Lead-free piezoelectric film material and preparation method thereof

A thin-film material, lead-free piezoelectric technology, applied in the field of functional ceramic materials, can solve the problems of high sol viscosity, film micro-cracks, poor insulation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

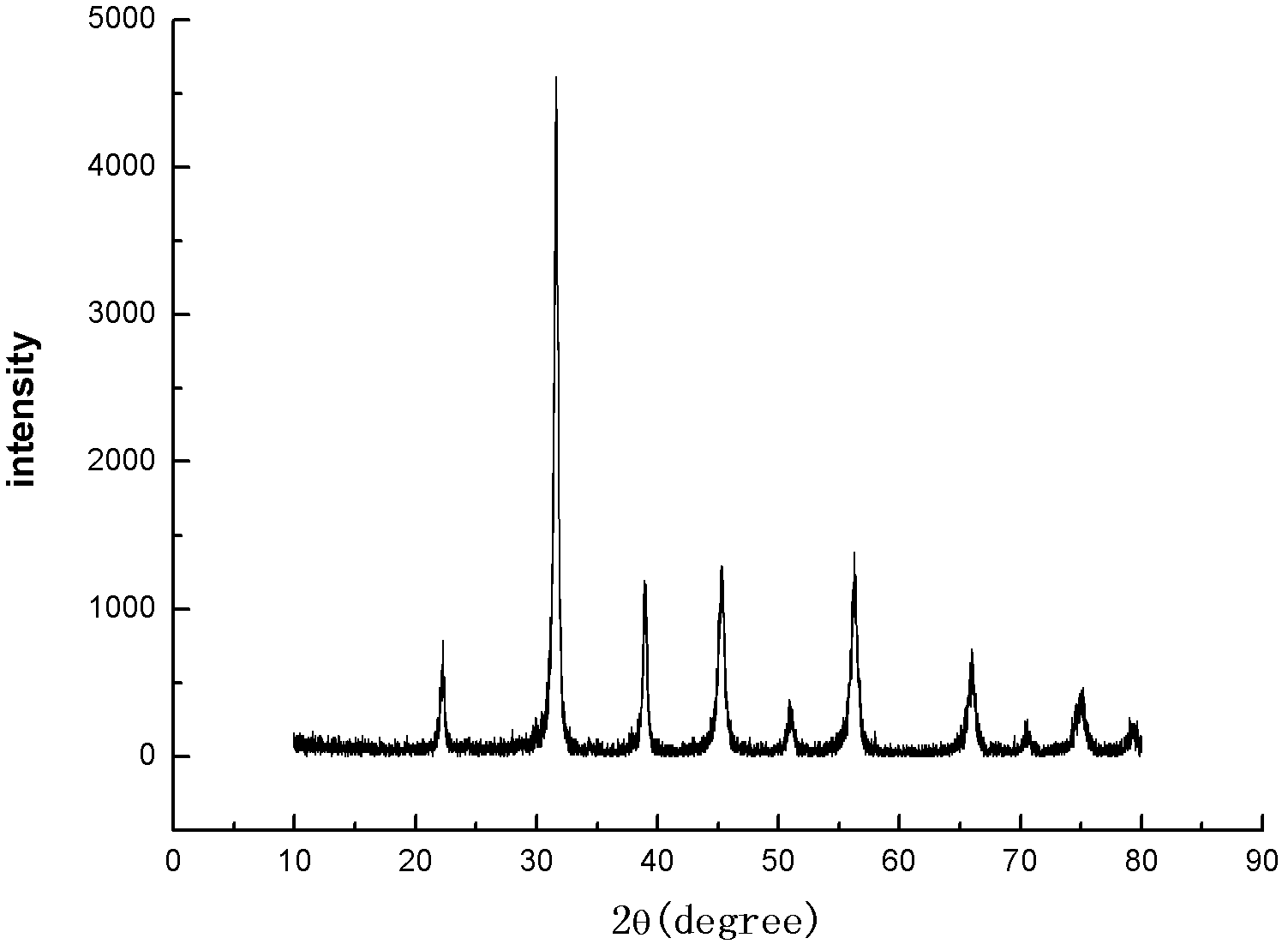

Image

Examples

Embodiment Construction

[0027] Non-limiting examples are described as follows:

[0028] The raw materials required for the experiment are barium acetate (analytical pure, content 99%), calcium acetate (analytical pure, content 98%), strontium acetate (analytical pure, content 99%), tetrabutyl titanate (chemically pure, content 98%) %), niobium citrate (analytical pure, content 99%), ferric citrate (analytical pure, content 99%). Reagents Glacial acetic acid (analytical pure, content 99%), ethylene glycol dimethyl ether (analytical pure, content 99%), formamide (analytical pure, content 99%).

[0029] 1. To prepare 0.1mol / l, 40ml of (Ba 0.9 Ca x Sr 0.1-x )(Ti 0.87 Nb y Fe 0.13-y )O 3 Sol is taken as an example, and each raw material is weighed separately according to the mol ratio for later use.

[0030] Weigh barium acetate, calcium acetate and strontium acetate according to the weight calculated above and dissolve them in 20 ml of glacial acetic acid, stir the mixed solution on a magnetic st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com