Multi-hole foam glass carrier for fast mass transfer biological fluidized bed and preparation method and application thereof

A biological fluidized bed and porous foam technology, applied in the field of sewage treatment, porous foam glass carrier and its preparation, can solve the problem of poor dynamic turbulence between carrier and liquid phase, lower fluidized bed treatment efficiency, and easy biodegradation of polymers and other issues, to achieve the effect of improving the efficiency of sewage treatment, increasing the contact opportunities between phases, and reducing the price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

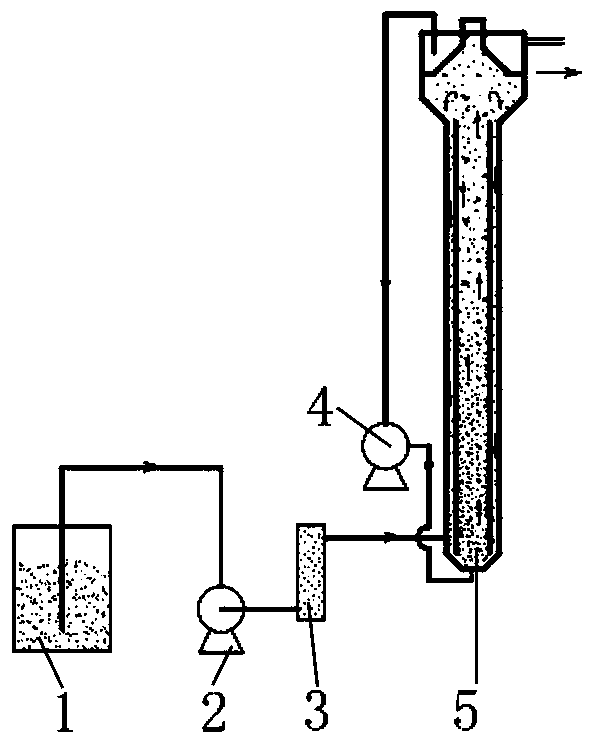

Method used

Image

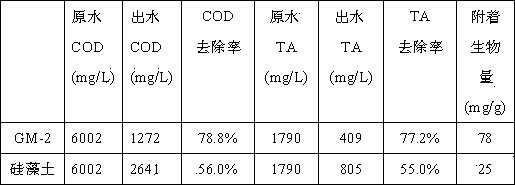

Examples

Embodiment 1

[0047] Clean the bottle glass, and after drying, ball-mill it into glass powder below 200 mesh; mix 5Kg of bottle glass powder, 1.68Kg of volcanic rock, 0.8Kg of fly ash, 0.2Kg of coal gangue, 0.5Kg of slag, Put 1Kg of iron powder, 0.5Kg of aluminum powder, 0.1Kg of polyethylene glycol-400, 0.1Kg of silicon carbide, 0.06Kg of sodium phosphate and 0.06Kg of mullite into a ball mill jar and mill to 200 mesh The following steps are added to the mold for foaming: in the preheating stage, the temperature is raised from room temperature to 300°C at a rate of 5°C / min and kept for 20 minutes; in the rapid sintering stage, the temperature is raised from 300°C to 730°C at a rate of 15°C / min and Keep warm for 10 minutes; in the foaming stage, raise the temperature from 730°C to 850°C at a rate of 9°C / min and hold for 20 minutes; After annealing to 400°C, the temperature is rapidly lowered at a rate of 12°C / min to obtain a porous foam glass carrier for rapid mass transfer biological fluid...

Embodiment 2

[0052] Clean the flat glass, and after drying, ball-mill it into glass powder below 200 mesh; mix 5Kg of flat glass powder, 1.2Kg of volcanic rock, 0.87Kg of fly ash, 0.2Kg of coal gangue, 0.7Kg of slag, and 1.07Kg of Iron powder, 0.55Kg of aluminum powder, 0.12Kg of polyvinyl alcohol, 0.14Kg of carbon black, 0.07Kg of sodium dihydrogen phosphate and 0.08Kg of borax mixture are put into a ball mill jar, and ball milled to below 200 mesh and added to a mold for Foaming: In the preheating stage, raise the temperature from room temperature to 300°C at a rate of 6°C / min and keep it warm for 25 minutes; In the soaking stage, the temperature was raised from 730°C to 860°C at a heating rate of 10°C / min and held for 25 minutes; in the rapid cooling stage, the cooling rate was 14°C / min, and the temperature was dropped to 615°C for 35 minutes; in the annealing stage, the cooling rate was 1°C / min. min, after annealing to 410°C, the temperature was rapidly lowered at a rate of 18°C / min to...

Embodiment 3

[0057] Clean the glass of discarded laboratory instruments, and ball-mill it into glass powder below 200 mesh after drying; 3Kg of discarded laboratory instrument glass glass powder, 1.5Kg of volcanic rock, 1.6Kg of fly ash, 0.8Kg of coal gangue, Put 0.65Kg of slag, 1.45Kg of iron powder, 0.65Kg of aluminum powder, 0.1Kg of polyvinyl alcohol, 0.1Kg of carbon black, 0.08Kg of sodium dihydrogen phosphate and 0.07Kg of borax mixture into the ball mill tank, and ball mill Fill the mold below 200 mesh for foaming: in the preheating stage, raise the temperature from room temperature to 310°C at a rate of 7°C / min and keep it warm for 25 minutes; in the stage of rapid sintering, raise the temperature from 310°C to 740°C and hold for 15 minutes; in the foaming stage, raise the temperature from 740°C to 870°C at a rate of 11°C / min and hold for 23 minutes; in the rapid cooling stage, cool down to 620°C and hold for 37 minutes at a rate of 15°C / min; in the annealing stage , the cooling ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com