Preparing technology for bionic molybdenum silicide gradient laminate compositing nanometer coatings

A technology of nano-coating and preparation process, which is applied in the direction of metal material coating process, coating, ion implantation plating, etc., can solve problems such as hindering the practical process, and achieve the purpose of inhibiting the expansion of instability, releasing the stress concentration at the tip, increasing the The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation process of biomimetic molybdenum silicide gradient laminated composite nano-coating, using dual-cathode plasma sputtering deposition method to form a dense nano-crystalline silicide layer on the surface of the pure titanium workpiece.

[0020] a. Double cathode plasma sputtering process parameters:

[0021] Target voltage900 V Workpiece voltage350 V Distance between target and workpiece 15 mm Ar pressure 35Pa Deposition temperature 700℃

[0022] b. Sputtering target type: component ratio is Mo 0.35 (Si 0.95 ,Al 0.05 ) 0. 65 Powder metallurgy sintered plate is the target material;

[0023] c. The type of workpiece material: pure titanium.

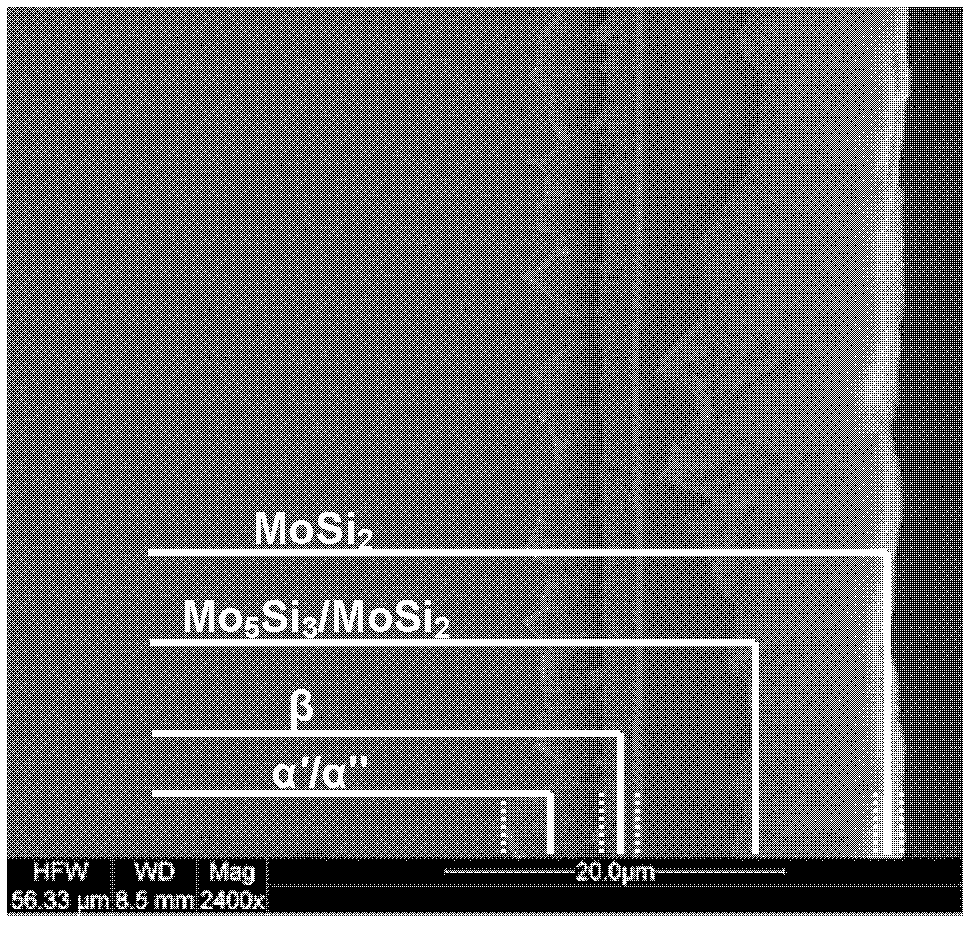

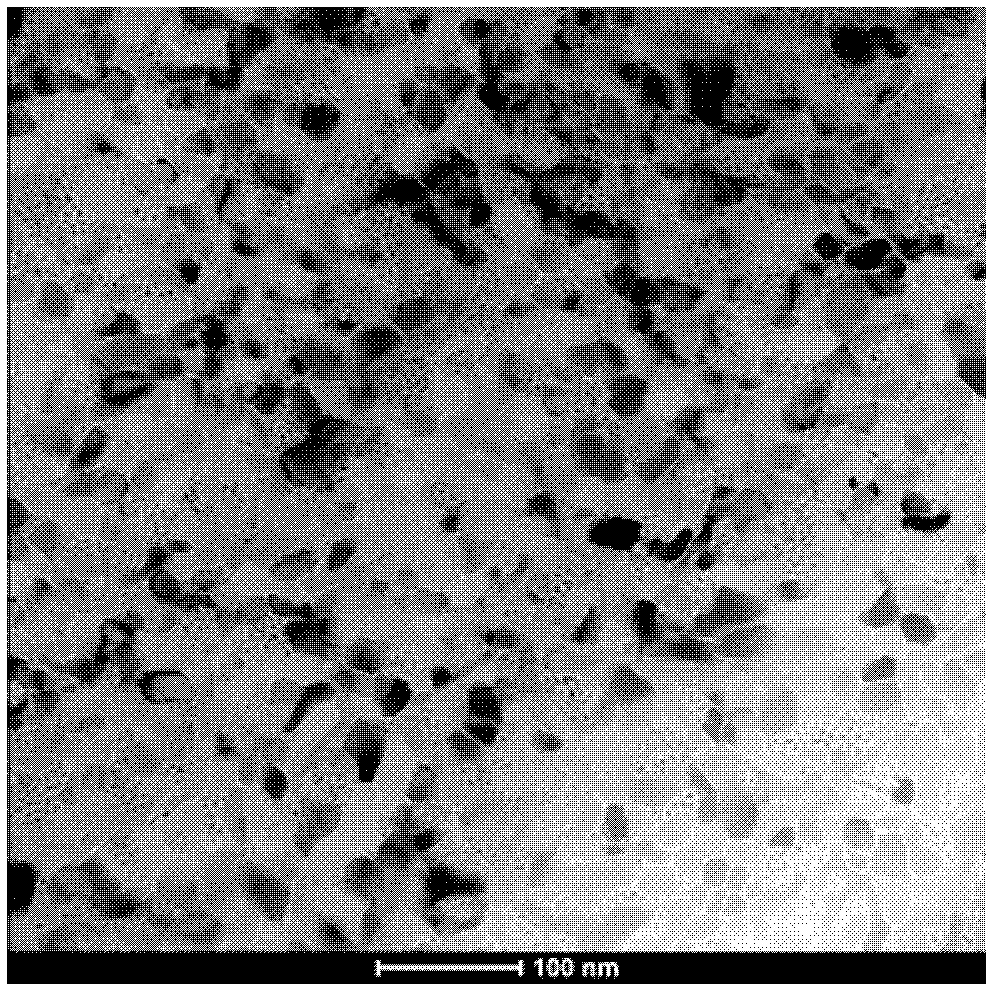

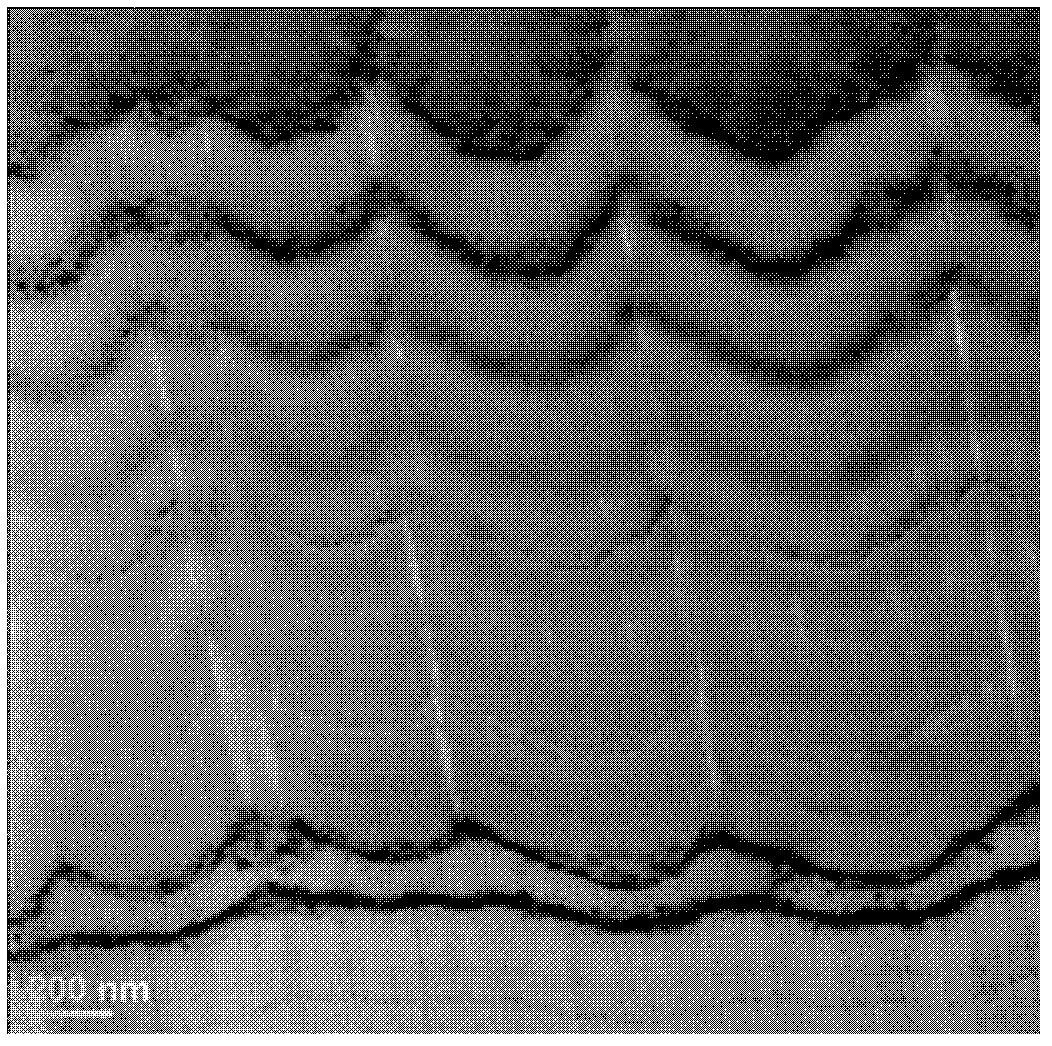

[0024] figure 1 The composition ratio prepared by the hot isostatic pressing process is Mo 0.35 (Si 0.95 ,Al 0.05 ) 0.65 The powder metallurgy sintered plate is the target material, and the SEM picture of the gradient composite nanocrystalline silicide coating formed on the pure Ti surface. figure 2 TEM picture of ...

Embodiment 2

[0028] The preparation process of biomimetic molybdenum silicide gradient laminated composite nano-coating, using double-cathode plasma sputtering deposition method to form a dense nano-crystalline silicide layer on the surface of pure titanium workpiece, among which a. Double-cathode plasma sputtering process parameters: target voltage 1000 V, workpiece voltage 450 V, target and workpiece distance 30 mm, Ar pressure 45 Pa, deposition temperature 800 ℃; b. Sputtering target species: Mo 0.35-55 (Si 0.95 ,Al 0.05 ) 0.65-45 Powder metallurgy sintered plate is the target material; c. The type of workpiece material: pure titanium. The coating performance obtained is slightly lower than that of Example 1.

[0029]

Embodiment 3

[0031] The preparation process of biomimetic molybdenum silicide gradient laminated composite nano-coating, using double-cathode plasma sputtering deposition method to form a dense nano-crystalline silicide layer on the surface of pure titanium workpiece, including a. Double-cathode plasma sputtering process parameters: target voltage 800V, workpiece voltage 300 V, target and workpiece distance 10 mm, Ar gas pressure 30 Pa, deposition temperature 600 ℃; b. Sputtering target type: the composition ratio is Mo 0.35-55 (Si 0.95 ,Al 0.05 ) 0.65-45 Powder metallurgy sintered plate is the target material; c. The type of workpiece material: pure titanium. The coating performance obtained is slightly lower than that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com