Sound-insulation composite material based on polyester-waste tire rubber and preparation method for sound-insulation composite material

A technology for waste tire rubber and composite materials, which is applied in the field of sound insulation composite materials and its preparation, can solve the problems of cost and comprehensive mechanical properties of materials, large amount of tungsten powder added, unsuitable for long-term and high temperature use, etc. The effect of improving living standards, excellent sound insulation performance, and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

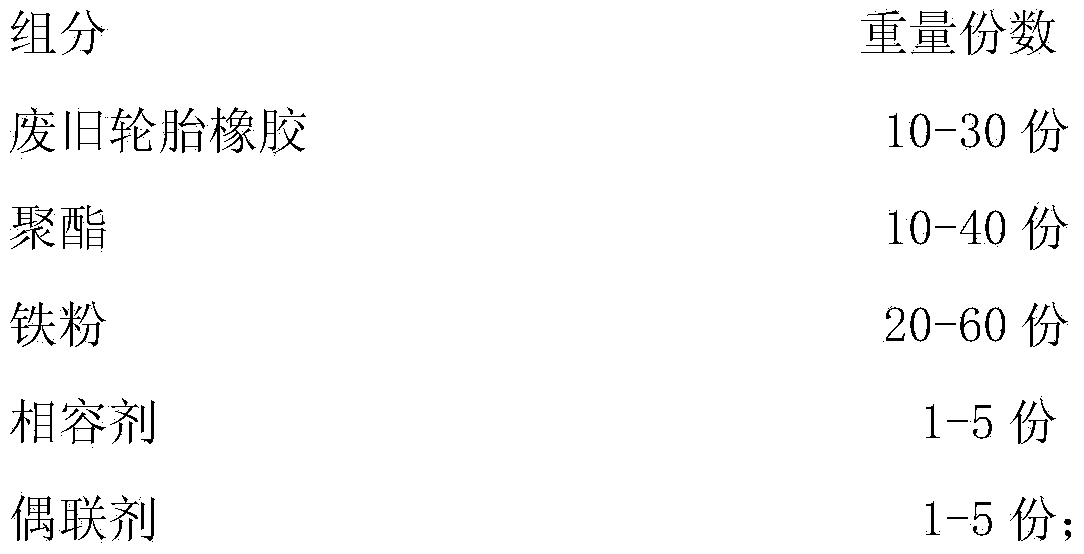

Method used

Image

Examples

Embodiment 1

[0026] (1) 10 parts of waste tire rubber powder, 24 parts of polyethylene terephthalate, 60 parts of reduced iron powder with a particle size of 200 mesh, and 4 parts of maleic anhydride graft hydrogenated styrene-ethylene-butadiene-benzene The ethylene block copolymer and 2 parts of monoalkoxy titanate coupling agent (Kenrich Petrochemical Company, USA, KR-TTS) were put into the internal mixer together for internal mixing. Process parameters: temperature is 285°C; time is 10min; screw speed is 50r / min. ;

[0027] (2) Thermocompression forming to make a film of 1 mm. The process parameters are: hot-pressing temperature: 285°C; pressure: 10MPa; holding time: 10min; film thickness: 1mm.

[0028] Its average sound insulation is around 31 decibels.

Embodiment 2

[0030] (1) 23 parts of waste tire rubber powder, 10 parts of polytrimethylene terephthalate, 60 parts of reduced iron powder with a particle size of 200 mesh, 3 parts of maleic anhydride grafted hydrogenated styrene-ethylene-butadiene-styrene The segment copolymer and 4 parts of monoalkoxy phosphate titanate coupling agent (Kenrich Petrochemical Company, USA, KR-12) were put into the internal mixer together for internal mixing. Process parameters: temperature is 235°C; time is 10min; screw speed is 50r / min. ;

[0031] (2) Thermocompression forming to make a film of 1 mm. The process parameters are: hot pressing temperature: 235° C.; pressure: 10 MPa; holding time: 10 min; film thickness: 1 mm.

[0032] Its average sound insulation is around 33 decibels.

Embodiment 3

[0034] (1) 30 parts of waste tire rubber, 40 parts of polybutylene terephthalate, 20 parts of iron powder with a particle size of 400 mesh, and 5 parts of maleic anhydride grafted hydrogenated styrene-ethylene-butadiene-styrene The block copolymer and 5 parts of monoalkoxy unsaturated fatty acid titanate (Kenrich Petrochemical Company of the United States, KR-95) were added together in an internal mixer for internal mixing. Process parameters: temperature is 245°C; time is 5min; screw speed is 10r / min. ;

[0035] (2) Thermocompression forming to make a film of 1 mm. The process parameters are: hot pressing temperature: 245; ℃; pressure: 10MPa; holding time: 5min; film thickness: 1mm.

[0036] Its average sound insulation is around 25 decibels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com