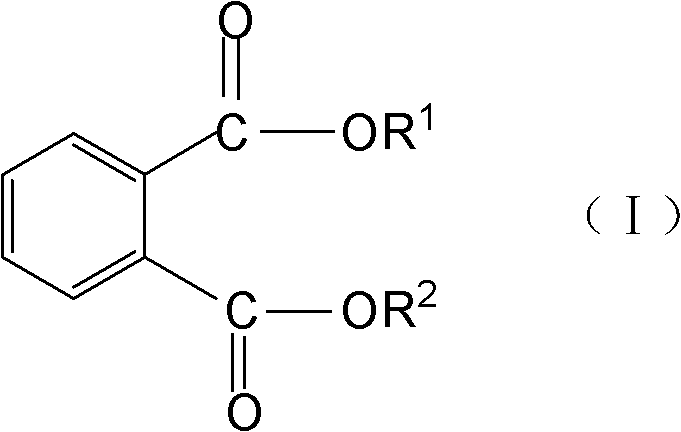

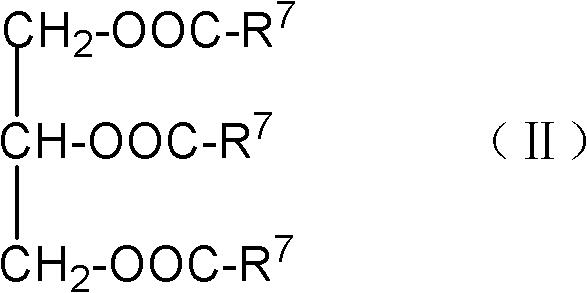

Composite floatation collector and preparation method thereof

A collector and flotation technology, applied in the field of collectors, can solve the problems of short duration of foaming, weak emulsification ability of hydrocarbon oil, limited dispersing ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] at 2m 3 Add 450 parts of diethyl phthalate, 450 parts of cyclohexanone by-product and 900 parts of diesel oil into the reaction kettle, stir at room temperature for 20 minutes, and the obtained light yellow oily liquid is a combined flotation collector.

Embodiment 2

[0033] at 2m 3 Add 400 parts of diethyl phthalate, 400 parts of sec-octanol and 1200 parts of waste engine oil into the reaction kettle, stir at 30°C for 20 minutes, and the obtained dark brown oily liquid is another combined flotation collector.

Embodiment 3

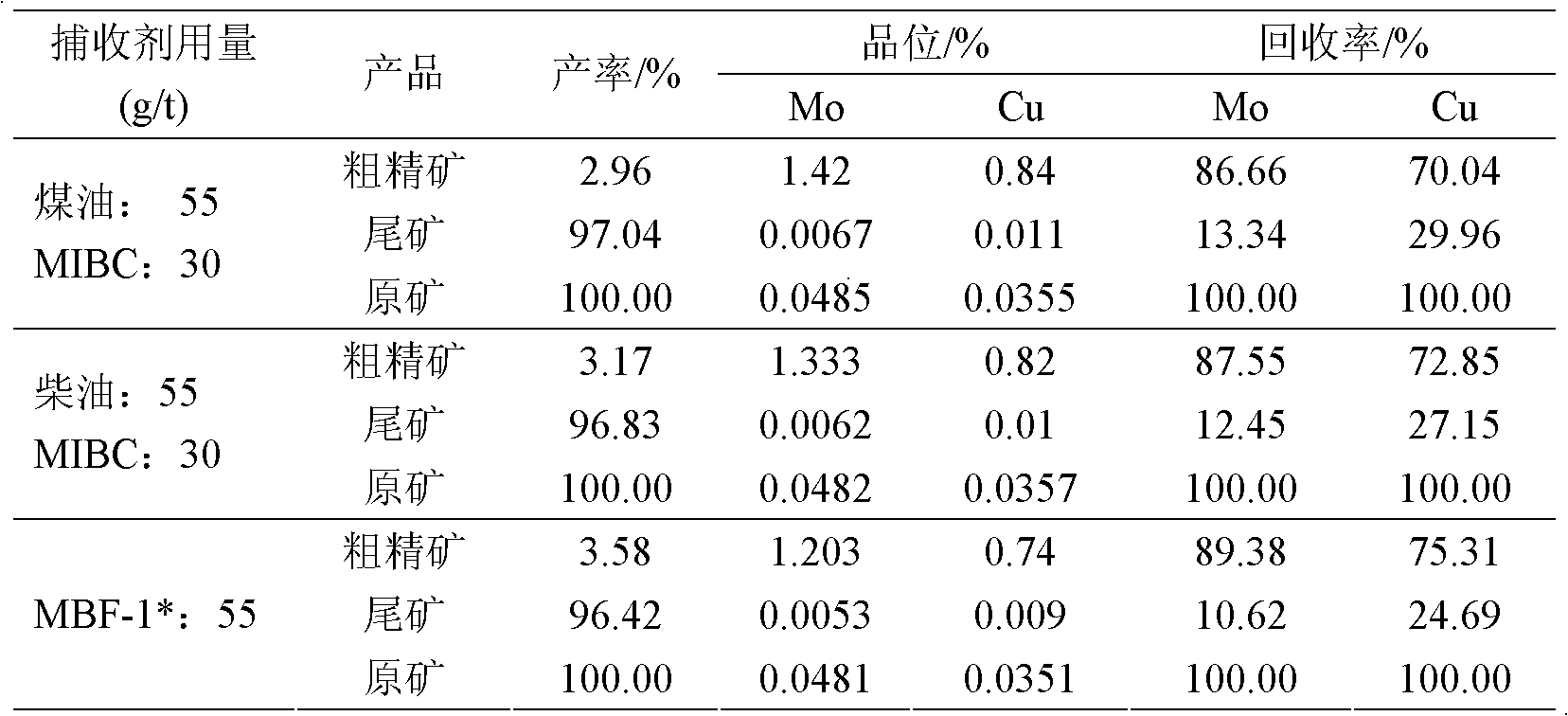

[0035] The ore sample is a large molybdenum ore, and the common metal sulfide minerals include molybdenite, chalcopyrite and pyrite. The gangue minerals are mainly quartz, plagioclase and potassium feldspar, followed by sericite, biotite, chlorite, kaolinite and calcite. The raw ore contains 0.048% molybdenum and 0.035% copper. The ore sample is crushed to -2mm and put into a ball mill. The ball mill used is XMBΦ200mm×400mm. Grinding 1Kg ore sample each time, the grinding concentration is 62.5%, and the grinding fineness is -200 mesh, accounting for 65%. The 3L XFD-63 type single tank flotation machine is used for flotation, each flotation ore sample is 1Kg, the concentration of the flotation pulp is 30%, and the collector and foaming agent are added to obtain the coarse concentrate (foam product) and Tailings (slurry in tank). The flotation test conditions and their results are shown in Table 1.

[0036] Table 1 Collector comparison test results

[0037]

[0038] * MB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com