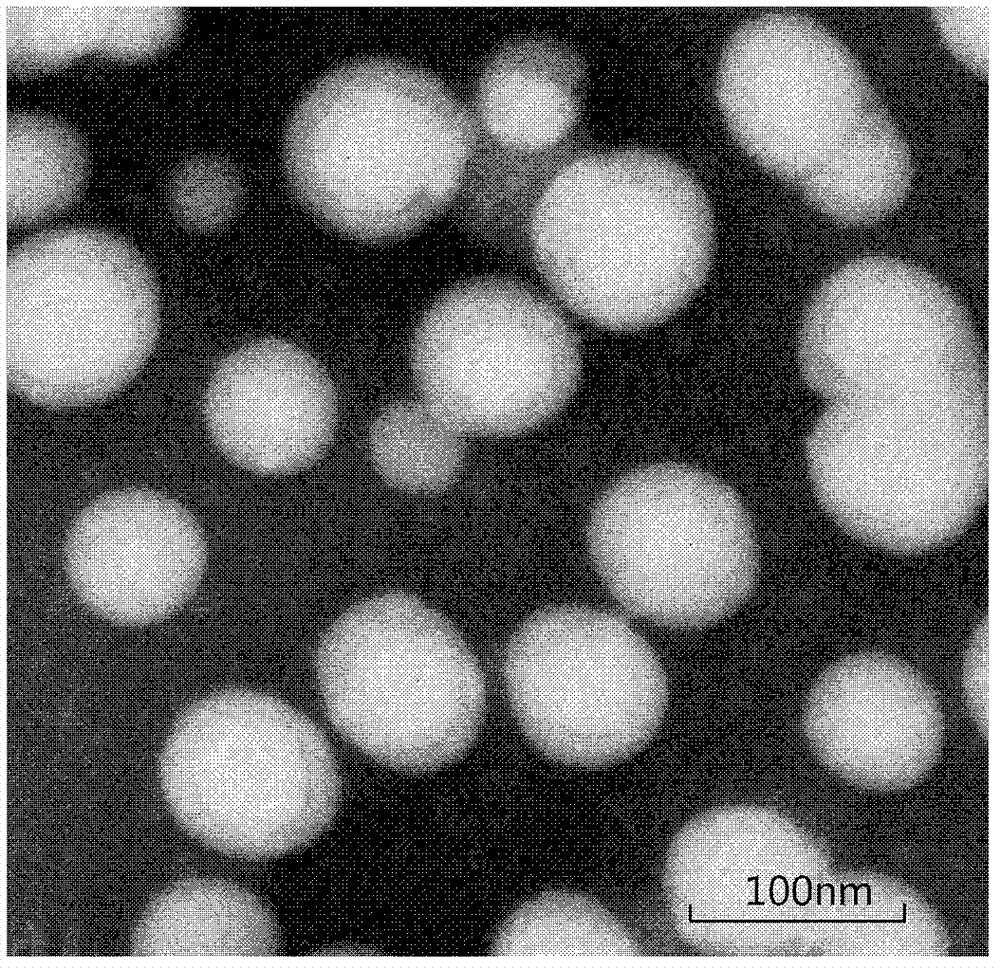

Polyacrylate elastomer with core-shell structure and its preparation method

A technology of polyacrylate and core-shell structure, which is applied in the field of core-shell structure polyacrylate elastomer and its preparation, can solve the problem of not being able to contribute to the toughness of polymer materials, limiting the application range of polymer materials, and not possessing the toughness of elastomers, etc. problem, achieve the effect of maintaining durability, improving mechanical properties and reducing migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

