Application of waste contact as lithium ion battery negative material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, battery recycling, circuits, etc., can solve problems such as increasing production costs, unfavorable industrialization of lithium-ion silicon-based negative electrode materials, and damaging product coating structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Wash 5g of the waste contacts produced in the process of preparing organosilicon monomer methylchlorosilane by the fluidized bed process commonly used in the organosilicon industry with 100mL of benzene and ethanol twice, filter and store in a vacuum drying oven at 100°C Vacuum-dried for 2 hours to obtain a silicon / carbon / copper porous composite used as a negative electrode material for a lithium-ion battery.

[0078] The surface morphology of the silicon / carbon / copper porous composite prepared above was observed with a JSM6700 field emission scanning electron microscope produced by Japan Electronics Corporation.

[0079] The silicon / carbon / copper porous composite prepared above was subjected to XRD test on an X'Pert PRO MPD multifunctional X-ray diffractometer produced by Panalytical Company (Panalytical) in the Netherlands.

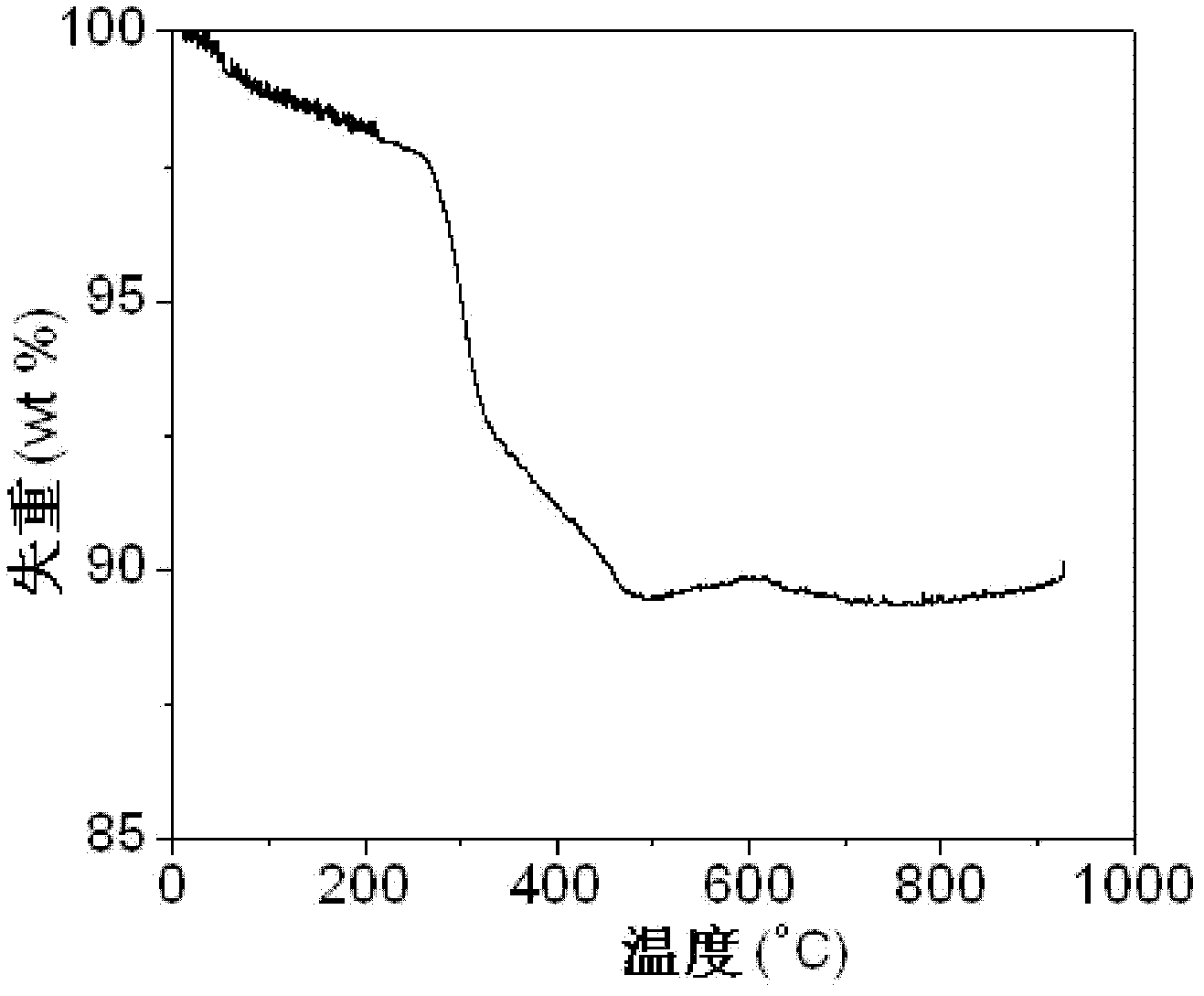

[0080] The silicon / carbon / copper porous composite prepared above was analyzed for thermogravimetric changes on a Nippon Seiko TG / DTA6300 thermog...

Embodiment 2

[0087] After washing 5 g of the waste contact body produced in the process of preparing organosilicon monomer methylchlorosilane by the fluidized bed process commonly used in the organosilicon industry with 100mL nitric acid twice, almost all the metal components in the complex were dissolved and removed. Wash with distilled water for 5 times, and then vacuum dry at 150° C. for 2 hours in a vacuum drying oven to obtain a silicon / carbon porous composite negative electrode material for lithium ion batteries. The electrochemical performance test of the silicon / carbon porous composite negative electrode material is the same as that of Example 1, the initial reversible capacity is 1861mAh / g, and the reversible capacity retention rate is above 50% after 20 cycles.

[0088] Figure 4 The middle spectrum (b) is the XRD spectrum of the silicon / carbon porous composite obtained in Example 2. Compared with the pure silicon spectrum (c) of the raw material, it can be seen that the composit...

Embodiment 3

[0092] Put 5 g of the waste contacts produced during the preparation of organosilicon monomer methylchlorosilane by the fixed bed process commonly used in the organosilicon industry, and place them in a high-temperature furnace for calcination in air at a temperature of 600°C for 2 hours. After calcination Cool naturally to room temperature to obtain a silicon / copper oxide porous composite negative electrode material for lithium ion batteries. The electrochemical performance test of the silicon / copper oxide porous composite negative electrode material is the same as that of Example 1, the initial reversible capacity is 1867mAh / g, and the reversible capacity retention rate is above 20% after 20 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com