Hindered amine light stabilizer with toughening effect and preparation method thereof

A technology of hindered amine light stabilizer and light stabilizer, which is applied in the field of light stabilizer and its preparation, can solve the problems of reducing intermolecular force, destroying the condensed state structure of materials, and reducing the mechanical properties of materials, so as to reduce physical loss, The best effect of improving thermal stability, compatibility and dispersion degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

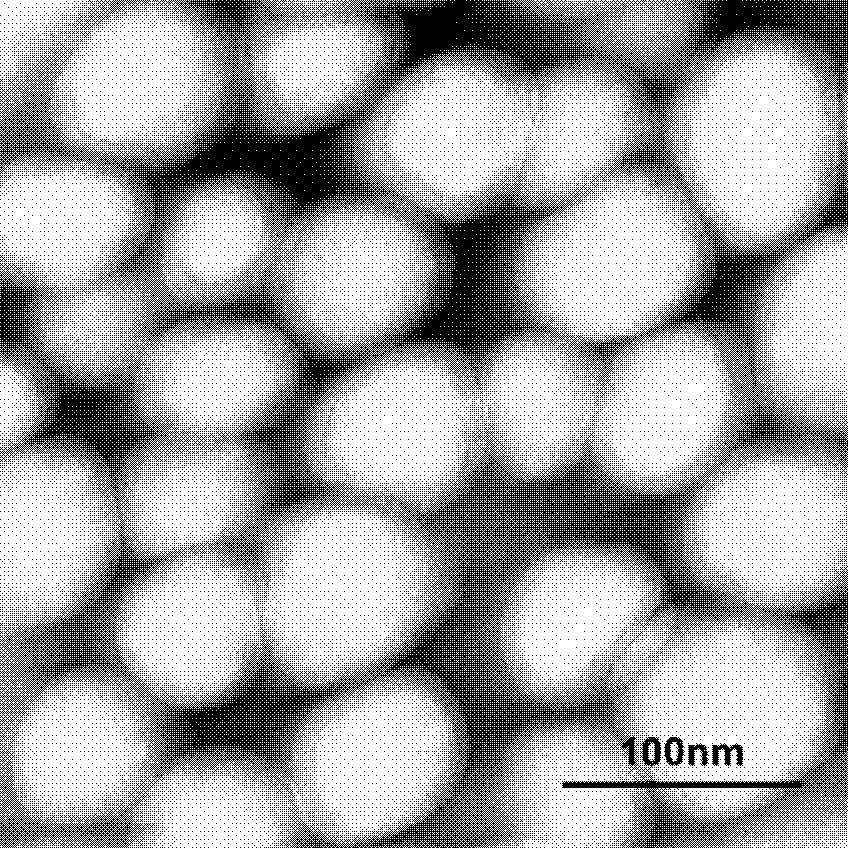

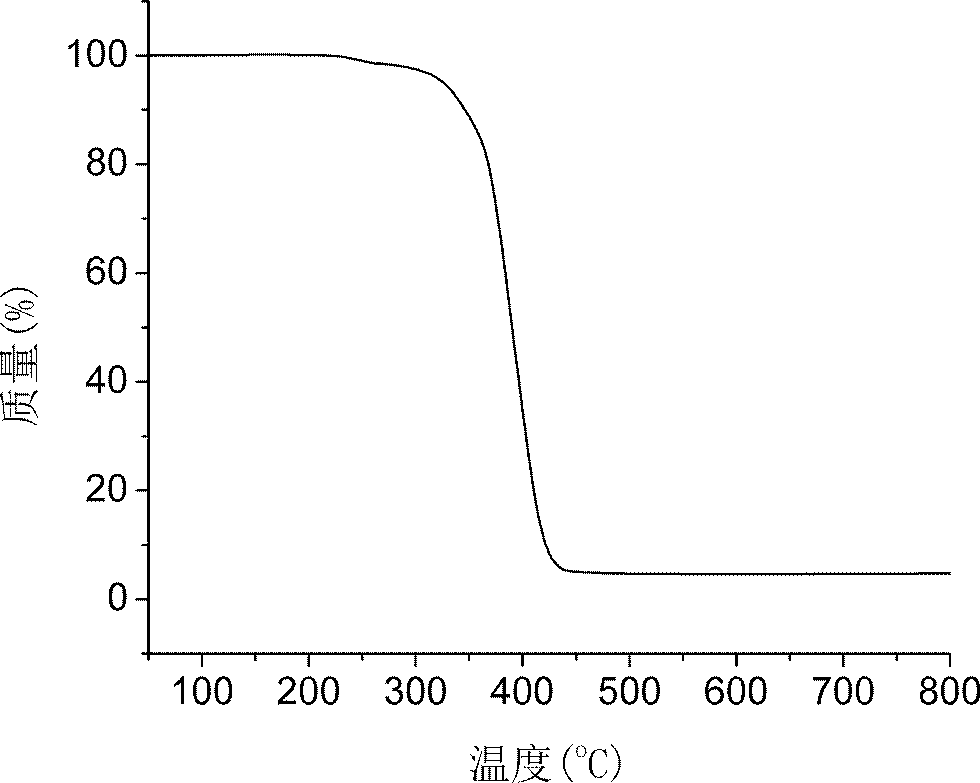

[0028] First add 100 parts of ethyl acrylate, 1 part of divinylbenzene, 4 parts of sodium dodecyl sulfonate, 2 parts of sodium carbonate and 200 parts of water to the reaction kettle, stir at 600 rpm for 0.5 hours, then Add 0.8 part of ammonium persulfate, and continue to stir at 600 rpm, heat up to 75 ℃ for 0.5 hours, then react at a stirring speed of 100 rpm for 3 hours to obtain a core emulsion; add 0.5 part to the core emulsion Ammonium persulfate, then add 40 parts methyl methacrylate and 60 parts 4-acryloyloxy-1,2,2,6,6-pentamethylpiperidine dropwise at a temperature of 75°C and a stirring speed of 100 rpm The mixture of pyridine is added dropwise within 3 hours, and the reaction is continued for 1 hour to obtain the polymer emulsion of the core-shell structure hindered amine light stabilizer; the above polymer emulsion is cooled to room temperature, and then the mass concentration is twice the volume of the polymer emulsion 5% CaCl 2 Aqueous solution demulsification, pre...

Embodiment 2