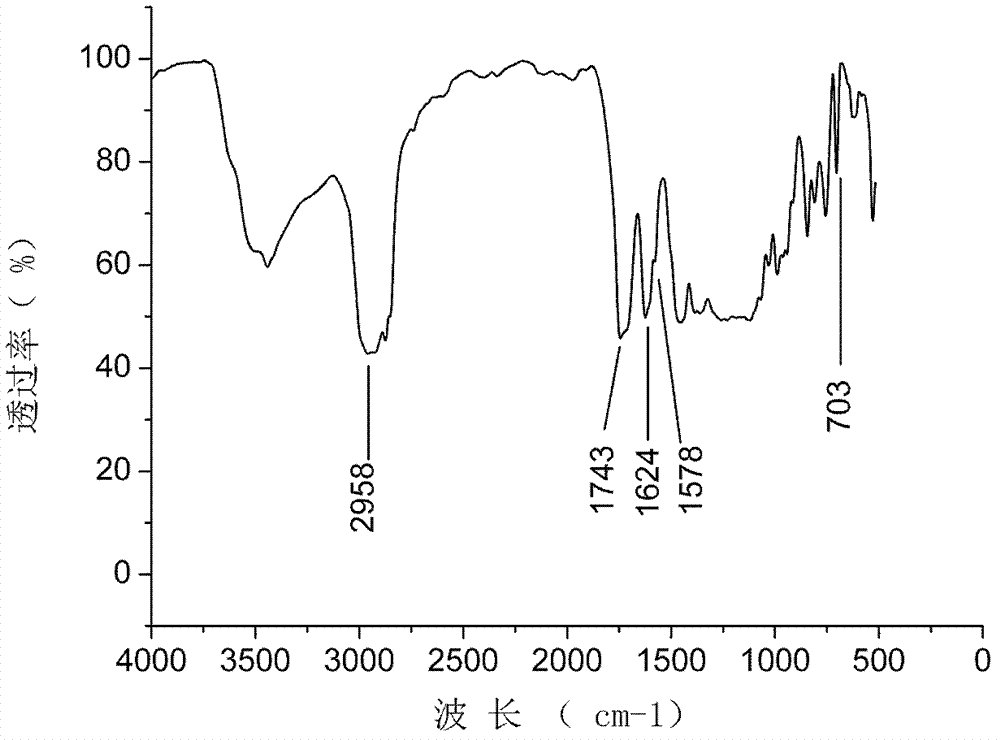

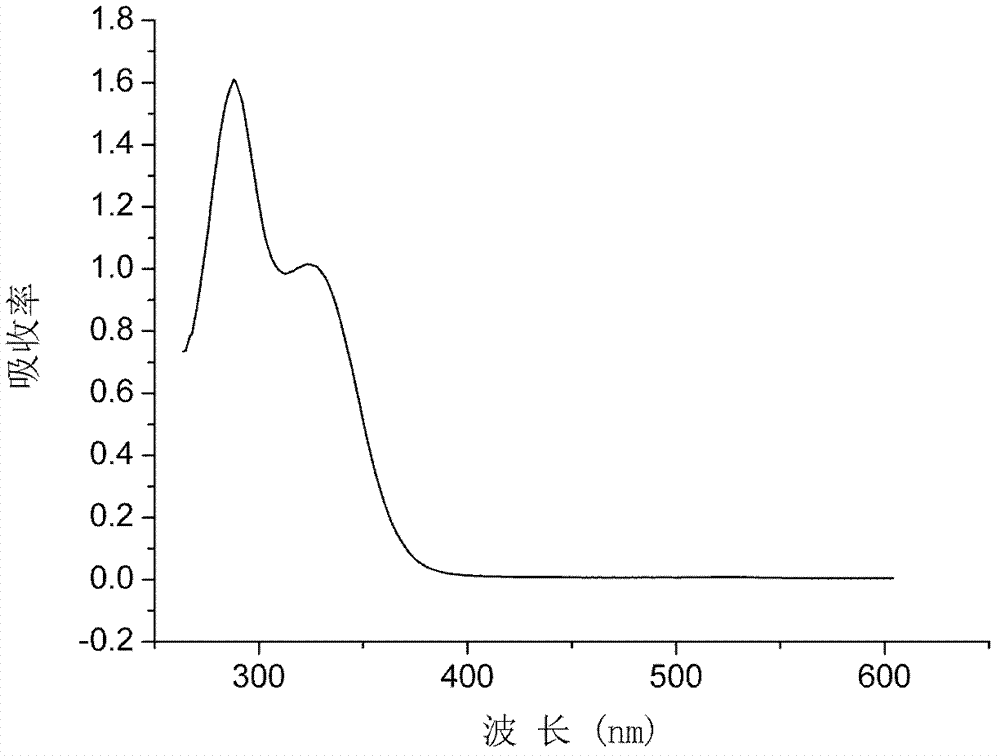

Embodiment 1

[0040] 40 parts of butyl acrylate, 10 parts of methyl methacrylate, 10 parts of 2-hydroxyl-4-(-3-methacrylate-2-hydroxypropoxyl) benzophenone, and the total mass of compound emulsifier 50% of the total mass of deionized water and 50% of the total mass of deionized water, fully stirred and mixed to obtain a pre-emulsion of the core layer monomer; 10 parts of methyl methacrylate, 10 parts of butyl acrylate, 2-hydroxyl-4-(-3 - 10 parts of methacrylate-2-hydroxypropoxy) benzophenone, 50% of the total mass of the composite emulsifier and 50% of the total mass of deionized water, fully stirred and mixed to prepare the shell monomer pre-emulsification 30% of the total mass of the obtained nuclear layer monomer pre-emulsion, 50% of the total mass of the pH regulator and 15% of the total mass of the initiator, stirred and mixed and heated up to 70 ° C, until the blue phase appeared in the emulsion, continue to stir and keep warm The core seed microemulsion was prepared in 30 minutes; t...

Embodiment 2

[0043] 40 parts of butyl acrylate, 30 parts of ethyl acrylate, 50% of the total mass of the composite emulsifier and 50% of the total mass of deionized water were fully stirred and mixed to obtain a pre-emulsion of the core layer monomer; the methacrylate EMA10 Parts, 20 parts of 2-hydroxyl-4-(-3-methacrylate group-2-hydroxypropoxy) benzophenone, 50% of the total mass of the composite emulsifier and 50% of the total mass of deionized water, Thoroughly stir and mix to