Fireproofing original bamboo floorslab

A bamboo building and fireproof layer technology, applied in fireproofing, floor slabs, building components, etc., can solve the problems of complex construction, large consumption of steel bars and cement, and many gaps, so as to improve indoor sanitation conditions, high floor bearing capacity, and ecological protection environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

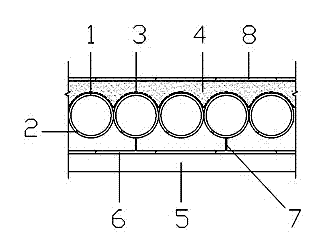

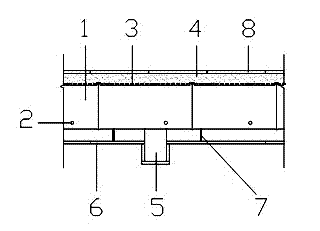

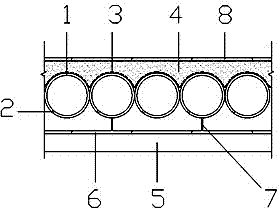

[0026] Embodiment 1: as figure 1 , 2 As shown, the original fireproof bamboo floor slab comprises wooden floor flutes 5, bamboo rafts 1, flexible waterproof layer 3, light clay layer 4, floor tile surface layer 8, fireproof layer 6 and hanging bars 7. Each closed cavity of the original bamboo has a small pressure relief hole 2, and a plurality of original bamboos are arranged closely on the wooden floor flute 5 to form a bamboo raft 1, and the upper surface of the bamboo raft 1 is laid with a wave-shaped flexible waterproof layer consistent with its shape 3. The flexible waterproof layer 3 is laid with a light clay layer 4 whose upper surface is flat, and the floor tile surface layer 8 is laid on the upper surface of the light clay layer 4; the gypsum board fireproof layer 6 is hung under the original bamboo layer 1 through hanging ribs 7 .

[0027] The production process of this fireproof original bamboo floor slab is: first drill a pressure relief hole 2 on each internode...

Embodiment 2

[0028] Embodiment 2: as figure 1 , 2 As shown, the original fireproof bamboo floor slab includes steel floor flute 5, bamboo raft 1, flexible waterproof layer 3, light clay layer 4, wooden floor surface layer 8, fireproof layer 6 and hanging bars 7. Each closed cavity of the original bamboo is provided with 2 small pressure relief holes 2, and a plurality of original bamboos are densely arranged on the steel floor corrugated 5 to form a bamboo raft 1, and the upper surface of the bamboo raft 1 is laid with a wave-shaped flexible waterproof layer consistent with its shape 3. The flexible waterproof layer 3 is laid with a light clay layer 4 with the upper surface as a plane, and the wooden floor surface layer 8 is laid on the upper surface of the light clay layer 4; the gypsum board fireproof layer 6 is hung on the original bamboo layer 1 through hanging ribs 7 under. The flexible waterproof layer 3 adopts roll material to lay close to the surface of the original bamboo to fo...

Embodiment 3

[0029] Embodiment 3: as figure 1 , 2 As shown, the original fireproof bamboo floor slab includes bamboo flute 5, bamboo raft 1, flexible waterproof layer 3, light clay layer 4, fireproof layer 6 and hanging bars 7. There are 3 small pressure relief holes 2 on each closed cavity of the original bamboo, and a plurality of original bamboos are densely arranged on the bamboo floor flute 5 to form a bamboo raft 1, and the upper surface of the bamboo raft 1 is laid with a wave-shaped flexible wall that is consistent with the shape of the upper surface. The waterproof layer 3; the flexible waterproof layer 3 is laid with a light clay layer 4 whose upper surface is a plane; the bamboo raft 1 is hoisted with a gypsum board fireproof layer 6 through hanging ribs 7, and the surface of the bamboo floor corrugated 5 is equipped with a gypsum fireproof board 6. The flexible waterproof layer 3 adopts coiled material to be laid close to the surface of the original bamboo to form a wave-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com