[0031] First add 100 parts of hexyl acrylate, 3 parts of diallyl terephthalate, 3 parts of sodium lauryl sulfate, 1 part of sodium bicarbonate and 300 parts of water into the reaction kettle, and stir at 400 rpm 0.7 hours, then add 1.0 part of potassium persulfate, and continue to stir at 400 rpm, heat up to 80 ℃ for 1 hour, then react at a stirring speed of 50 rpm for 4 hours to obtain a nuclear emulsion; Add 1.0 part of potassium persulfate into it, then add 80 parts of styrene and 40 parts of 4-methacryloyloxy-1,2,2,6,6-penta at a temperature of 80°C and a stirring speed of 50 rpm. The mixture of methylpiperidine was added dropwise within 3.5 hours, and the reaction was continued for another 1.5 hours to obtain the polymer emulsion of the core-shell structure hindered amine light stabilizer; the polymer emulsion was cooled to room temperature, and then 2.5 times the volume of the polymer emulsion The mass concentration is 10% CaCl 2 Aqueous solution demulsification, precipit...

Embodiment 3

[0034] First add 100 parts of butyl acrylate, 3 parts of diallyl maleate, 6 parts of sodium dodecyl sulfonate, 2 parts of sodium bicarbonate and 300 parts of water into the reactor, and stir at 800 rpm 1 hour, then add 1.5 parts of azobisisobutyronitrile, and continue stirring at 800 rpm, heating to 78°C for 0.8 hours, and then reacting at a stirring speed of 150 rpm for 3.5 hours to obtain a nuclear emulsion; Add 1.0 part of azobisisobutyronitrile to the core emulsion, then add 80 parts of acrylonitrile and 80 parts of 4-acryloyloxy-2,2,6,6 at a temperature of 78°C and a stirring speed of 150 rpm. -The mixture of tetramethylpiperidine is added dropwise within 4 hours, and the reaction is continued for 2 hours to obtain the polymer emulsion of the core-shell structure hindered amine light stabilizer; the polymer emulsion is cooled to room temperature, and then the volume of the polymer emulsion 3 times the mass concentration of 8% CaCl 2 Aqueous solution is demulsified, precipi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com