obtain the shell layer monomer pre-emulsion; 50% of the total mass of the obtained core layer monomer pre-emulsion, 50% of the total mass of the pH regulator and 30% of the total mass of the initiator, stirring and mixing are heated up to 70 ℃, until the blue phase appears in the emulsion, continue to stir and insulate for 30 minutes to obtain the nuclear seed microemulsion; first the prepared nuclear seed microemulsion is warmed up to 75 ℃, and then respectively add 50% of the total mass of the nuclear layer monom...

Embodiment 3

[0046] 20 parts of ethyl acrylate, 25 parts of diethylhexyl acrylate, 5 parts of 2-hydroxy-4-(-3-methacrylate-2-hydroxypropoxy) benzophenone, and a total of compound emulsifiers 60% of the mass and 60% of the total mass of deionized water, fully stirred and mixed to obtain a pre-emulsion of the core layer monomer; 20 parts of ethyl methacrylate, 20 parts of isobutyl methacrylate, 2-hydroxyl-4 -10 parts of (-3-methacrylate-2-hydroxypropoxy) benzophenone, 40% of the total mass of the composite emulsifier and 40% of the total mass of deionized water, fully stirred and mixed to obtain a shell Monomer pre-emulsion: 30% of the total mass of the obtained nuclear layer monomer pre-emulsion, 60% of the total mass of the pH regulator and 20% of the total mass of the initiator, stirred and mixed and heated to 75 ° C, until the blue phase appeared in the emulsion , continue to stir and insulate for 40 minutes to make the nuclear seed microemulsion; first the nuclear seed microemulsion tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com