voltage electromagnetic riveting method of the metal-composite material composite structure described in specific embodiment 1 or 2 is that the composite structure of the metal 3 and the composite material 2 is two or more layers .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com