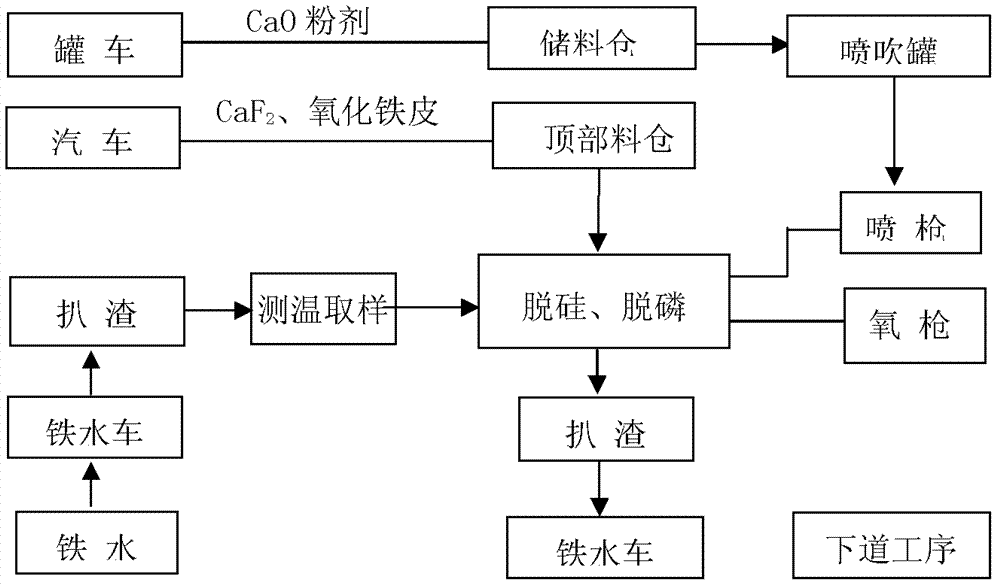

Low-temperature molten iron injection dephosphorization pretreatment method

A low-temperature molten iron and pretreatment technology, applied in the direction of improving process efficiency, can solve the problems of large investment in disposable equipment, small production capacity, and large floor area, so as to reduce the dephosphorization treatment cycle, reduce the temperature drop of molten iron, The effect of reducing the temperature drop of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

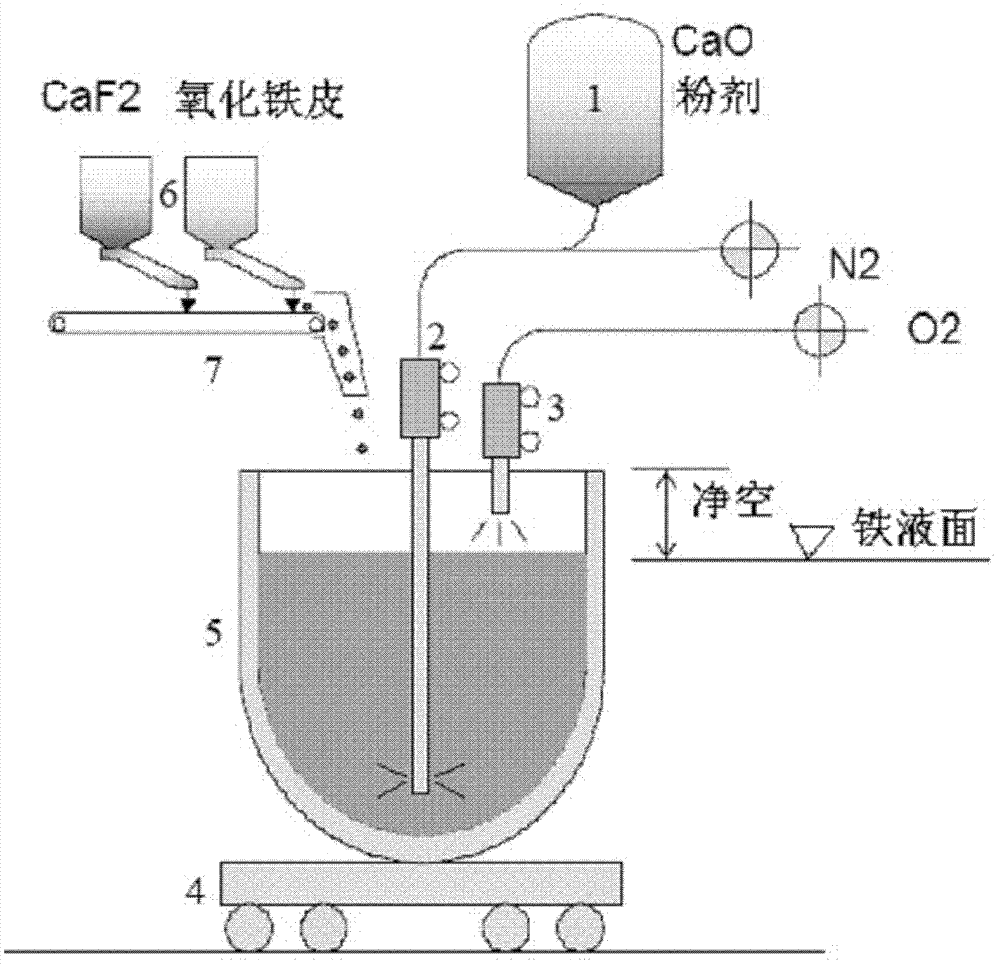

[0019] (1) Use the dephosphorization special molten iron tank 5 to hold molten iron (the weight of the molten iron is weighed in real time), transport the weighed dephosphorization special molten iron tank to the tipping car 4, click the tipping car on the control screen to the slag removal position (scraping The slag position is at the same position as the desiliconization and phosphorus treatment position) button, the dumper runs to the slag removal position, and then the slag removal operator operates the dumper (the operation button and the slag removal machine are operated on the same console) The molten iron tank (the tipping angle of the special tank for dephosphorization changes in real time between 0° and 52°, the specific tipping angle is subject to the fact that the molten iron does not flow out of the molten iron tank mouth) and the slag removal machine perform the slag removal operation.

[0020] (2) After the slag removal is completed, the molten iron tipping tran...

Embodiment 2

[0025] (1) The steps are the same as in Example 1.

[0026] (2) After the slag removal is completed, the molten iron tipping transport vehicle 4 runs to the temperature measurement sampling position to measure the temperature of the molten iron and sample the molten iron temperature (1171 ° C), molten iron weight (32t), composition (C: 4.14%; Si: 0.32%; Mn: 0.32%; P: 0.075; S: 0.026 content) and target phosphorus requirements (≤0.005%) are input into the control interface, and the program automatically sets the injection volume of desiliconization and phosphorus agent (795kg), And the amount of iron oxide scale (348kg), fluorite (100kg) and the amount of oxygen blown (753Nm 3 ), the desiliconization and dephosphorization treatment starts automatically. During the treatment process, the desiliconization and phosphorus agent (CaO powder) is sprayed into the molten iron through the spray gun 2 in the form of dense phase transport under the action of the carrier gas from the powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com